Equipment for double-sided paint spraying of wooden door

An equipment and double-sided technology, applied in the field of equipment for double-sided painting of wooden doors, can solve problems such as prolonging the painting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

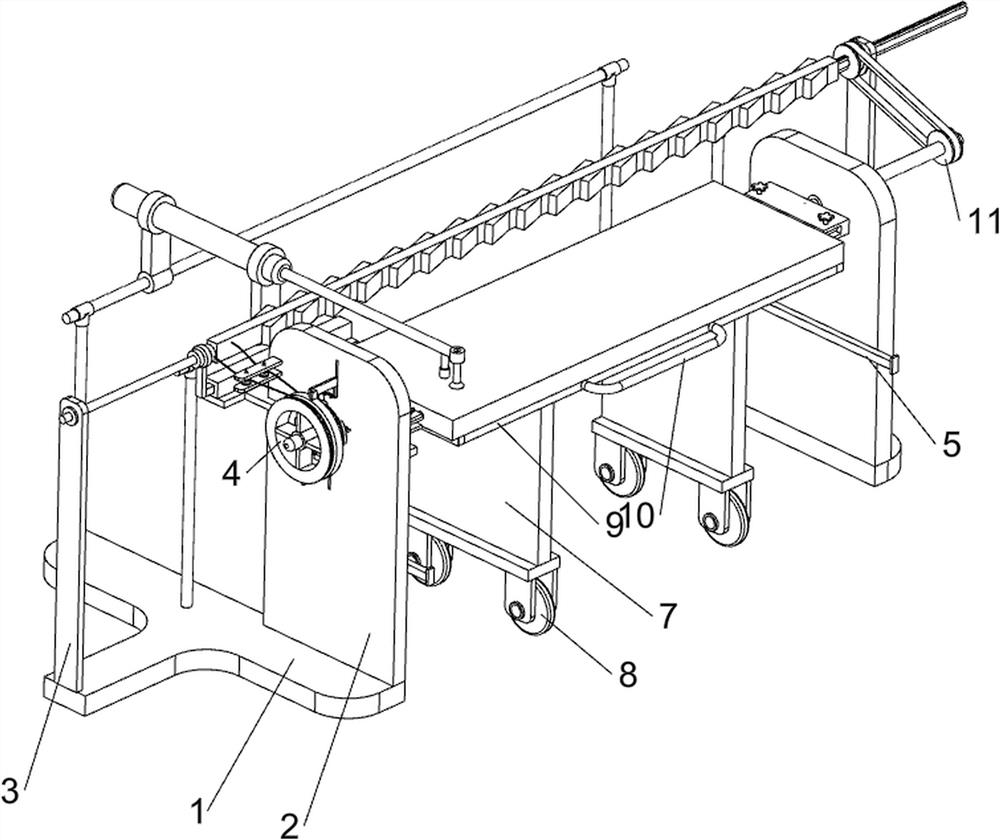

[0022] A kind of double-sided doors painting equipment, such as figure 1 Shown, comprises a bottom plate 1, the support plate 2, 3 and the moving mechanism painting rotating mechanism 4, the base plate 1 are provided on both sides of the support plate 2, the bottom plate is provided on both sides of the moving mechanism 3 Paint 1, the left 4 is provided with rotation means, spray means 3 is connected to the moving mechanism 4 rotates the second support plate.

[0023] When the user needs to be painted on both sides of doors, the equipment may be used, first, the doors need to be painted is placed in the rotation mechanism 4, and then spray painting mechanism 3 by moving the doors, after the completion of the painting side, the doors 4 by inverting the rotation mechanism, and then through three spray painting the other side moving mechanism, after painting is complete, the doors to remove the finished paint.

