A high-power microwave effect test device for a miniature multi-rotor UAV

A multi-rotor unmanned aerial vehicle and high-power microwave technology, which is used in aircraft component testing and other directions, can solve the problem of inability to simulate the flight state of unmanned aerial vehicles, and achieve the effect of high-precision microwave power density control and precise effect phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

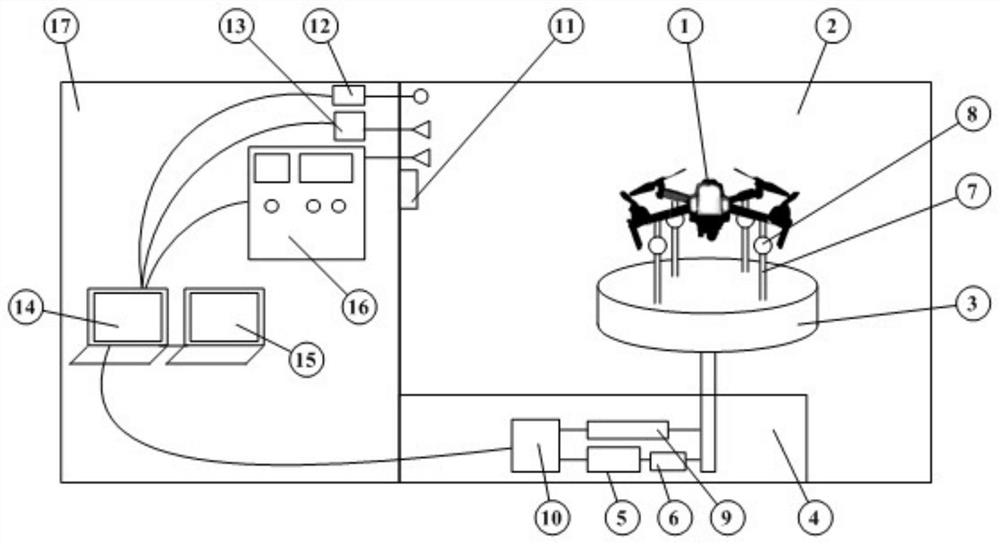

[0036] refer to figure 1 As shown, the present invention discloses a high-power microwave effect test device for a miniature multi-rotor unmanned aerial vehicle. Device control system 14 , ground workstation 15 , HPM irradiation environment generation module 16 and electromagnetic shielding room 17 .

[0037] Preferably, the simulated flight platform is used to provide a simulated real flight environment for the UAV 1 to be tested. The microwave anechoic chamber 2 is used to provide a test place. The video monitoring module 12 is used to complete the attitude monitoring of the UAV 1 .

[0038] The global positioning signal generating module 13 is configured to generate a positioning signal for a set position and a set altitude for the UAV 1 to be tested. The ground workstation 15 is used to control the UAV 1 . The HPM radiation environment generating module 16 is configured to apply an HPM radiation field with set parameters to the UAV 1 to be tested. Wherein, HPM refers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com