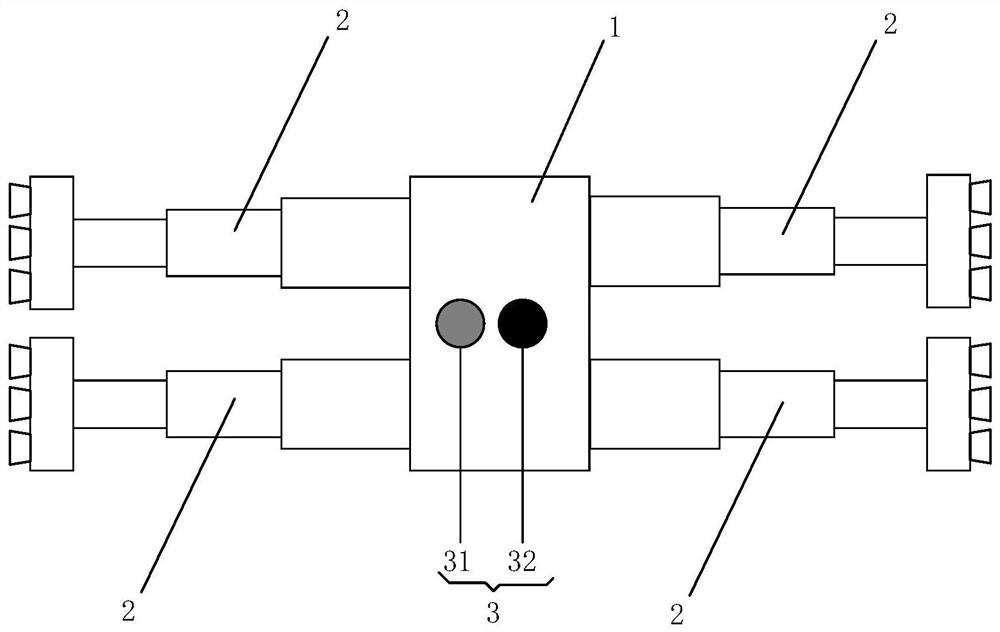

A power inspection robot and its driving method

An inspection robot and power inspection technology, applied in the field of robotics, can solve the problems of narrow cable trench environment, insufficient human inspection and supervision, etc., and achieve the effect of good control, simple steps, and precise trajectory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

