Automatic assembling and buckling device for elastic buckle, and control method thereof

An automatic assembly and elastic buckle technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as material falling off, circuit board deformation, and chip failure on the circuit board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

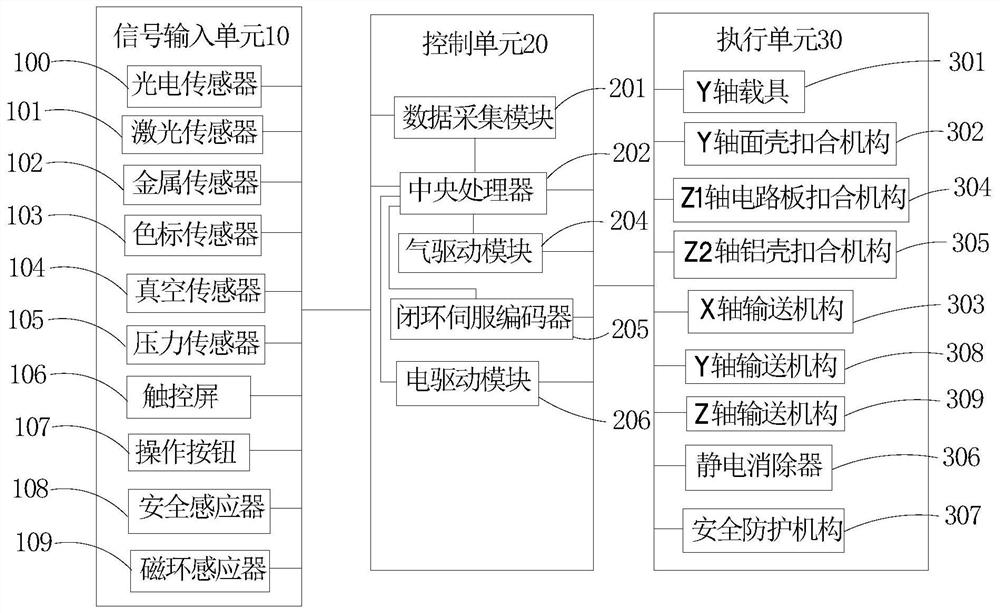

Method used

Image

Examples

Embodiment 1

[0129] A control method for automatic assembly of elastic buckles based on the above-mentioned automatic assembly and fastening device for elastic buckles is carried out according to the following steps:

[0130] Step 1, start: turn on the device power switch (set on the device panel), turn on the air source switch (not shown in the figure), the system is initialized, and each unit is in the standby state (at this time, the standby indicator 3075 light is yellow, such as Figure 15 shown);

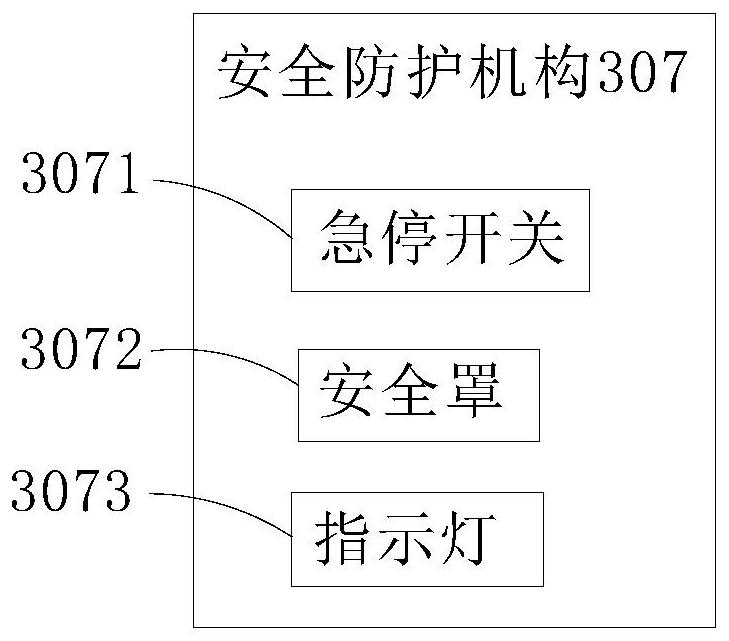

[0131] Step 2, safety protection: there is an emergency stop switch 3071 on the panel of the device, press this switch for emergency stop in case of abnormality, and a vacuum status display 3181 (divided into two displays for circuit board vacuum and aluminum shell vacuum); There is a safety cover 3072, and there is a safety grating 3074 on the front (set on both sides of the front of the safety cover 3072), when there is external interference, it will automatically cut off all dangerous i...

Embodiment 2

[0146] Step 1 to step 8 of the present embodiment 2 are the same as embodiment 1, the difference is from step 9 to step 11, specifically as follows:

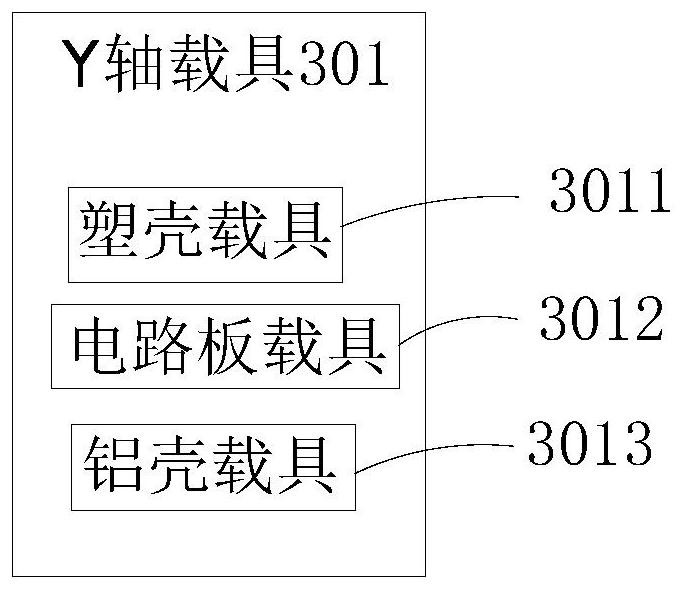

[0147] Step 9, circuit board suction: Z1-axis circuit board fastening mechanism 304 integrates vacuum suction cup 318, color mark sensor 103, pressure sensor 105 and sliding table cylinder 310, Z1-axis circuit board fastening mechanism 304 is lowered to the circuit board carrier 3012 , the color sensor 103 detects the heat dissipation silica gel (not shown in the figure) on the circuit board 314. If there is silica gel, it is normal. The touch screen 106 synchronously prompts that the carrier has no missing parts. The control panel 106 simultaneously prompts the missing part of the carrier. Under normal circumstances, the vacuum suction cup 318 fits the circuit board 314 to carry out negative pressure suction. The pressure sensor 105 detects the pressure state of the feedback circuit board 314. If the pressure exceeds the safe p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap