A special clamp for movable shutters and its use method

A special fixture and shutter technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of not being able to supply in time, slow speed, affecting the development of enterprises, etc., and achieve the goal of reducing operating costs, novel and unique designs, and reducing enterprise risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

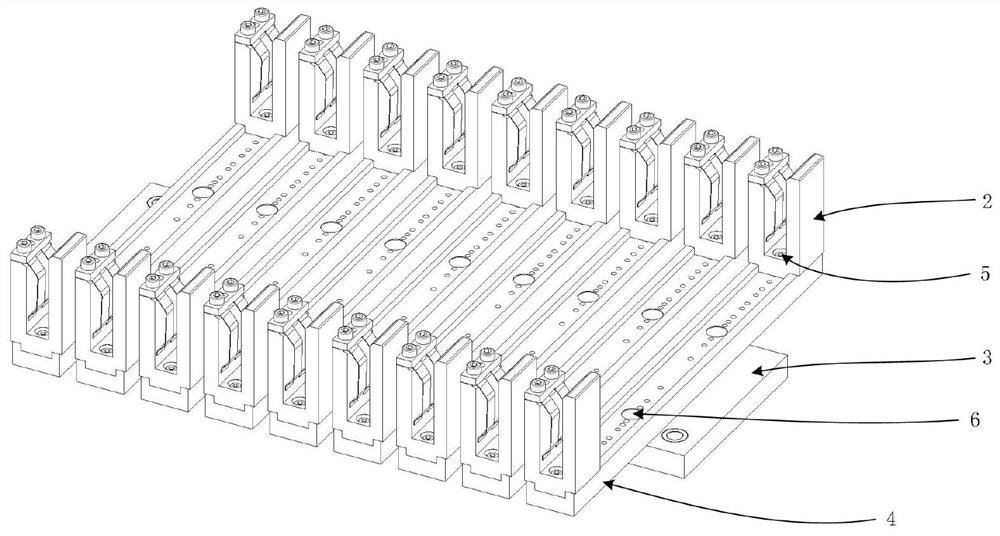

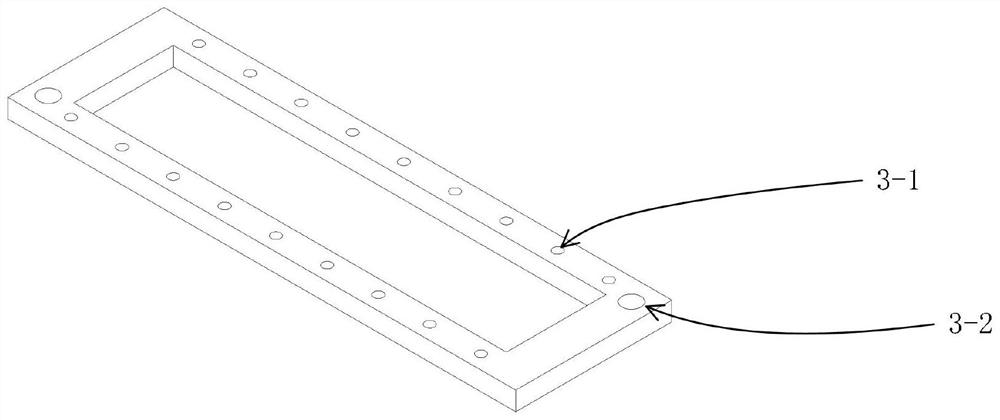

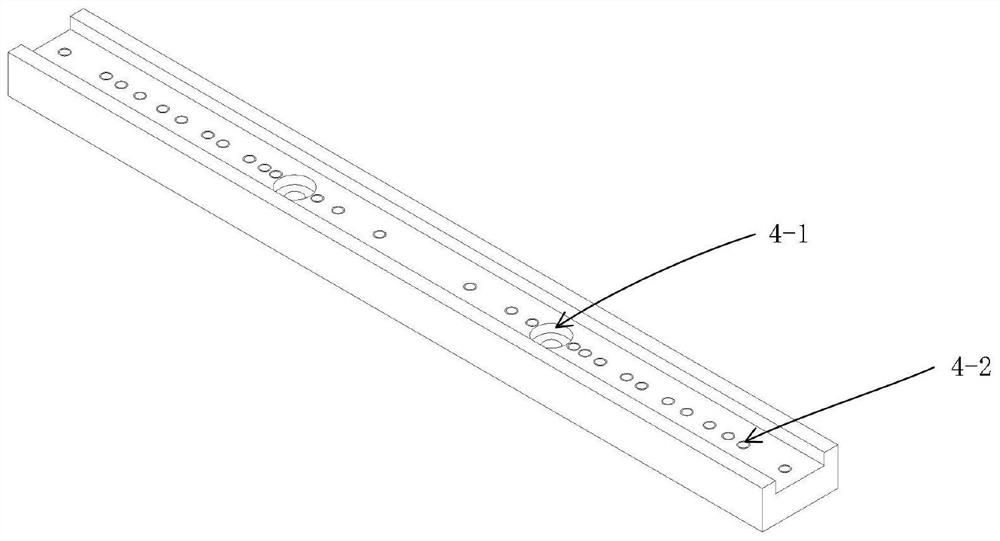

[0028] Such as Figure 1-Figure 15 Shown:

[0029] The louver comprises a movable blade 1-1, an outer frame II1-2, an outer frame I1-4 and a blade connecting rod 1-3, wherein the two sides of the movable blade 1-1 are respectively provided with an outer frame I to install mushroom heads 1-1-3 and Mount the mushroom head 1-1-2 on the connecting rod, the blade connecting rod 1-3 is provided with the blade connection installation hole I1-3-2, and the outer frame I1-4 is provided with the blade connection installation hole II1-4-2 and the outer frame II is connected to the installation guide bar 1-4-3, and the outer frame II1-2 is provided with the outer frame I connection guide groove 1-2-2 and the outer frame I connection card seat 1-2-3, and the movable blade 1-1 is engaged In the middle of the blade connection rod 1-3, the blade connection installation hole I1-3-2 and the connection rod installation mushroom head 1-1-2 are snapped together, and the blade connection installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com