AGV-based intelligent warehouse management system for electric power materials

A warehouse management system and electric power material technology, applied in the field of electric power material intelligent warehouse management system, can solve the problems of high labor intensity, high input cost, difficult system update and structural reconstruction, etc., to save manpower and material resources, improve Management level and efficiency, structure simplification and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

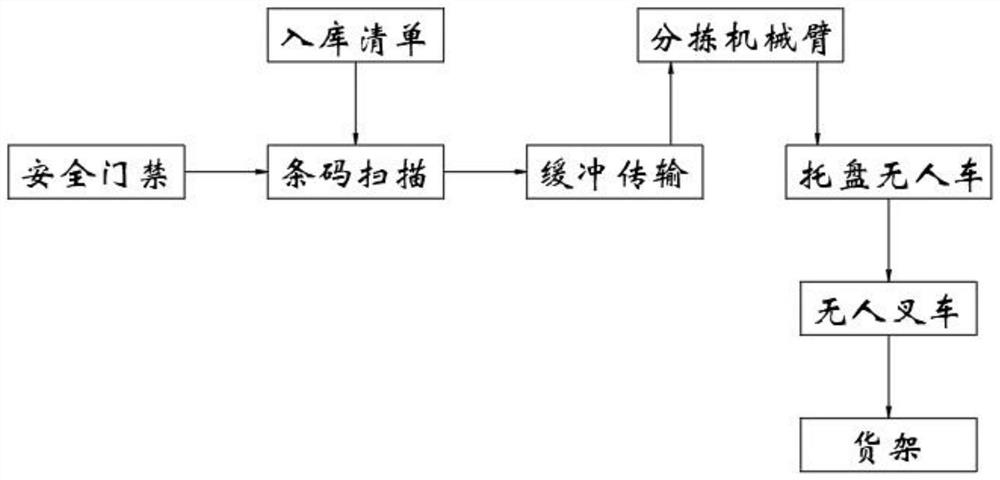

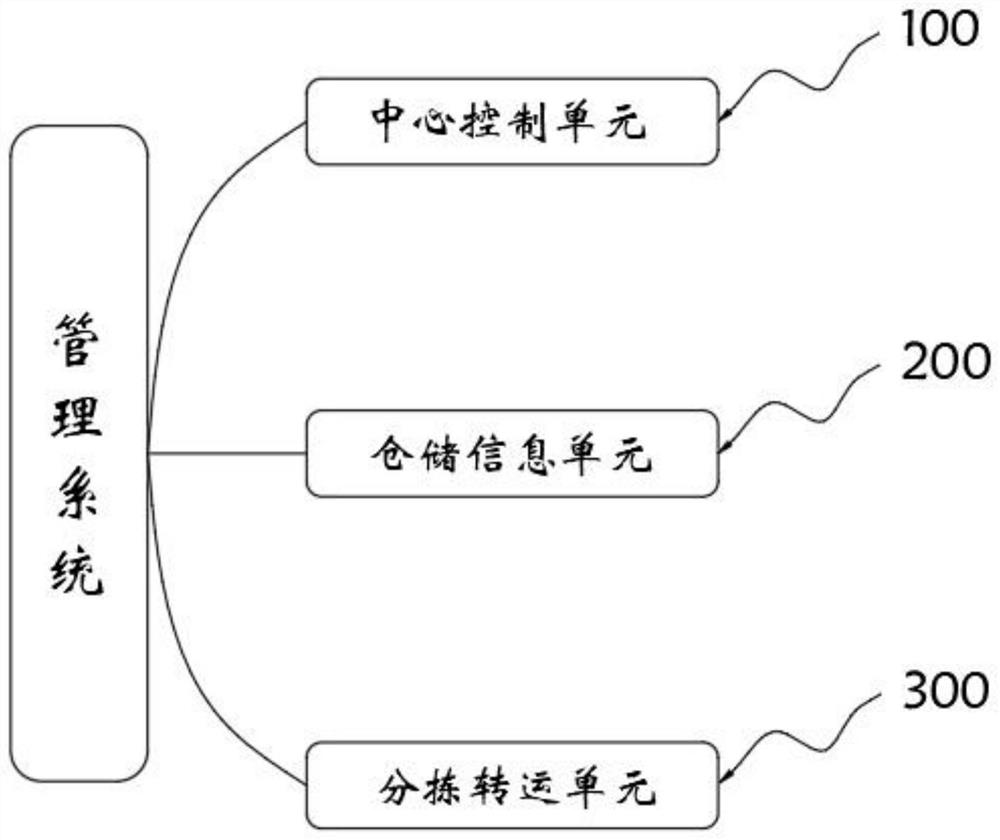

[0037] Such as Figure 1-9 As shown, this embodiment provides an AGV-based intelligent warehouse management system for power materials, including a central control unit 100, a warehouse information unit 200, and a sorting and transferring