A cattle slaughtering system

A technology of slaughter box and cattle body, which is applied in the field of cattle slaughter system, can solve the problems of multi-manual operation, large cattle body, and inability to complete slaughter and skinning treatment systematically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

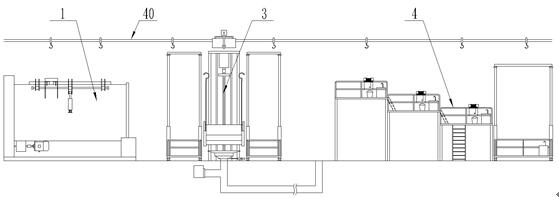

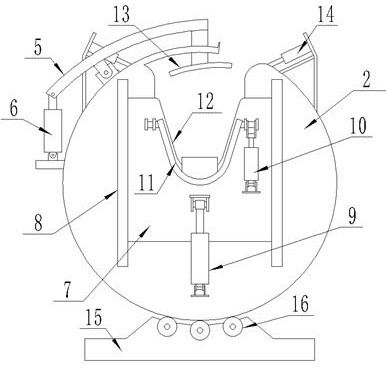

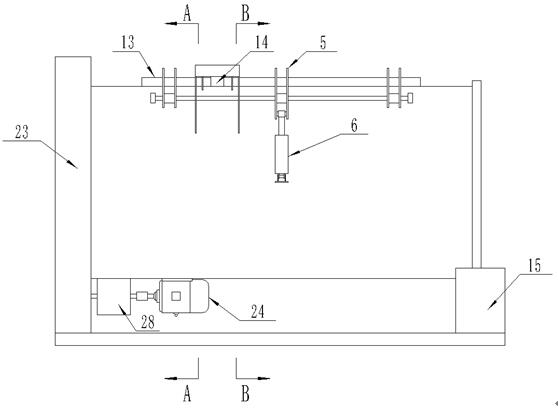

[0026] Such as Figure 1-12 As shown, the cattle slaughtering system includes a box body 2, a back pressing mechanism, a side pressing mechanism, a rear side pressing mechanism, a head pressing mechanism, and a driving mechanism. The top of the box body 2 and the rear side are openings The cylindrical structure of the box body 2 is provided with a bottom plate 19, and the front side of the box body 2 is provided with a slaughter window 18. During use, the staff drives the cattle from the passage to the box body 2, and the cattle enter through the rear opening. The portion stretches out along the slaughter window 18.

[0027] The top of the box body 2 is equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com