3D printer piston system

A 3D printer and piston technology, applied in the field of additive manufacturing, can solve problems such as high friction between the sealing device and the cylinder liner, reduced printing quality, and crawling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

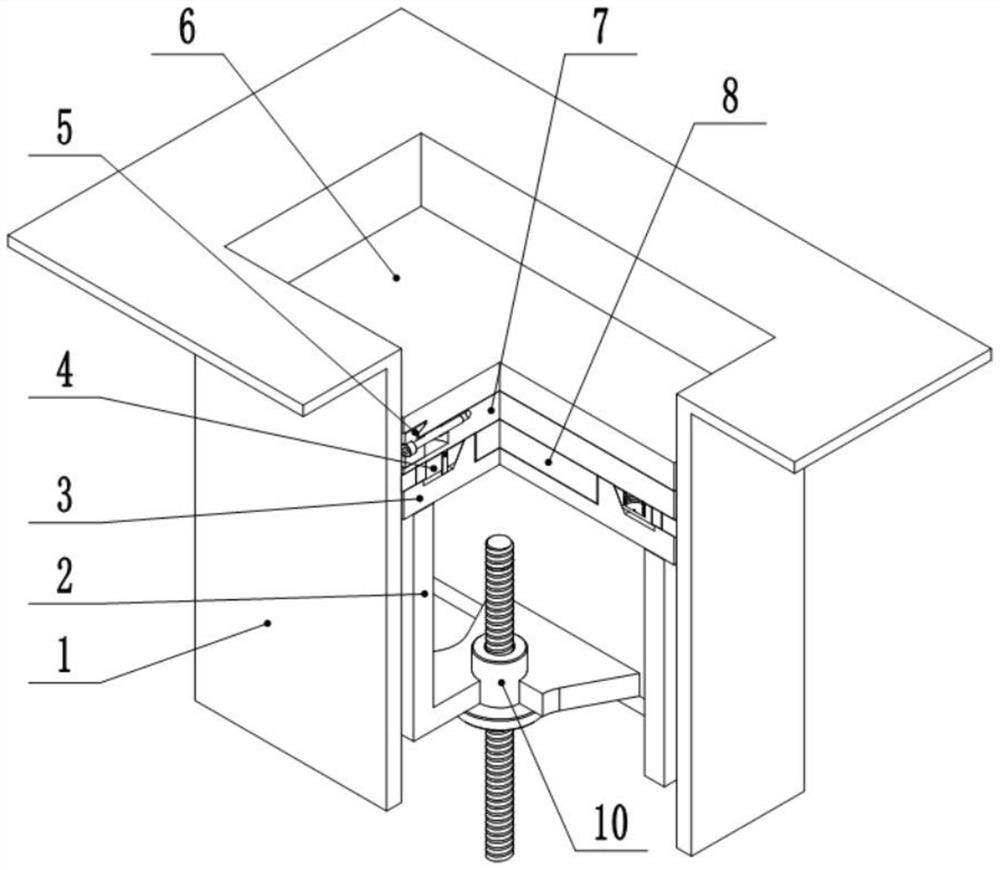

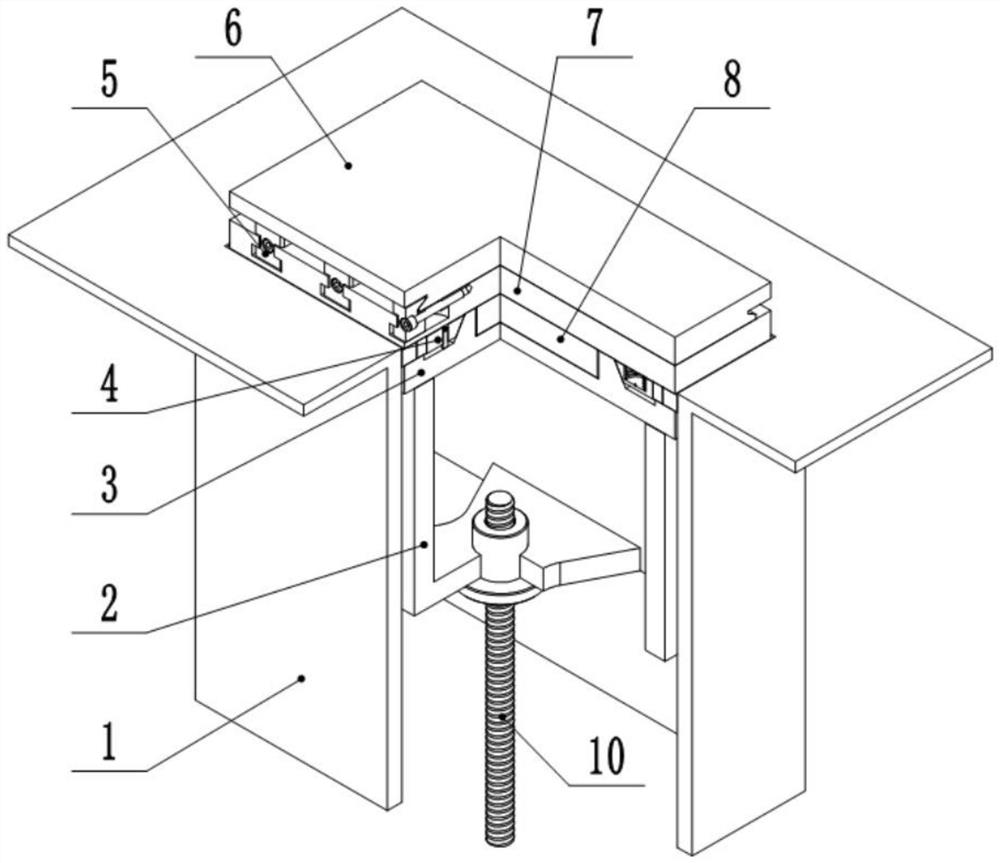

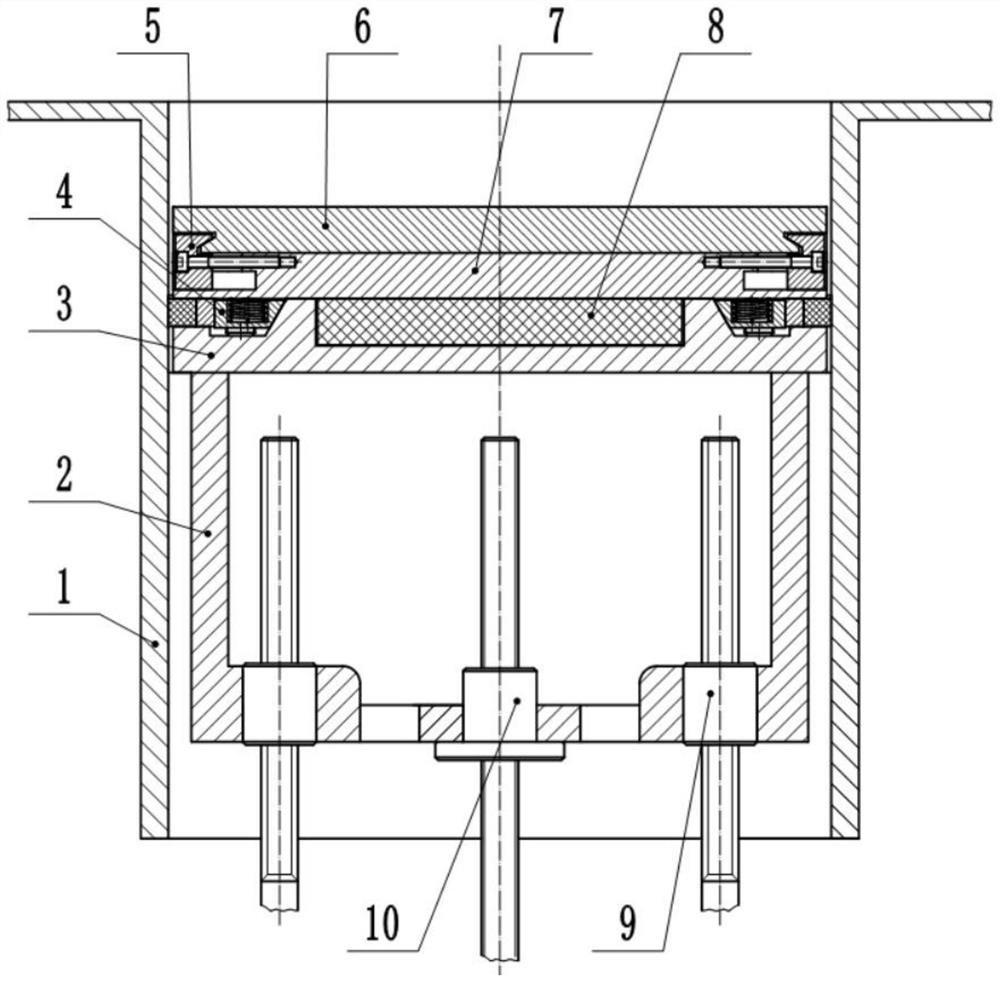

[0021] The embodiment of the present invention provides a 3D printer piston system, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the 3D printer piston system includes a cylinder liner 1 , a piston skirt 2 , a piston plate 3 , a sealing device 4 , a base plate locking mechanism 5 , a base plate 6 , a cover plate 7 , a constant temperature device 8 , a guide mechanism 9 and a drive system 10 .

[0022] The cylinder liner 1 is fixedly connected to the body of the 3D printer. The inner and lower part of the cylinder liner 1 is a piston skirt 2. The piston skirt 2 is provided with at least one set of guiding mechanisms 9. The lower part of the piston skirt 2 is provided with a drive system 10. Plate 3 , the piston plate 3 is fixedly connected with the piston skirt 2 , and the peripheral outer edge of the piston plate 3 matches the inner diameter of the cylinder liner 1 . In the specific implementation process, the peripheral outer edge of the piston plate 3 is s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap