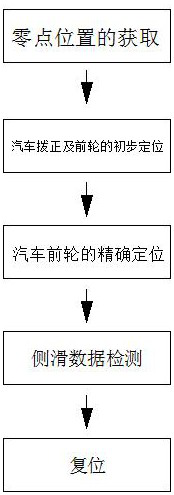

Automobile sideslip detection table with automatic positioning function and detection method

A technology of automatic positioning and detection method, applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of the accuracy of the detection results, difficulty in adjustment, and time-consuming, and achieve fast vehicle side slip detection. , The effect of accurate detection data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

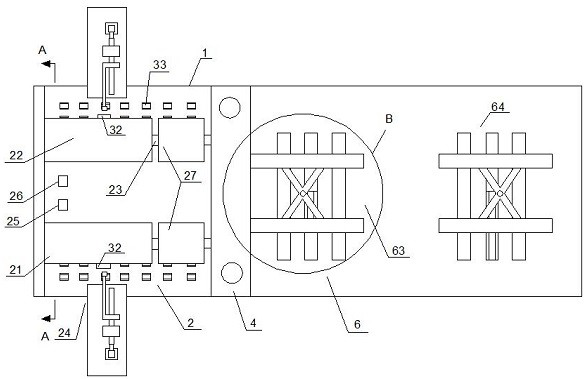

Embodiment 1

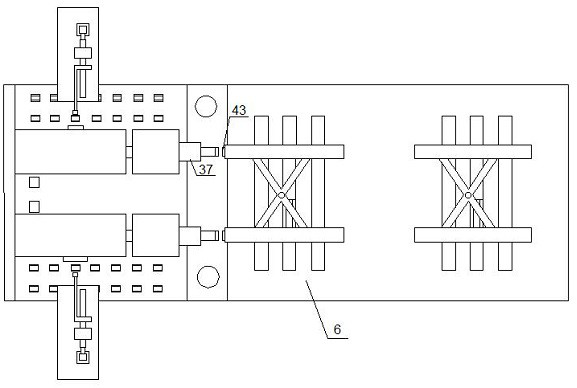

[0060] Embodiment one: if figure 1 and Figure 4 Shown, drive mechanism 24 comprises screw mandrel 30, electromagnet 31, magnet 32, push rod 44, screw mandrel seat 45, motor 46 and mounting plate 47, and mounting plate 47 is fixed on the frame 1, and screw mandrel seat 45 is fixed on On the top of the mounting plate 47, the screw mandrel 30 is rotatably connected with the screw mandrel seat 45 through the bearing, the screw mandrel 30 is vertically arranged with the left side slide plate 21, the push rod 44 is threadedly connected with the screw mandrel 30, and the push rod 44 is "L" type, Push rod 44 is arranged in parallel with screw mandrel 30, and the bottom of push rod 44 contacts with mounting plate 47, and the end of push rod 44 away from screw mandrel seat 45 is fixed with electromagnet 31, and motor 46 is fixed on the mounting plate 47, and the motor 46 The output shaft is connected to one end of the screw mandrel 30, and the side of the left slide plate 21 and the r...

Embodiment 2

[0070] The working process of the driving mechanism 24 in the second embodiment is as follows: start the motor 46, and the motor 46 drives the screw mandrel 30 to rotate. Since the push rod 44 is in contact with the mounting plate 47, the rotation degree of freedom of the push rod 44 is limited, so that the screw mandrel 30 and push rod 44 form a screw nut pair, so that push rod 44 moves along the length direction of screw rod 30; forward rotation motor 46 drives push rod 44 to move forward through screw rod 30, and drives conical connecting block 49 to approach wedge-shaped Block 48 moves, and when the tapered surface of conical connection block 49 contacts with wedge-shaped surface one 52, due to the guiding action of wedge-shaped surface one 52, under the effect of force applied continuously by conical connection block 49, wedge-shaped block 48 is made close to magnet 32 Setting, the connecting spring 57 is compressed, when the tapered connecting block 49 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com