Locking wire contact element for preventing screw from disengaging

A contact piece and screw technology, which is applied to the field of locking wire contact pieces for preventing the screw from coming out, can solve the problems of weakened thread strength, easy threading, insufficient effective number of threads, etc., so as to achieve the effect of enhancing the meshing strength and improving the connection reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

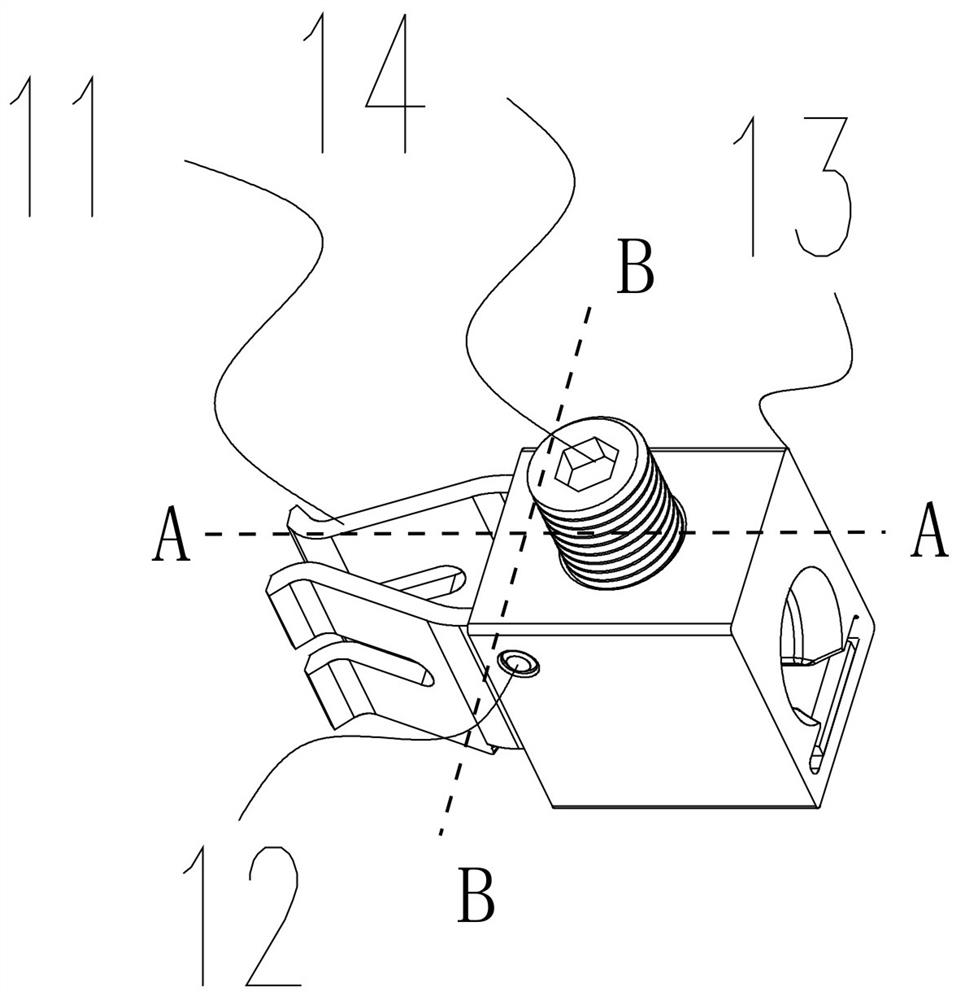

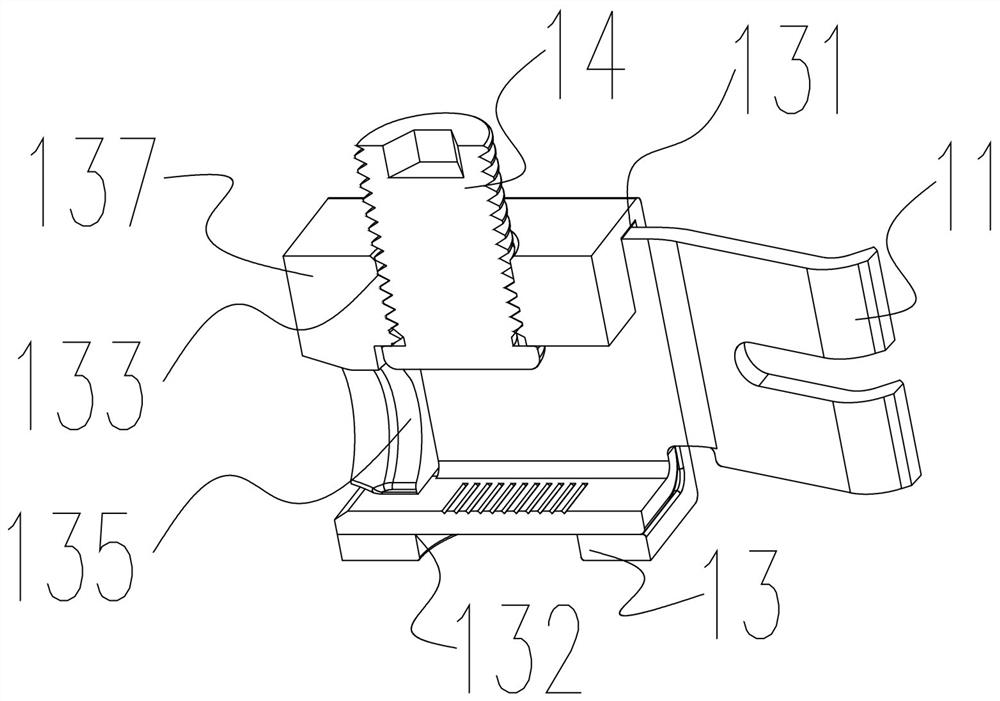

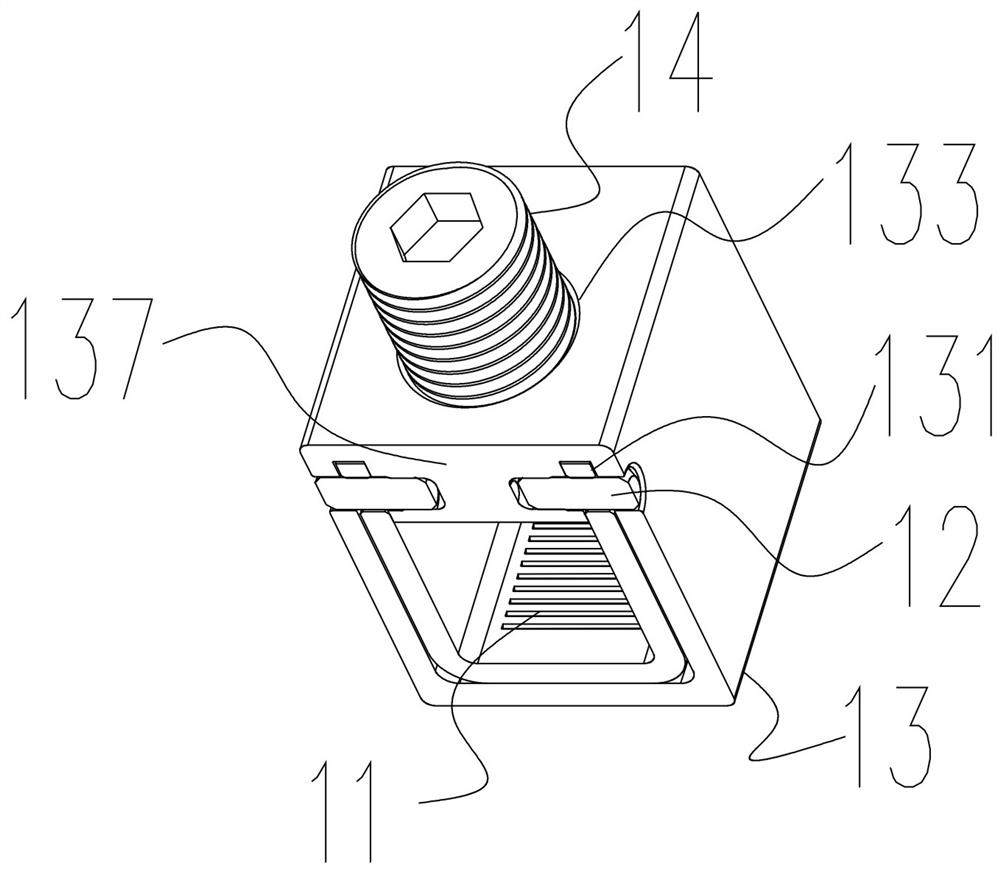

[0020] refer to figure 1 , figure 2 , image 3 , The present invention includes contacts 11 , pins 12 , square nuts 13 and screws 14 .

[0021] refer to figure 1 , Figure 4 , The contact piece 11 is provided with a "U"-shaped plug-in section 111 , and first pin holes 112 are provided on both sides of the plug-in section 111 .

[0022] refer to figure 1 , figure 2 , image 3 , Figure 5 , the square nut 13 is a rectangular cavity, the cavity is provided with orthogonal Cartesian coordinates X, Y and Z axes, and one end of the X axis is provided with a round hole 135, and a horizontal slot 136 is provided below the round hole 135, The other end is provided with a square hole, a thickened layer 137 is arranged above the square hole, and vertical slots 131 are arranged on both sides of the thickened layer 137; a second pin hole 134 is arranged on both sides along the Y axis intersecting with the vertical slot 131; One end of the Z axis located at the thickened layer 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com