Ink cartridge and ink-jet printer

An ink cartridge and drop machine technology, applied in printing and other directions, can solve problems such as shell rupture, ink leakage, multiple one-way valves, and film rupture, so as to prevent ink leakage and improve printing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

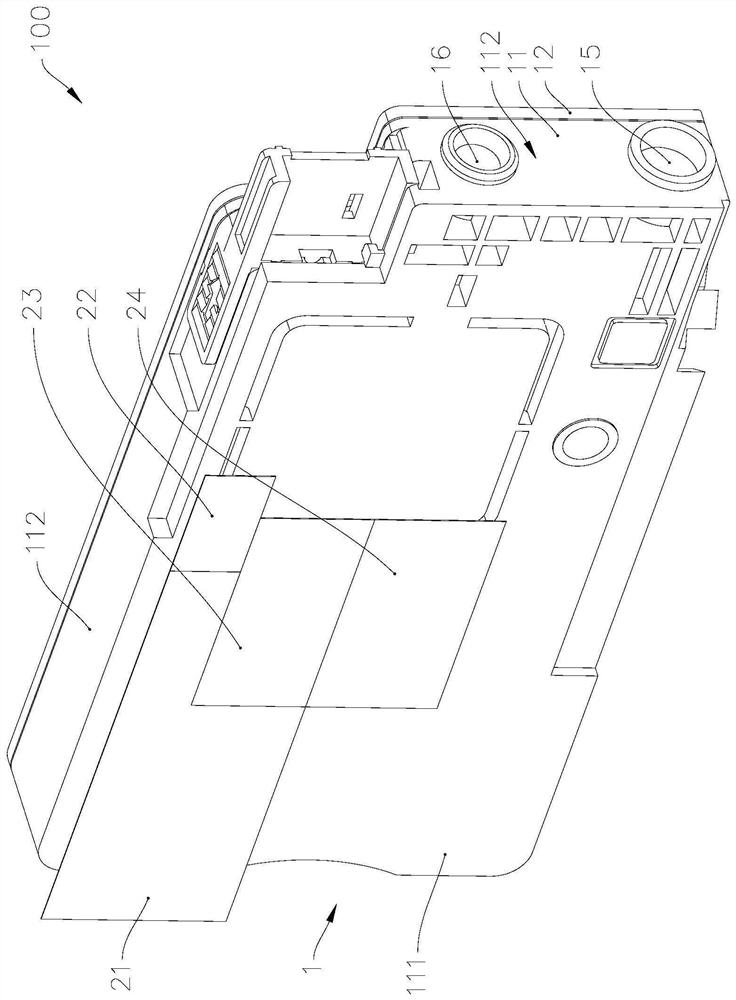

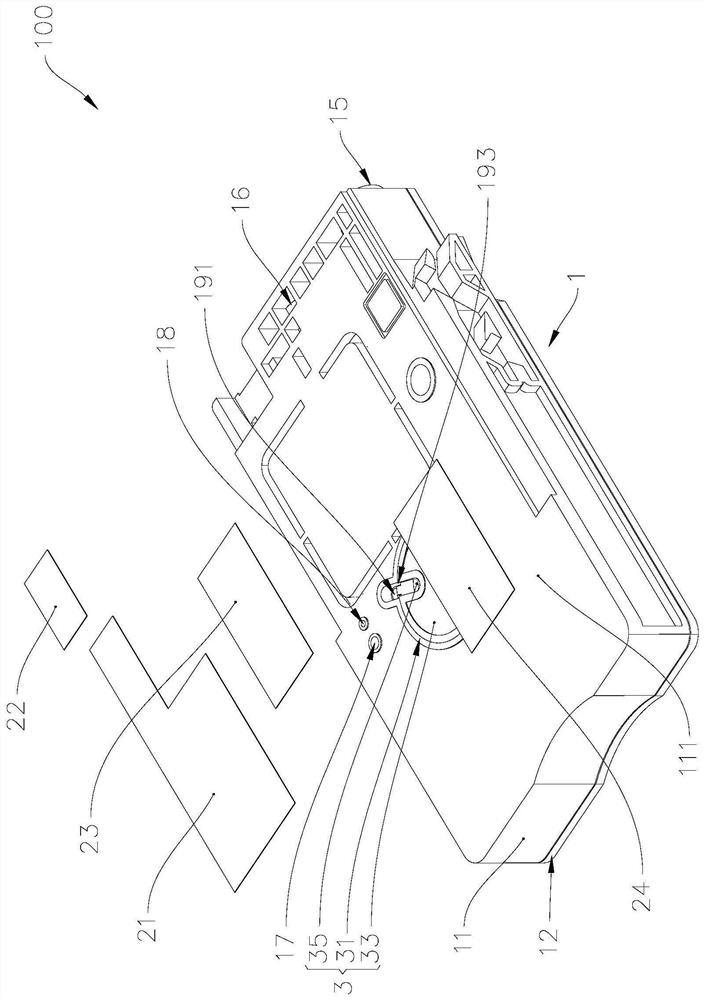

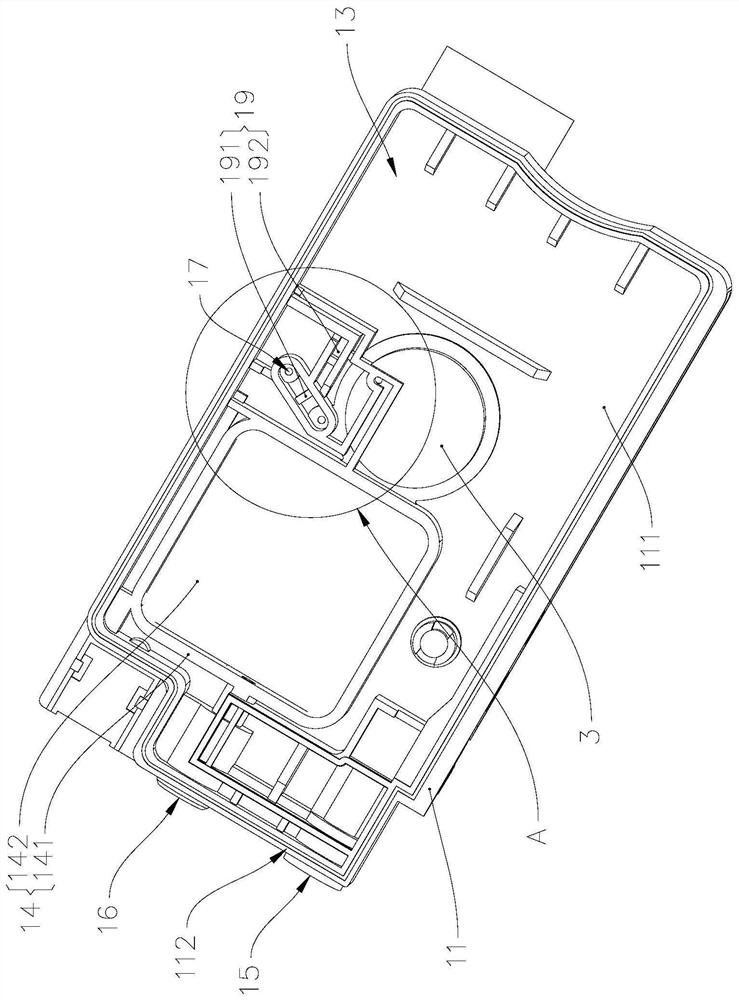

[0036] Cartridge Example:

[0037] The ink cartridge 100 is installed on the printer carriage of the printer to supply ink to the print head on the printer carriage, so that the printer carriage can print a preset printing structure on the relevant medium. refer to Figure 1 to Figure 3 , The ink cartridge 100 includes a casing 1 , a first sealing film 21 , a second sealing film 22 , a third sealing film 23 , a fourth sealing film 24 , a fifth sealing film 25 , a one-way valve 3 and a porous material 4 .

[0038] The housing 1 includes a body 11 and a cover 12. The body 11 has a receiving cavity 13 and a deformable cavity 14. The receiving cavity 13 is used for storing ink. The cover body 12 covers the opening of the receiving chamber 13 to seal the receiving chamber 13 . In addition, the cover 12 and the shell 1 can be fixedly connected by ultrasonic welding to ensure the airtightness between the cover 12 and the shell 1 .

[0039] combine Figure 4 The deformable cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com