A valve structure and an independent gas-sealed double-layer ash unloading valve

An ash discharge valve and air-sealing technology, which is applied in the field of valve structure and independent air-sealed double-layer ash discharge valve, can solve the problems of air leakage of the valve body and the spool ash discharge valve, damage to the negative pressure environment of the equipment, and easy wear of the spool. , to achieve the effect of low maintenance cost, good air tightness and long service life of the valve core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

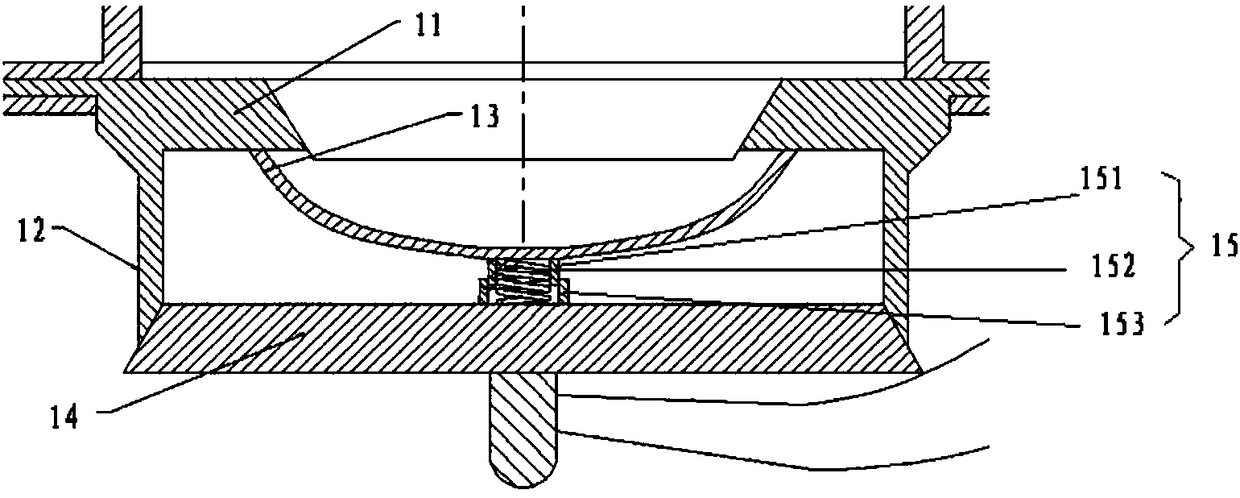

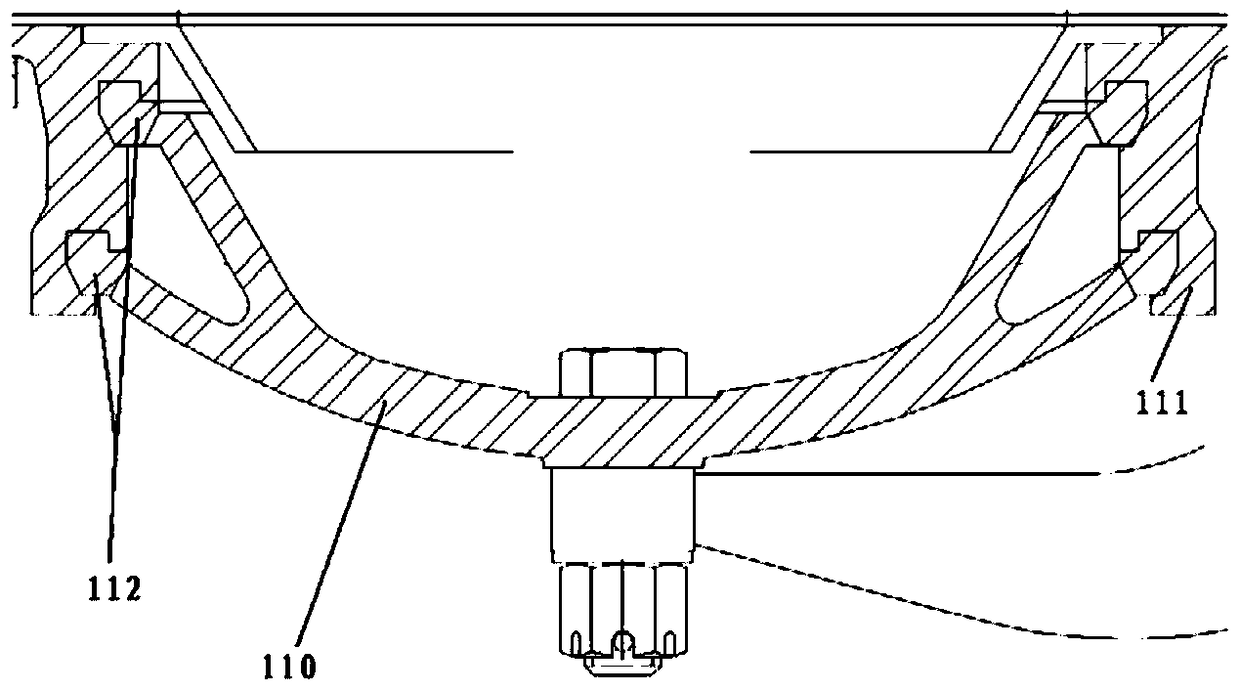

[0027] like figure 2 As shown, a valve structure provided by Embodiment 1 of the present invention includes a valve core and a valve body. The valve core is installed in the valve body. The elastic seat 15 between the cover 13 and the air seal cone 14, the shape of the leakproof cover 13 is bowl-shaped, and the air seal cone 14 is a truncated conical shape; the valve body includes an inner seat 11 and an outer seat 12, and the shape of the inner seat 11 is Ring plate shape, the shape of the outer seat 12 is cylindrical, the inner seat 11 is connected on the inner wall of the outer seat 12; the leak-proof cover 13 is located below the inner seat 11, and the cover edge of the leak-proof cover 13 is in contact with the inner seat 11 to cut off the Material flow, the lower end surface of the outer seat 12 is in contact with the conical surface of the air seal cone 14. to shut off the gas flow.

[0028] Of course, the leak-proof cover can also be replaced by other types of leak-...

Embodiment 2

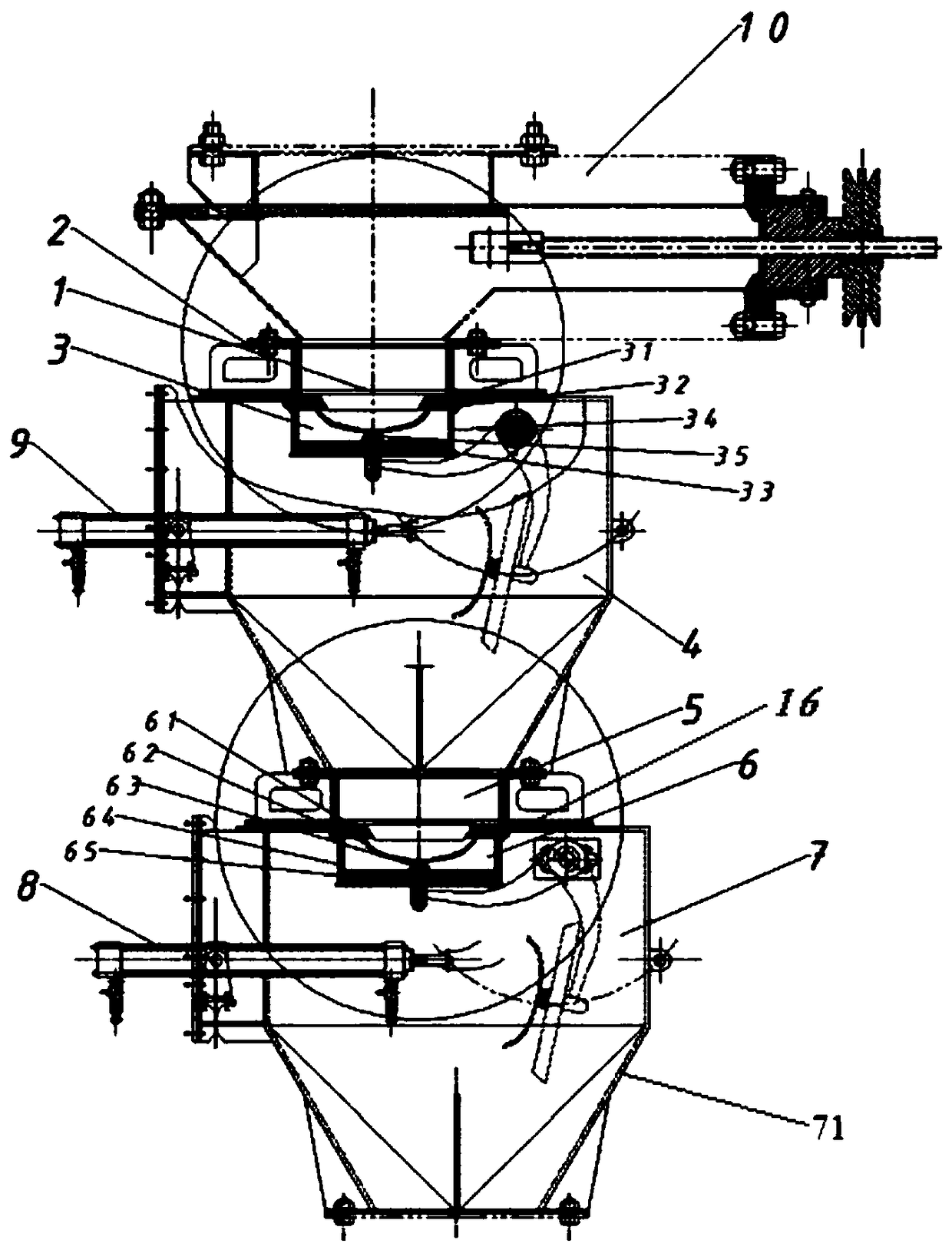

[0032] like image 3 As shown, the independent air-tight double-layer ash unloading valve provided by the second embodiment of the present invention includes the ash box 4, the upper valve actuator 9, the lower valve actuator 8, the discharge box 7 and the two valve structures in the first embodiment , are the upper valve 3 and the lower valve 6 respectively, the upper valve 3 is located in the ash box 4 and connected to the top of the ash box 4, and the upper valve actuator 9 is arranged on the side wall of the ash box 4 and connected to the bottom of the upper air seal cone 33, so as to Control the opening and closing of the upper valve 3; the lower valve 6 is located in the discharge box 7 and connected with the top of the discharge box 7, and the lower valve actuator 8 is arranged on the side wall of the discharge box 7 and connected with the bottom of the lower air seal cone 65 to Control the opening and closing of the lower valve 6; the top of the discharge box 7 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com