Dynamic calibration method for checkweigher

A dynamic calibration, checkweigher technology, applied in the direction of weighing equipment testing/calibration, etc., can solve problems such as the difference in the movement of the standard weights, the difference between the calibration weight level and the real product weight, the wear of the standard weights, etc., to achieve the calibration process. Simple and effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

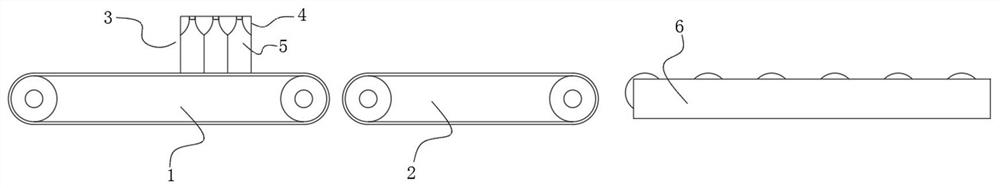

[0013] An embodiment of a dynamic calibration method for a checkweigher such as figure 1 As shown: the method includes the following steps. In the first step, the on-site product to be sorted is weighed by a standard weighing device, and the product to be sorted 3 includes a product container and liquid or granular items contained in the product container; The second step is to make the weighed products to be sorted pass through the transmission weighing end 2 of the checkweigher to be calibrated, by comparing the weight of the products to be sorted obtained by the checkweigher with the weight obtained by the standard weighing device The true weight of the product to be sorted calibrates the checkweigher.

[0014] In this embodiment, the checkweigher is used on a beverage filling production line, so the product to be sorted is a beverage bottle 5 with a beverage inside, and multiple beverage bottles are packaged together by a heat shrinkable film 4 . The standard weighing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com