Combined plugging device for tunnel lining

A plugging device and a combined technology, which is applied in the direction of tunnel lining, tunnel lining, shaft lining, etc., can solve the problems of inconvenient tightness, large welding volume, hidden safety hazards, etc. The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

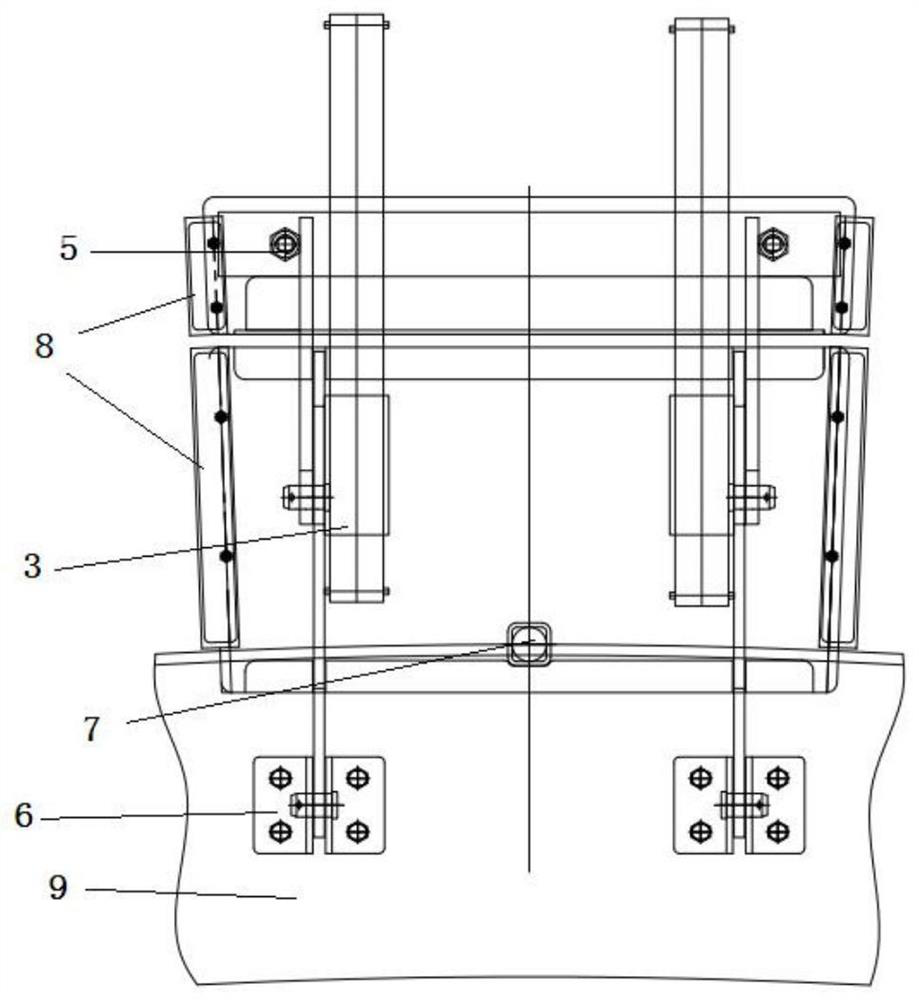

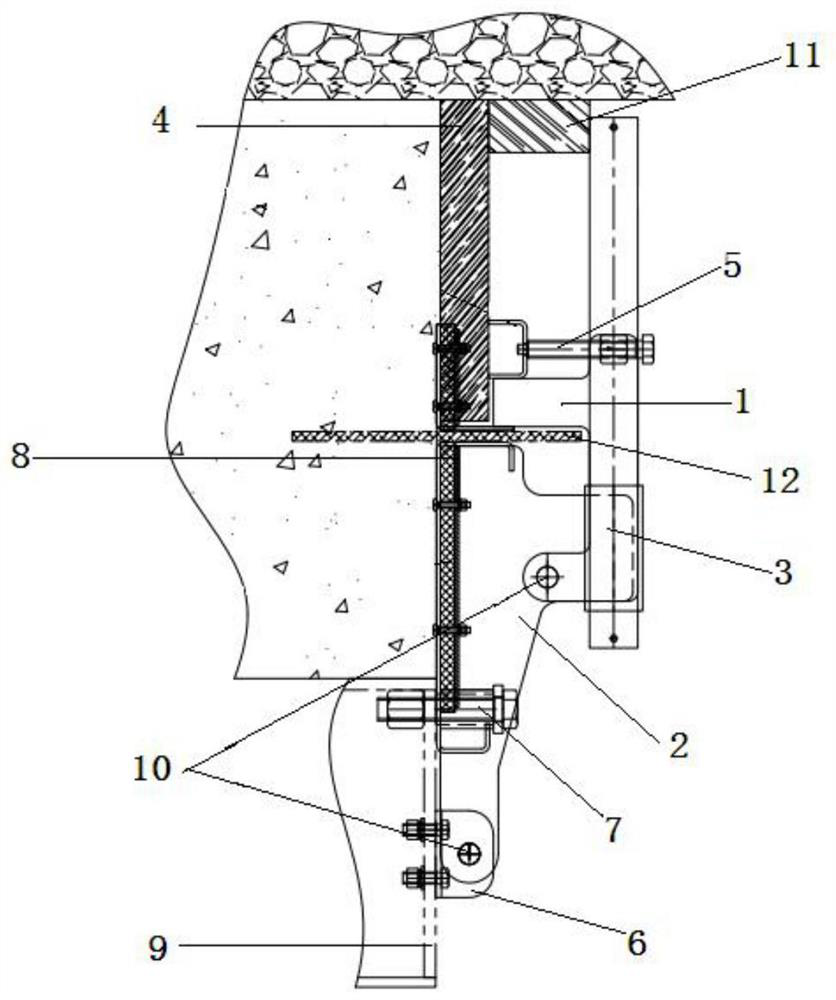

[0030] A combined sealing device for tunnel lining, its specific structure is as follows Figure 1-Figure 5 As shown, it mainly includes the upper plugging die 1, the lower plugging die 2 and the strut assembly 3, the details are as follows:

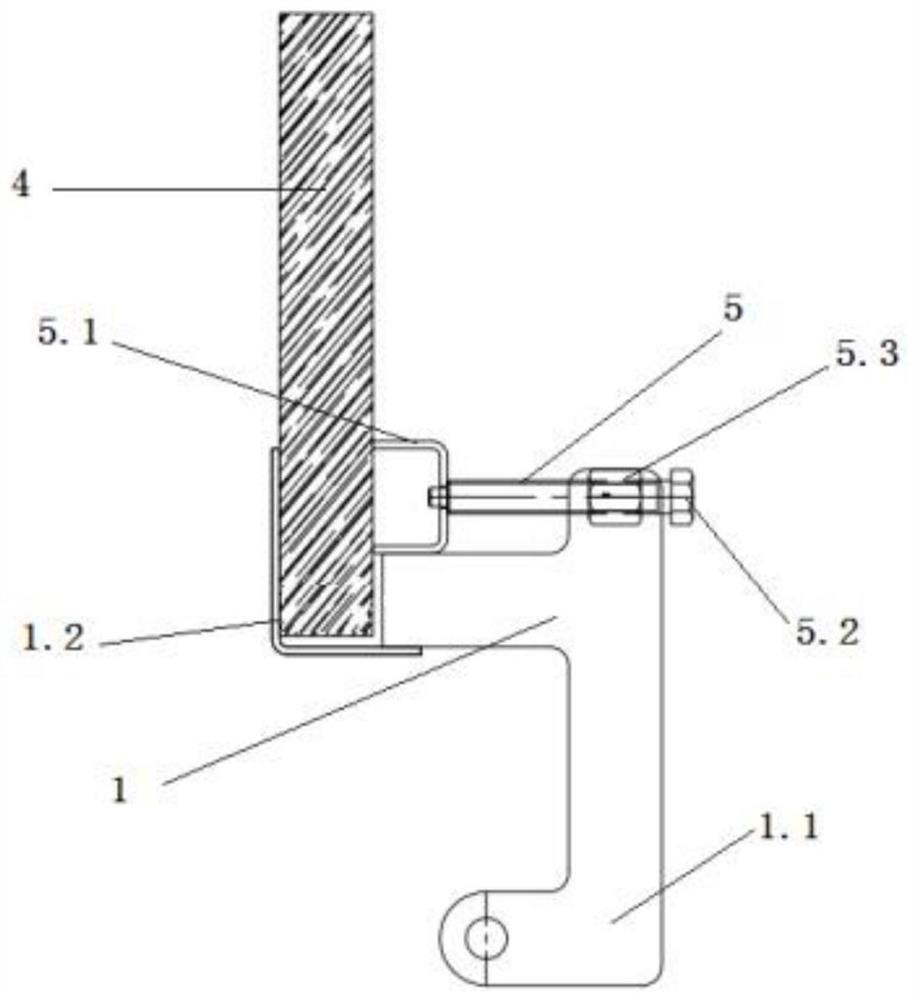

[0031] The upper plugging die 1 includes an upper plugging die hinge ear 1.1 and a mounting groove 1.2 for installing the plugging part 4, which facilitates the positioning and limiting of the plugging part 4 during installation. For details, see figure 2 and image 3 .

[0032] The lower plugging die 2 includes the lower plugging die hinge ear 2.1, the upper plugging die 1 and the lower plugging die 2 pass through the upper plugging die hinge ear 1.1, the lower plugging die hinge ear 2.1 and the connector 10 (such as a pin Shaft) is hinged, so that the upper plugging mold 1 can rotate and swing around the connecting piece 10 relative to the lower plugging mold 2, so as to realize the mold erecting and demoulding operations. The bloc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap