Supporting structure for supporting separation bearing

A release bearing and supporting structure technology, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of increasing clutch operating force, increasing wear of the separating hub, worsening operating feeling, etc., to improve operating feeling, reduce production costs, The effect of reducing the operating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

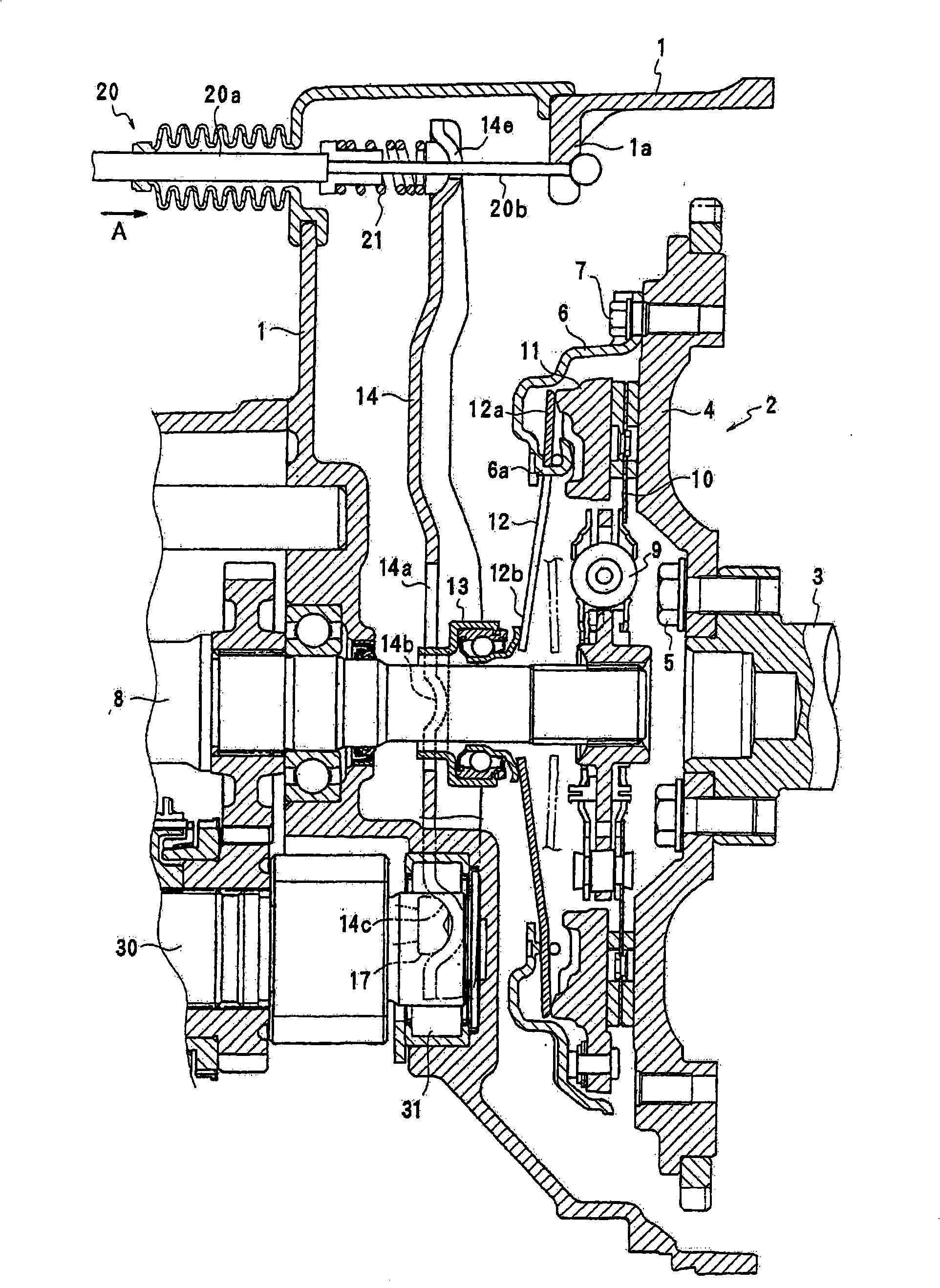

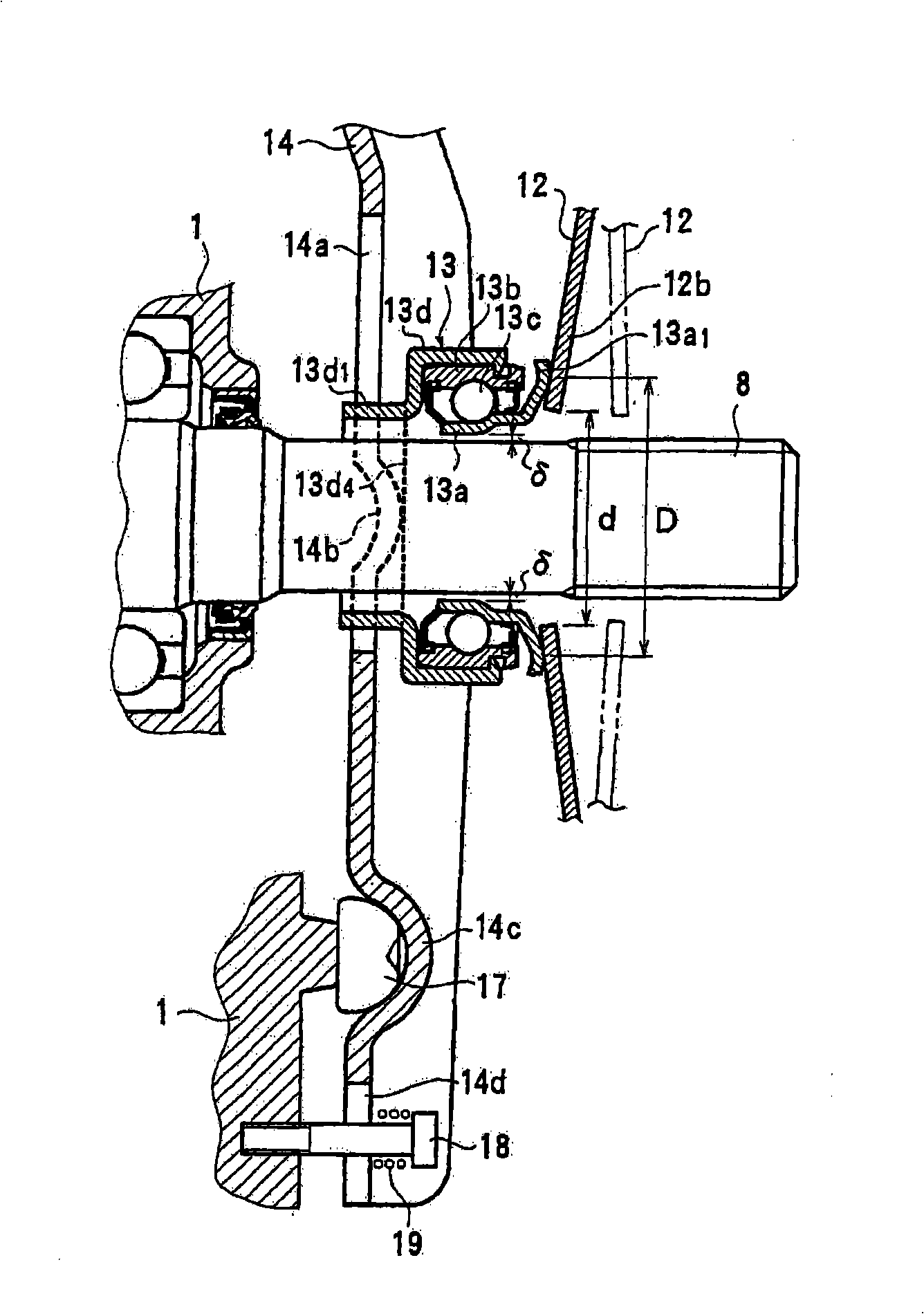

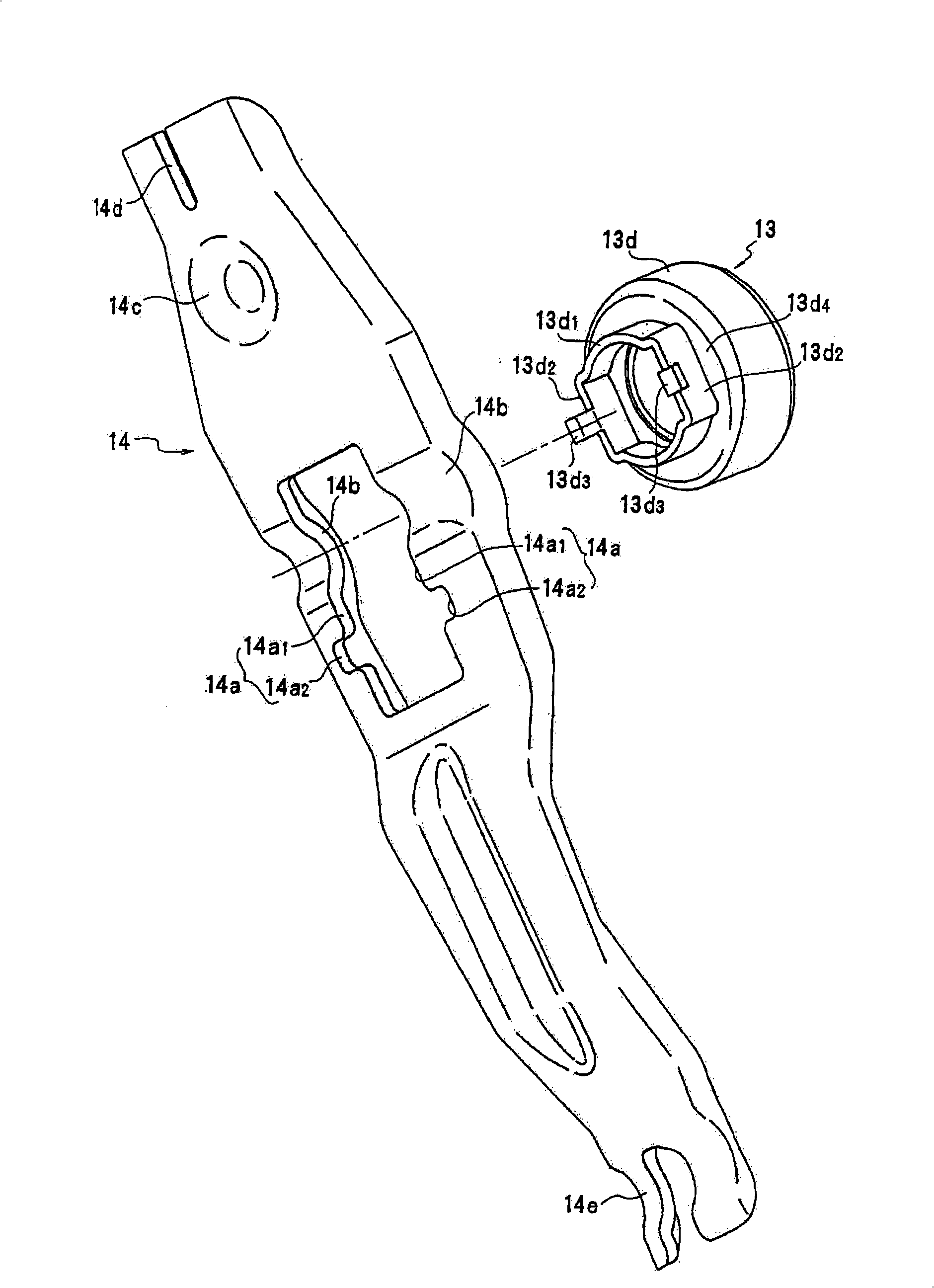

[0020] figure 1 A clutch device for an automotive manual transmission is shown as one of the exemplary embodiments of the present invention. A dry single-plate clutch 2 is accommodated in a front cover 1 which is a part of the transmission housing. The clutch 2 includes a flywheel 4, a clutch cover 6, a clutch disc 10, a pressure plate 11, a diaphragm spring 12, a release bearing 13, a release fork 14, and the like.

[0021] The flywheel 4 is fastened to the rear end 3 of the engine output shaft (drive shaft) by bolts 5 , and the clutch cover 6 is fastened to the rear surface of the flywheel 4 by bolts 7 . The input shaft (driven shaft) 8 of the manual transmission is arranged coaxially with the engine output shaft 3 . Its front end portion is inserted into the axially central portion of the clutch cover 6 . The clutch disc 10 is attached to the input shaft 8 so as to be rotatable together with the input shaft 8 via the torsion damper 9 . The pressure plate 11 and the diap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com