Method for determining processing size of special-shaped checker bricks on periphery of heat storage chamber of hot blast stove

A technology for determining the method and processing size, which is applied in the direction of brick blast furnace and glass production, can solve the problems of high cost of one-time use of samples, low processing precision of samples, and low efficiency of sample nesting processing, so as to reduce mechanical shifts and achieve accurate dimensions , The effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with specific embodiments.

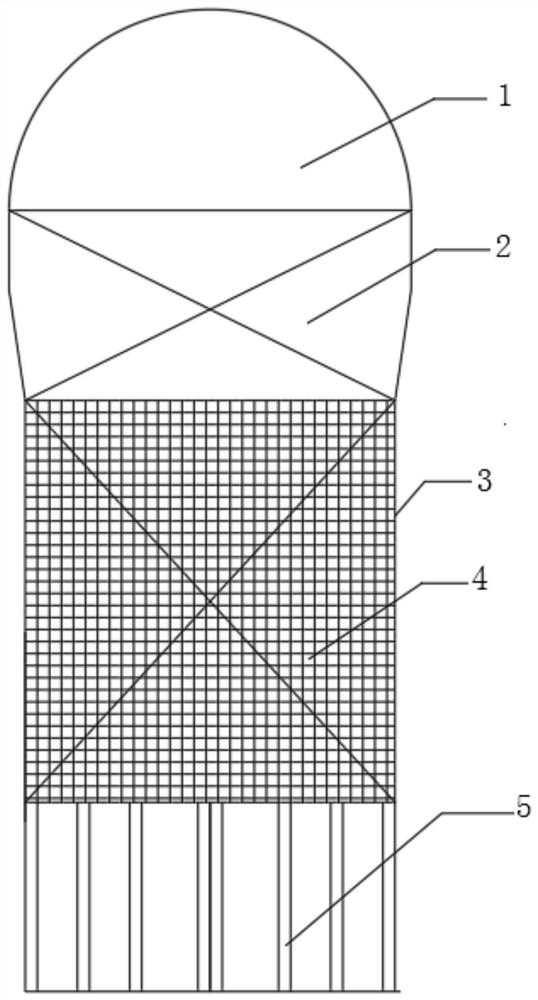

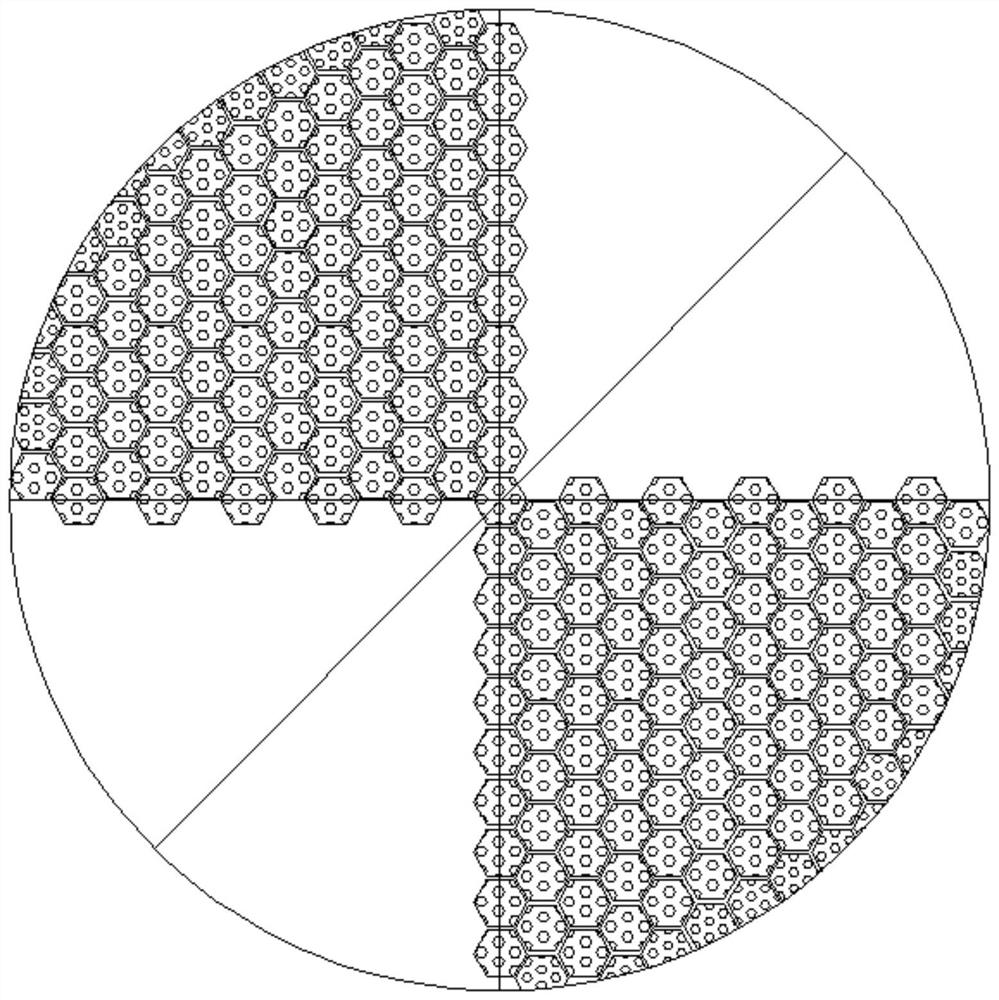

[0021] refer to Figure 1-2

[0022] In this embodiment, a method for determining the processing size of special-shaped checker bricks around the regenerator of a hot blast stove is proposed, including the following steps:

[0023] 1. According to the design drawings of the regenerator chamber of the hot blast stove, calculate the inner radius R1 of the regenerator shell 3 and the outer radius R2 of the grid brick masonry design in the regenerator chamber, and determine the surrounding grids in combination with the size of the individual bricks and the characteristics of the cross arrangement Brick plane two-dimensional model display model diagram;

[0024] 2. With the help of the planar array two-dimensional model diagram, determine the special-shaped single brick diagram formed after the intersection of the special-shaped checker bricks around the regenerator body and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com