unit 300; the central control unit 100, the warehouse information unit 200, and the sorting and transferring unit 300 are sequentially connected through digital signal communication; the central control unit 100 is used to uniformly control and manage the storage system and dispatch materials; the storage information unit 200 is used to collect and enter, compare and analyze, classify and store material information in the warehouse; The transfer unit 300 is used to control and manage various automatic devices for sorting and transporting materials.

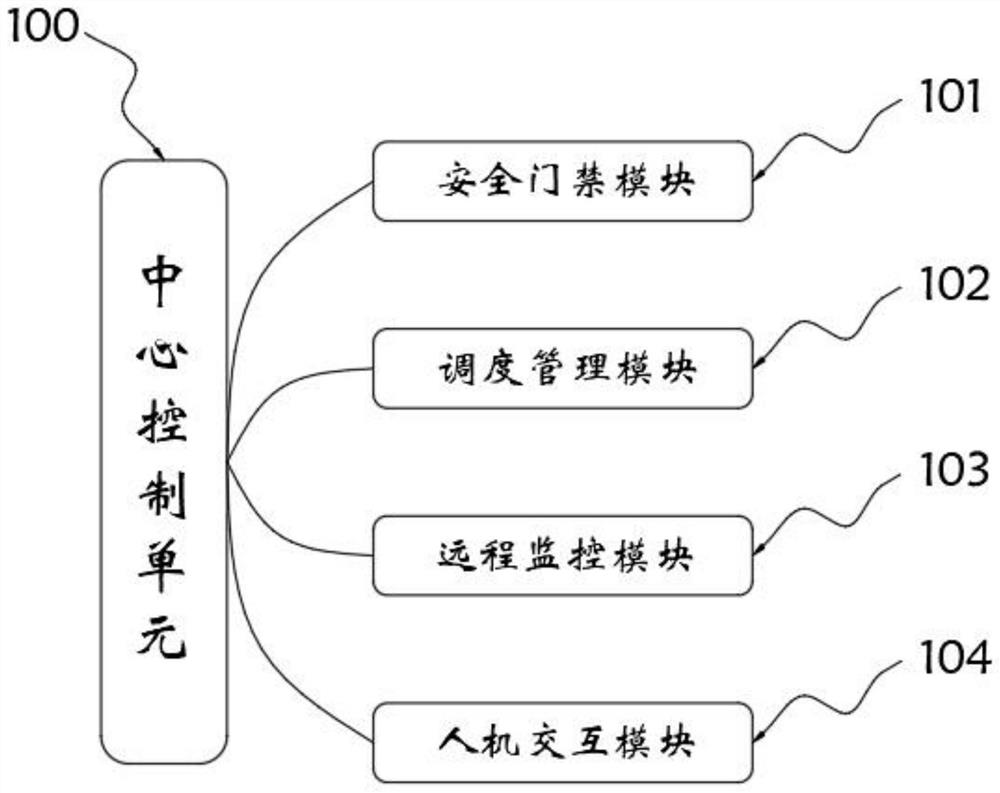

[0038]In this embodiment, the central control unit 100 includes a security access control module 101, a scheduling management module 102, a remote monitoring module 103, and a human-computer inte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap