Spiral stabilizing mechanism suitable for transformer and implementation method thereof

A transformer and stable technology, applied in the field of transformers, can solve problems such as high limitations, time-wasting, and inability to adjust the limit, and achieve the effect of convenient use, flexible operation, and convenient height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

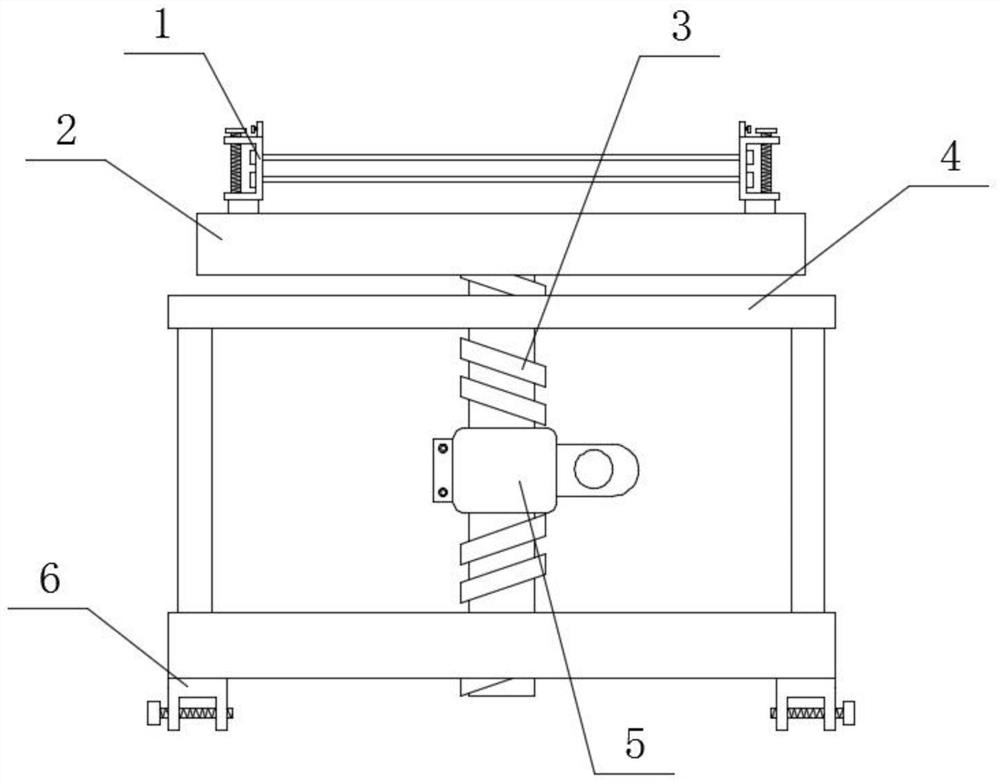

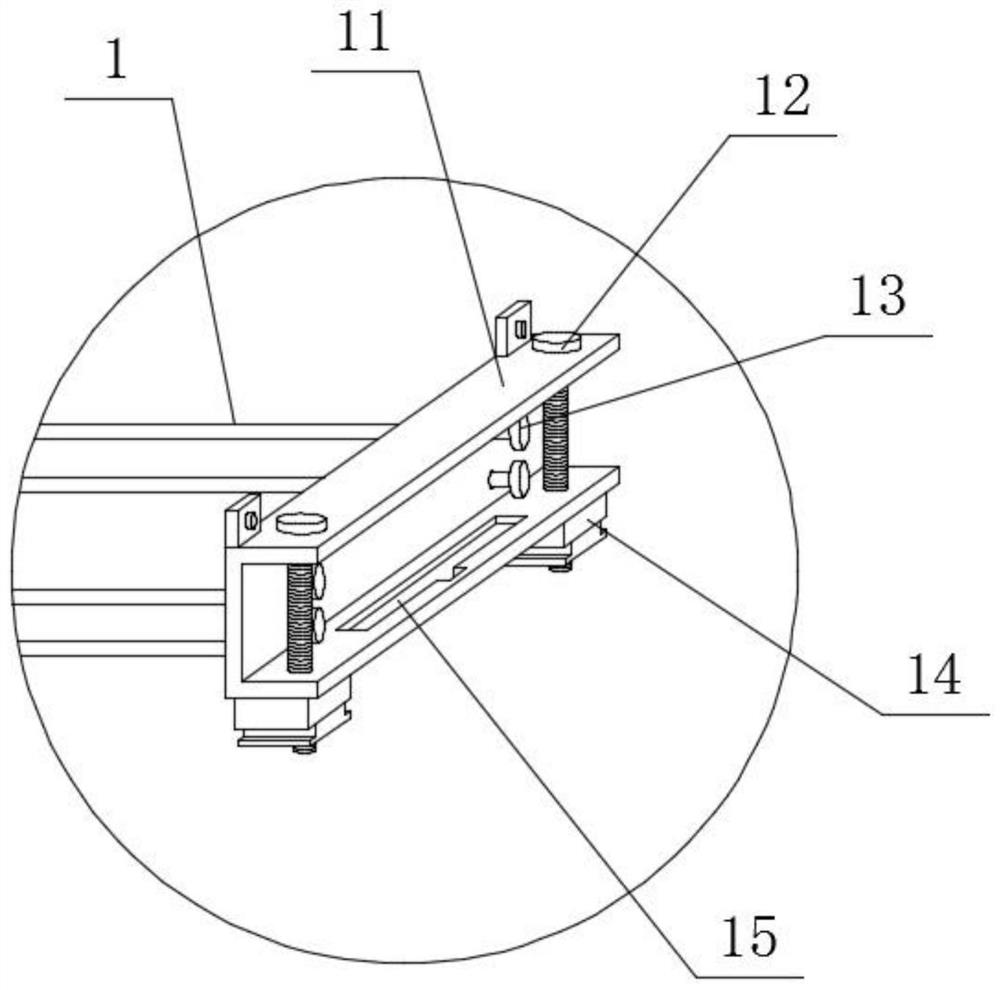

[0026] Such as Figure 1-2 As shown, a spiral stabilization mechanism suitable for transformers includes a frame 4, the bottom end surface of the frame 4 is fixedly connected with a bottom clip 6, and the inner surface of the frame 4 is movably connected with a screw rod 3 through a helical thread, and the screw rod 3 The top end surface is connected with the long plate 2 through the shaft rotation, and the top end surface of the long plate 2 is slidably connected with the limit clamp 1 through the chute. The limit clamp 1 includes a clamp body 11, and the top end surface of the clamp body 11 is movably connected with a long rod through a thread. 13, and the right end face of the clip body 11 is movably connected with a fixed screw 12, the inner side of the right end face of the clip body 11 is provided with a groove 15, and the bottom end face of the clip body 11 is fixedly connected with a slider 14.

[0027] When in use, the transformer that needs to be limited can be place...

Embodiment 2

[0029] Such as Figure 1-2 As shown, a spiral stabilization mechanism suitable for transformers includes a frame 4, the bottom end surface of the frame 4 is fixedly connected with a bottom clip 6, and the inner surface of the frame 4 is movably connected with a screw rod 3 through a helical thread, and the screw rod 3 The top end surface is connected with the long plate 2 through the shaft rotation, and the top end surface of the long plate 2 is slidably connected with the limit clamp 1 through the chute. The limit clamp 1 includes a clamp body 11, and the top end surface of the clamp body 11 is movably connected with a long rod through a thread. 13, and the right end face of the clip body 11 is movably connected with a fixed screw 12, the inner side of the right end face of the clip body 11 is provided with a groove 15, and the bottom end face of the clip body 11 is fixedly connected with a slider 14.

[0030] The inner side of the right end face of the limit clip 1 is provid...

Embodiment 3

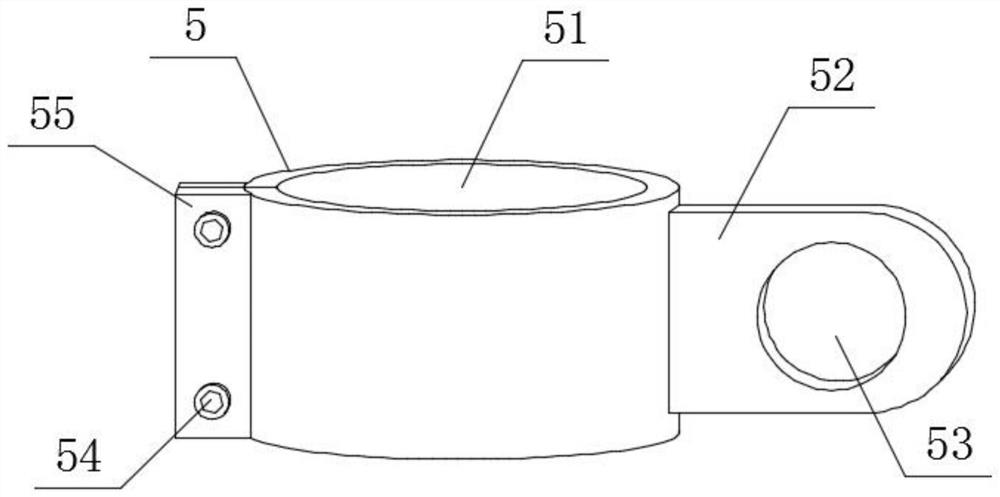

[0032] Such as Figure 1-3 As shown, a spiral stabilization mechanism suitable for transformers includes a frame 4, the bottom end surface of the frame 4 is fixedly connected with a bottom clip 6, and the inner surface of the frame 4 is movably connected with a screw rod 3 through a helical thread, and the screw rod 3 The top end surface is connected with the long plate 2 through the shaft rotation, and the top end surface of the long plate 2 is slidably connected with the limit clamp 1 through the chute. The limit clamp 1 includes a clamp body 11, and the top end surface of the clamp body 11 is movably connected with a long rod through a thread. 13, and the right end face of the clip body 11 is movably connected with a fixed screw rod 12, the inside of the right end face of the clip body 11 is provided with a groove 15, and the bottom end face of the clip body 11 is fixedly connected with a slider 14, and the connecting ring 5 includes There is a ring 51, the outer surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com