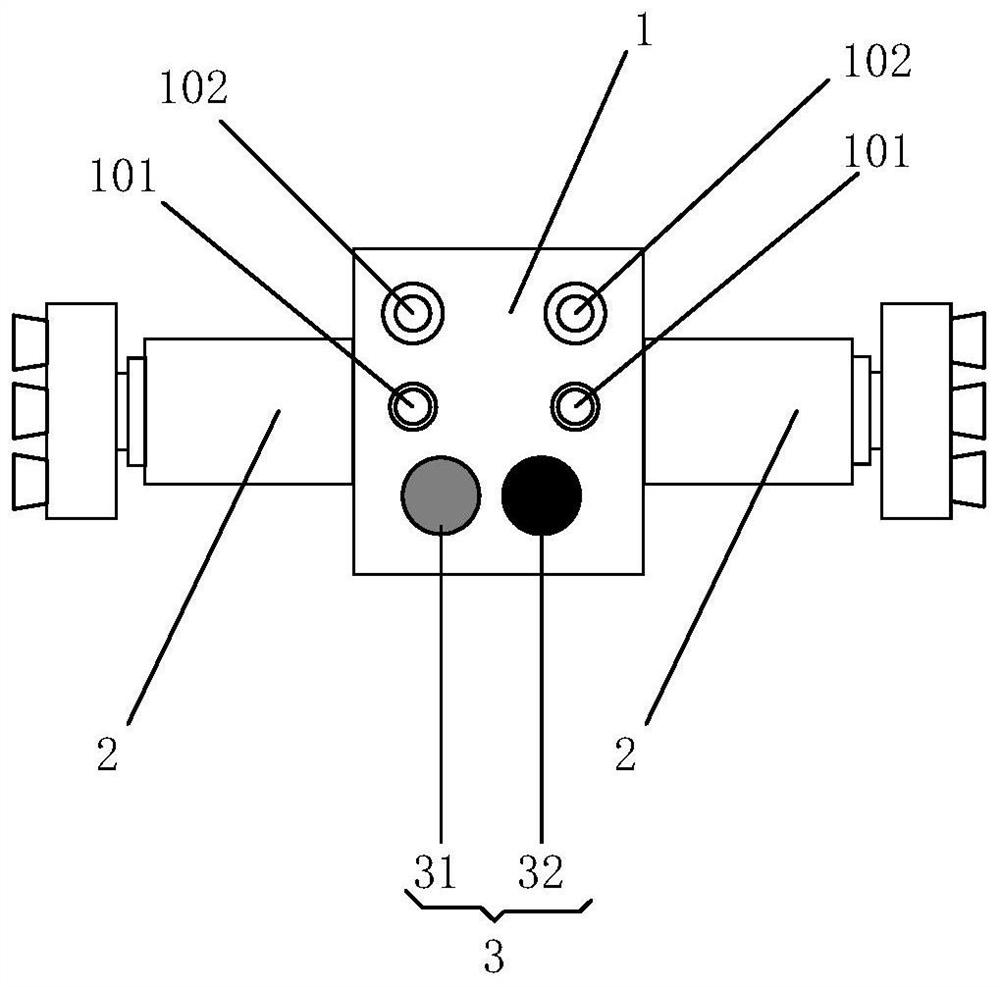

[0026] The present invention is further described below in conjunction with the accompanying drawings of the description and the specific preferred embodiments, but it does not

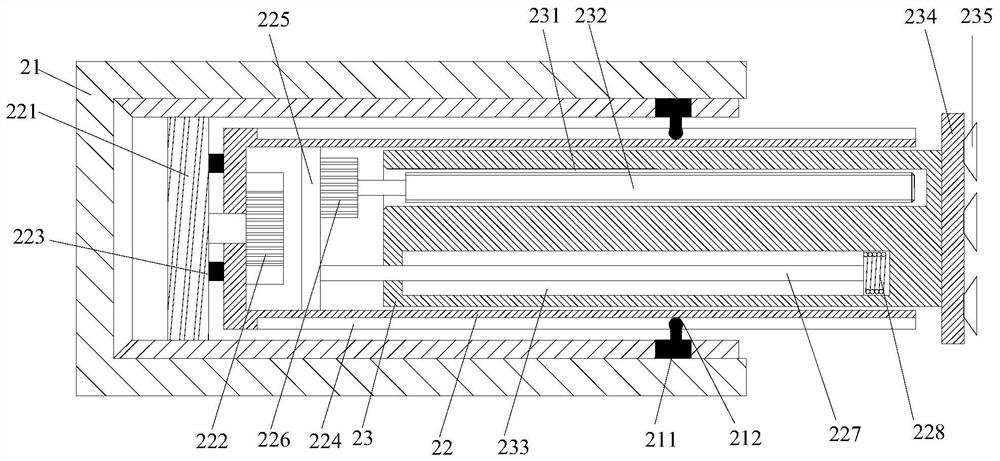

[0033] As shown in FIG. 2, the telescopic arm 2 of the present embodiment includes a fixed section 21 and a first telescopic section 22, and the fixed section 21 is a tubular knot

[0034] As shown in FIG. 2, in order to prevent the first motor 222 and the second motor 226 from influencing each other, in this embodiment, the first telescopic

[0035] As shown in FIG. 2, in this embodiment, a small amount of space is provided between the side wall of the hole of the fixed section 21 and the outer wall of the first telescopic section 22.

[0037] As shown in FIG. 2, in this embodiment, a rubber ring 223 is provided between the bottom end of the first threaded rod 221 and the first telescopic section 22,

[0038] As shown in FIG. 2, in order to achieve the limit for the second telescopic section 23, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com