Deep-ditch high-ridge full-film-mulching cultivation method

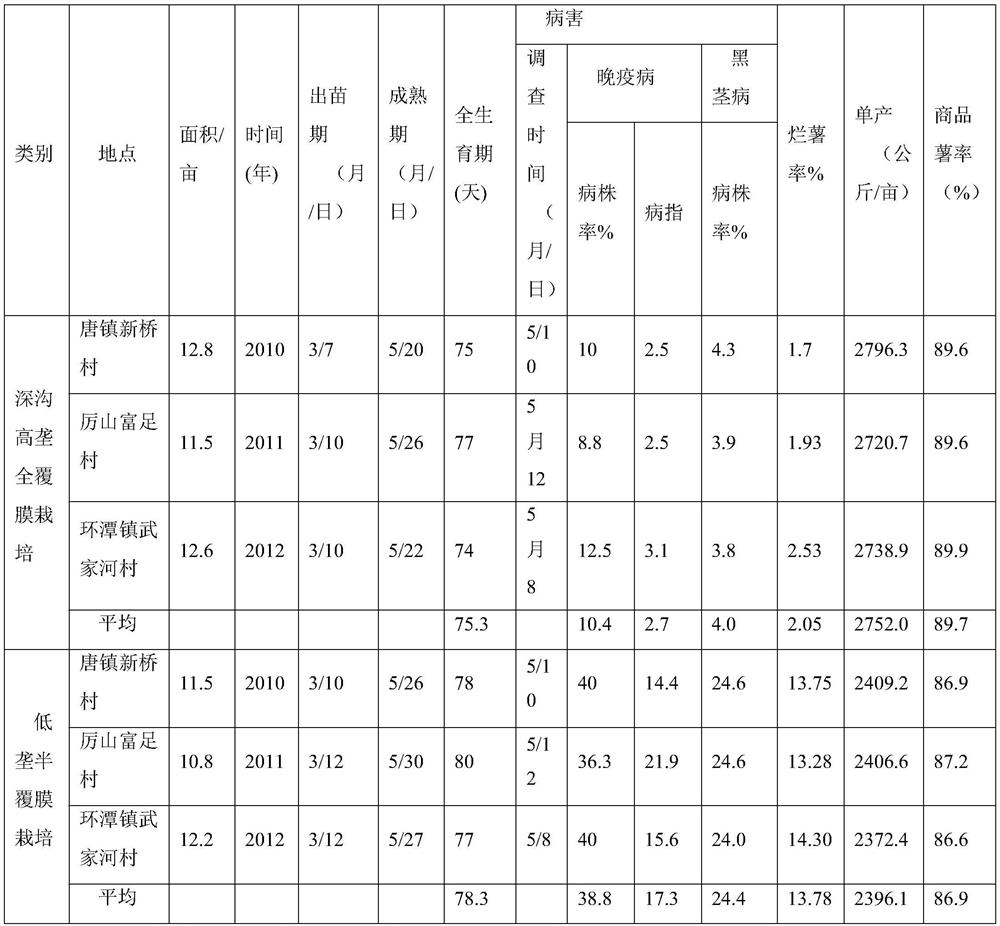

A cultivation method and full-film-covering technology are applied in the field of full-film-covering cultivation in deep furrows and high ridges, which can solve the problems of the climate unsuitable for southern China, which is dry in winter and waterlogged in spring, the utilization rate of fields and tidal flats is not high, and the structure of winter crops is single, etc. Achieve the effect of improving scientificity, improving fertilizer utilization rate, and reducing the incidence of late blight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Aiming at the problems existing in the prior art, the present invention provides a deep ditch and high ridge fully film-covered cultivation method. The present invention will be described in detail below in conjunction with the charts.

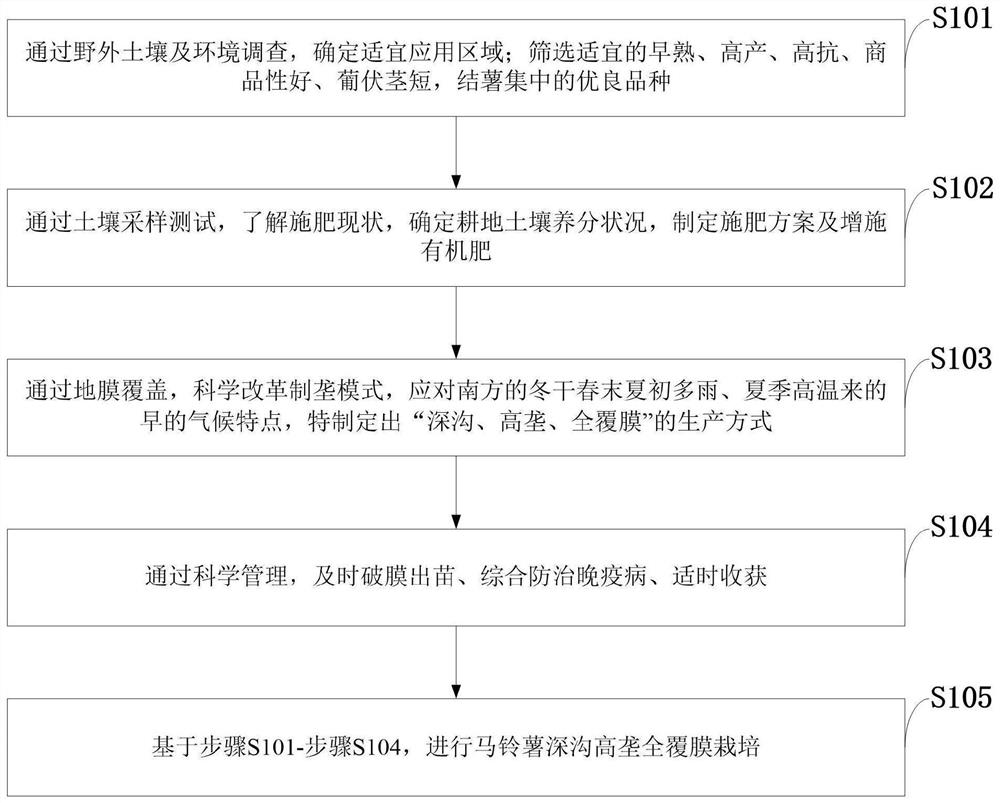

[0034] Such as figure 1 As shown, the deep ditch and high ridge full film-covering cultivation method provided by the embodiment of the present invention comprises the following steps:

[0035] S101: Through field soil and environmental surveys, determine suitable application areas; select suitable fine varieties with early maturity, high yield, high resistance, good commerciality, short grape stems, and concentrated tubers.

[0036] S102: Through soil sampling and testing, understand the current situation of fertilization, determine the nutrient status of cultivated land soil, formulate fertilization plan and increase the application of organic fertilizer.

[0037] S103: Through mulching, scientifically reform the ridge-making model, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com