Damp-proof electromagnetic flow meter

An electromagnetic flowmeter and flow rate technology, which is applied in the field of flowmeters, can solve the problems of reducing the distance, not paying attention to the moisture resistance of the terminals of the electromagnetic flowmeter, reducing the cost and complexity of the system, and achieving the effect of increasing the sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

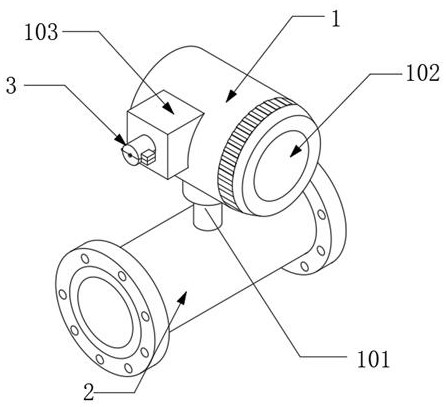

[0025] like figure 1 As shown, a moisture-proof electromagnetic flowmeter includes a main body 1, a connecting shaft 101 is welded to the bottom of the main body 1, a flow guide tube 2 is fixedly connected to the bottom of the connecting shaft 101, and a flow display screen 102 is arranged on the outer surface of the main body 1. The outer surface of the main body 1 is fixedly connected with a fixed block 103, the side of the fixed block 103 away from the main body 1 is connected with a protective component 3 and is fixedly connected with a terminal 104, the number of the terminal 104 is two, the external wire and the terminal 104 Connection, the liquid pipeline is connected with the guide tube 2, and when the internal liquid flows in the guide tube 2, the volume of the conductive medium in the tube is measured according to Faraday's law of electromagnetic induction, and displayed on the flow display screen 102 .

Embodiment 2

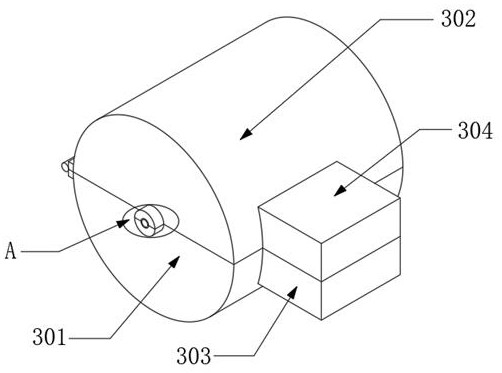

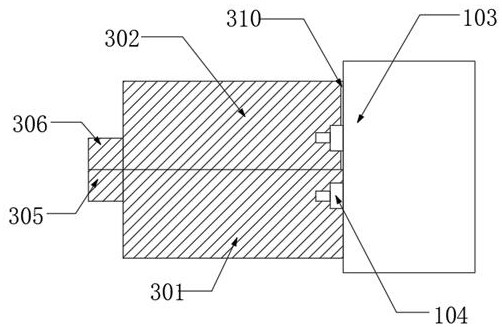

[0027] On the basis of Example 1, such as Figure 2-3 As shown, the protective assembly 3 includes a first protective shell 301 and a second protective shell 302, the first protective shell 301 is welded on the side wall of the fixed block 103, and one side of the first protective shell 301 is connected to the second protective shell 302 by a hinge. Rotationally connected, the other side of the first protective shell 301 and one side of the second protective shell 302 are respectively fixedly connected with a first limiting block 303 and a second limiting block 304, and the first limiting block 303 and the second A clamping mechanism is provided between the limit blocks 304, the second protective shell 302 is closely against the side wall of the fixed block 103, and the contact part is fixedly connected with a gasket 310, through the set first protective shell 301 and the second protective shell 302, the first protective shell 301 and the second protective shell 302 are closel...

Embodiment 3

[0029] On the basis of embodiment one and embodiment two, such as Figure 4 As shown, the side wall of the first protective shell 301 and the side wall of the second protective shell 302 are respectively welded with a first clamping block 305 and a second clamping block 306, and the top of the first clamping block 305 is provided with a first clamping groove 307, The bottom of the second clamping block 306 is provided with the second clamping groove 308 that is compatible with the first clamping groove 307, and the inner walls of the first clamping groove 307 and the second clamping groove 308 are all fixedly connected with rubber pads 309, through the provided The first clamping block 305, the second clamping block 306, the first clamping slot 307 and the second clamping slot 308 tightly squeeze the external wires entering the inside of the protection component 3, and the rubber pad 309 provided in cooperation further increases the protection component 3, prevents moist air f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com