A method to improve the efficiency of sorting and dispensing medicine process

A technology of efficiency and process, applied in the field of automatic drug delivery, can solve the problems of long drug delivery process and low drug delivery efficiency, so as to improve the efficiency of drug delivery, reduce the time of drug delivery, and reduce the effect of binding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

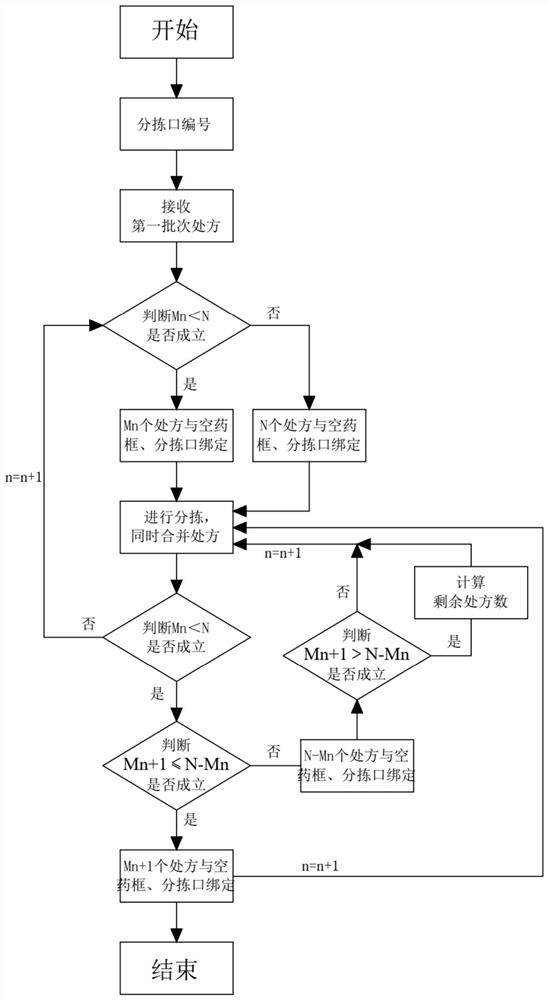

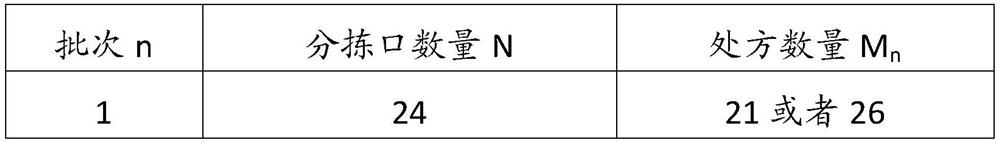

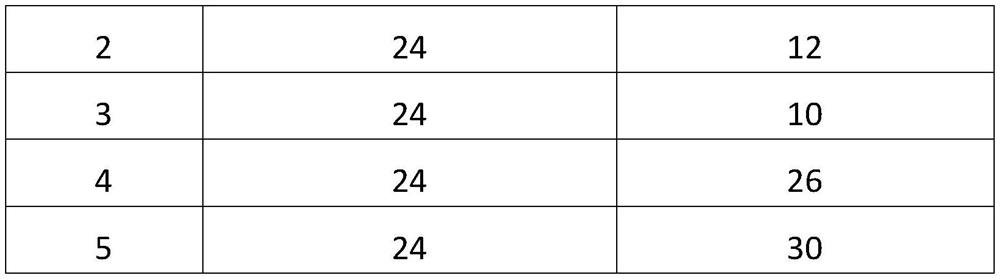

[0021] Below in conjunction with accompanying drawing, the utility model is described in detail.

[0022] like figure 1 A method for improving the efficiency of the sorting and dispensing process is shown, the method is:

[0023] S1. Number the sorting ports of the sorting machine in sequence. There are N sorting ports, and the numbers are numbered from the farthest sorting port of the sorting machine from small to large, that is, the numbers are 1, 2, 3... ··N, the farthest sorting port is the sorting port closest to the exit of the sorter. If there are multiple sorting ports at the same distance from the exit of the sorter, these sorting ports will be randomly numbered according to the numbering sequence.

[0024] S2. Receive the first batch of prescriptions, the number of prescriptions is M 1 indivual.

[0025] S3. Judging M n n prescriptions fully bound, the M n One-to-one correspondence between prescriptions and M n sorting port for binding, M n The sorting ports a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com