Fire cover and combustor using same

A fire cover and top cover technology, applied in burners, gas fuel burners, applications, etc., can solve problems such as affecting ignition and fire protection, affecting service life, damaging thermocouples and ignition needles, etc., and achieving good flame stabilization effect, The effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0035] The fire cover in this embodiment can be applied to various burners. In this embodiment, the burner is taken as an example to describe in detail the fire cover and the burner to which the fire cover is applied.

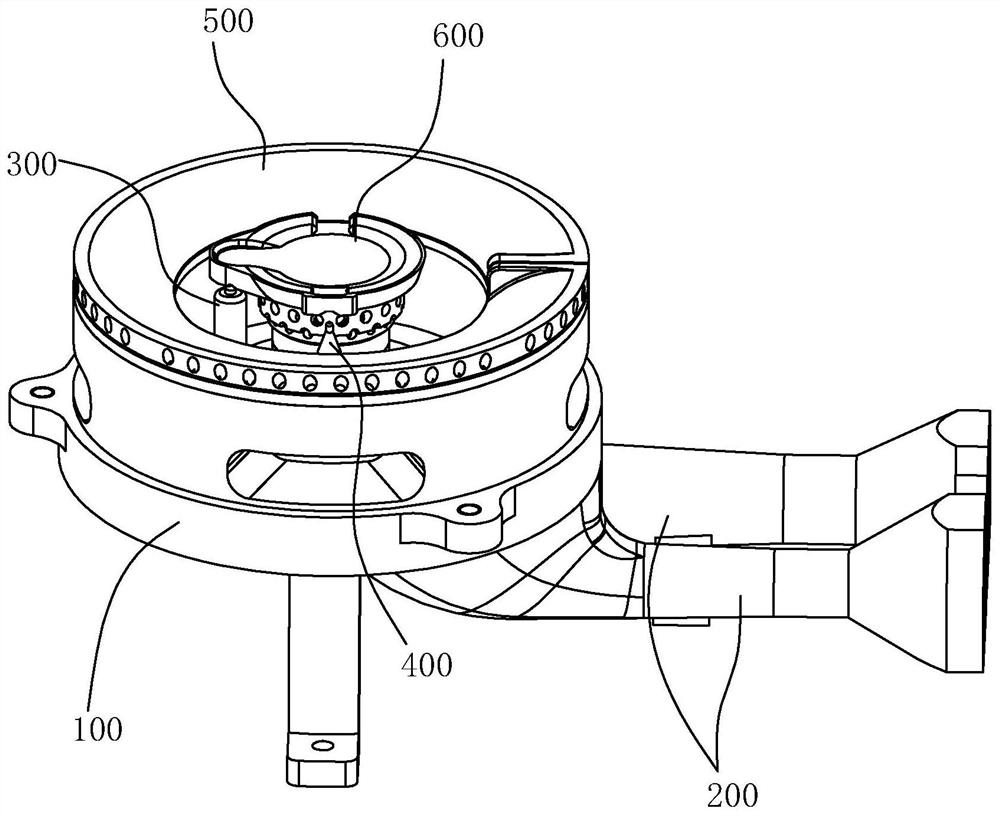

[0036] Such as figure 1 As shown, the burner in this embodiment includes a base 100, an injection tube 200, an ignition needle tube 300, and a thermocouple 400. The base 100 has an outer ring gas mixing chamber and an inner ring mixing chamber that communicate with the injection tube 200, respectively. The gas chamber and the outer ring gas mixing chamber are matched with an outer ring fire cover 500, and the ignition needle tube 300 and the thermocouple 400 are all arranged on the outer periphery of the inner ring gas mixing chamber near the inner ring gas mixing chamber, and the inner ring gas mixing chamber is matched An in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com