Embodiment 2

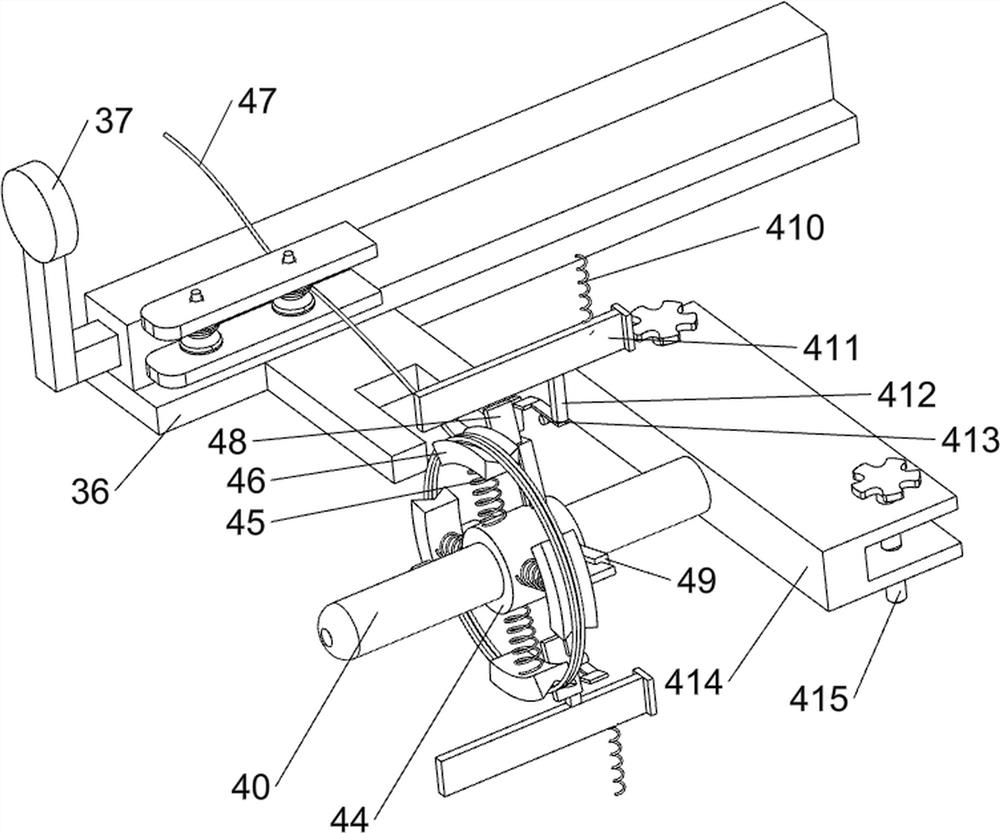

[0025] On the basis of Example 1, such as Figure 1-4 , The moving mechanism 3 includes a first painting bearing housing 30, a first shaft 31, the support frame 32, the fixed block 33, a first connecting rod 34, wedge block 35, a first connecting plate 36, an electric push rod 37, a support seat 38, cylinder 39, and the paint nozzle 310 push lever 311, the base plate 1 are provided on both sides of the first bearing block 30, on the left side of the first bearing block 30 is provided with a first movable shaft 31, the first shaft 31 has a fixed block 33, on the right side of the first bearing housing 30 is provided with a first movable connecting rod 34, a first connecting rod 34 connected to the left end of the first shaft 31, a first reverse symmetrical front and rear connecting rod 34 type provided with a plurality of uniformly spaced wedge block 35, the left rear support plate 2 is provided with a first connecting plate 36, an upper portion of the first connecting plate 36 is p...

Embodiment 3

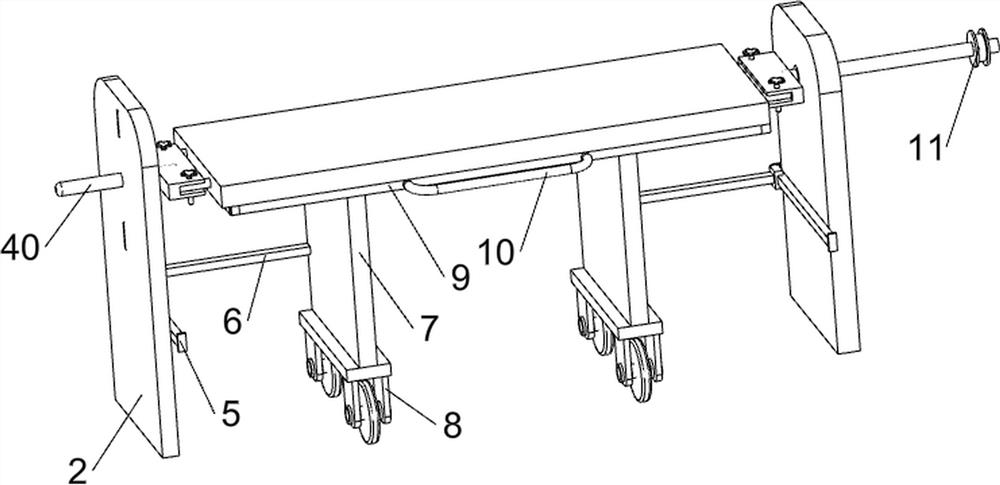

[0030] On the basis of Example 2, such as figure 1 and Figure 5 Shown, further comprising a second slide 5, slider 6, the second link plate 7, the rollers 8, 9 are placed and a handle frame 10, the inner support plate 2 the intermediate left and right sides are respectively provided with a second slide 5, 5 on the right and left sides of the second slide rail slidably provided with the slider 6, respectively, the left and right sides of the slider 6 are connected to a second connecting plate 7, left and right sides of the second connecting plate are respectively provided with a lower roller 7 8 a second connecting plate 7 is provided with an upper portion of the left and right sides of the frame 9 is disposed, is placed intermediate the front frame 9 is provided with a handle 10.

[0031] The user may be placed on the placement wooden frame 9, and by pushing the holder 9 is placed so that doors may be moved to the card plate 414, and the latch 415 through the wooden pallets and 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com