Anchoring-thickness-adjustable height-adjusting support

An adjustable and height-adjusting technology, which is applied to bridge parts, erecting/assembling bridges, bridges, etc., can solve problems such as different support heights, thread force deformation, height adjustment failure, etc., to avoid thread extrusion deformation, avoid The effect of stress concentration and high frequency adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

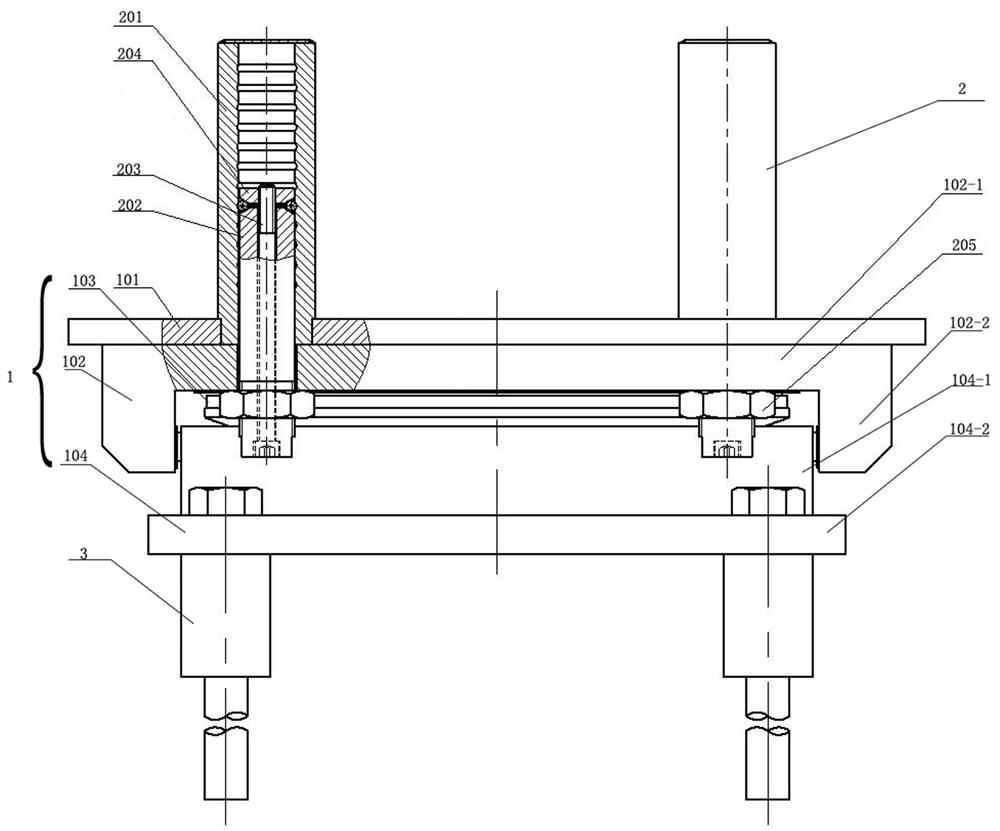

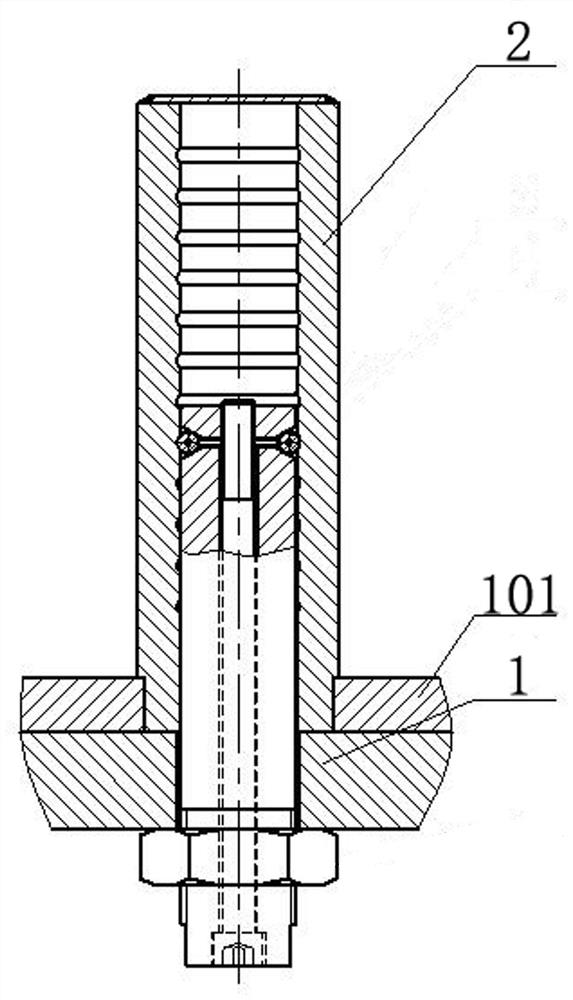

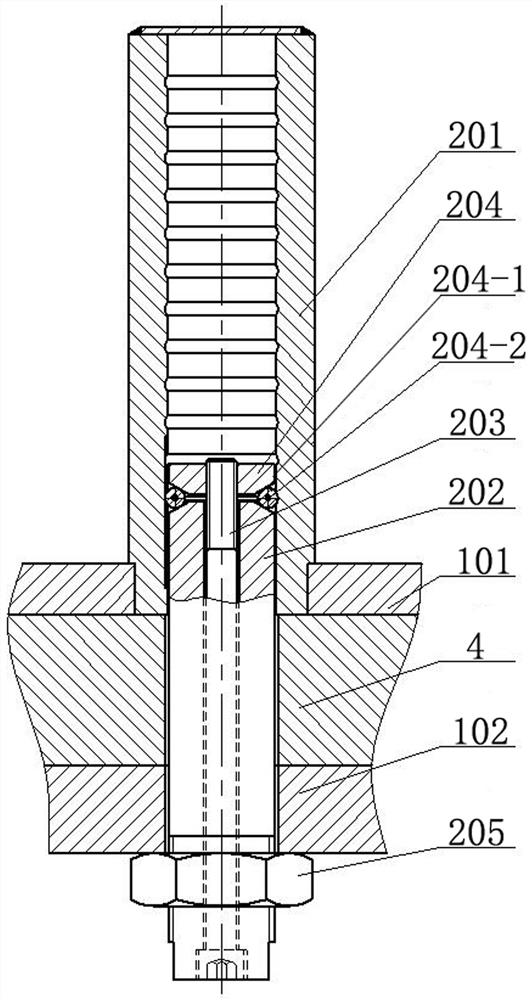

[0030] Such as figure 1 , Figure 4 , Figure 5 , it mainly consists of upper sleeve 201, fixed plate 204-1, elastic block 204-2, spring 206, adjusting bolt 203, anchor rod 202, beam bottom embedded plate 101, support body, nut 205, boss 207, etc. composition.

[0031] The lower part of the sleeve 201 in this embodiment is provided with a stepped outer circle structure, which is embedded in the installation hole of the beam bottom embedded plate 101, and is cast on the bottom of the beam together with the beam bottom embedded plate 101 to form a beam body anchor.

[0032] The inner hole of the sleeve 201 in this embodiment matches the anchor rod 202 and the outer surface of the fixing plate 204-1 with the inner hole of the sleeve 201. In the relaxed state, components such as the anchor rod 202 can be placed in the inner hole of the sleeve 201. Free movement along the axis. The inner hole of the sleeve 201 is provided with multiple annular grooves. When adjusting the height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com