Chili seed and peel separation device

A separation device, the technology of chili seeds, applied in the field of chili processing, can solve the problems of irritating odor, worker injury, cut finger, operation error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

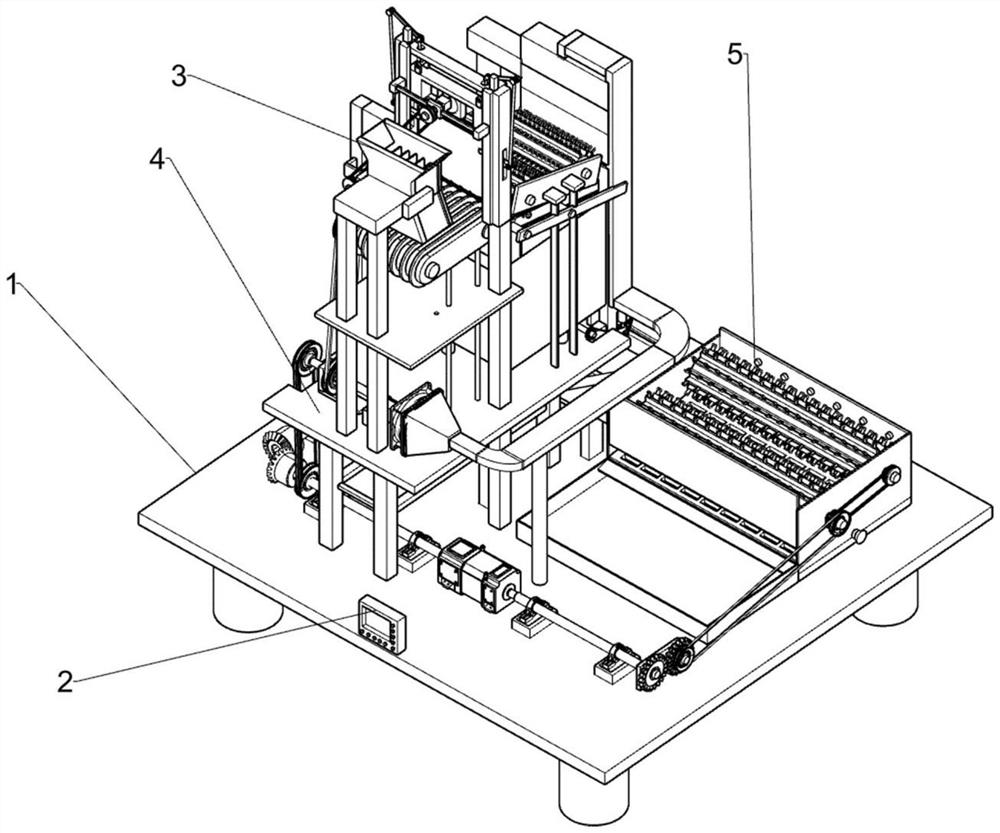

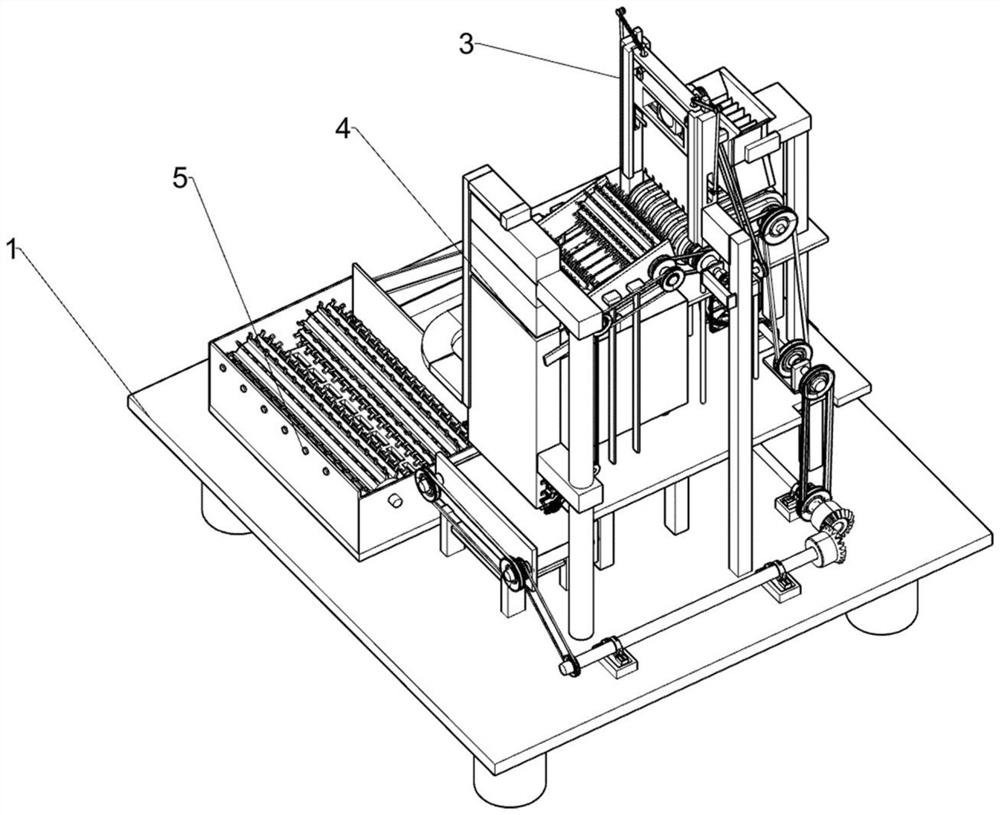

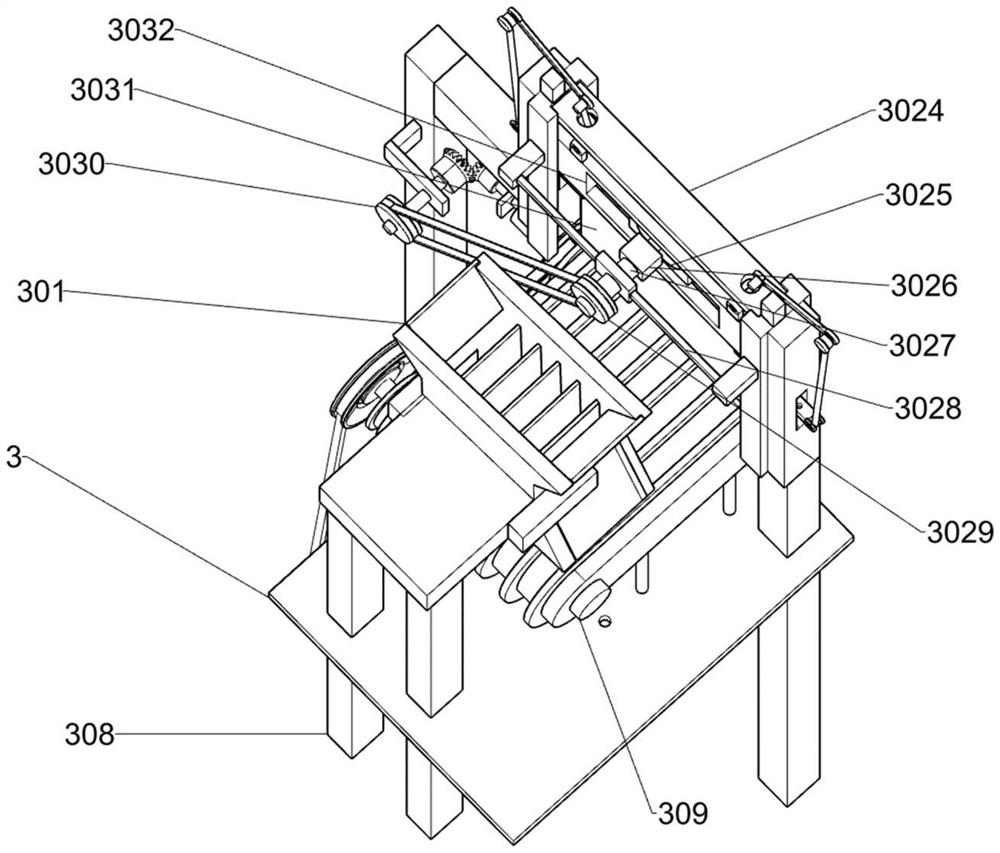

[0032] A kind of capsicum seed skin separating device, as Figure 1-11 As shown, it includes a chassis 1, a controller 2, a section cutting mechanism 3, a separation mechanism 4 and a cleaning mechanism 5; a controller 2 is arranged above the chassis 1; the chassis 1 is connected with the section cutting mechanism 3; the chassis 1 The upper part is welded with the separation mechanism 4; the upper part of the bottom frame 1 is connected with the cleaning mechanism 5; the section cutting mechanism 3 is connected with the separation mechanism 4; the separation mechanism 4 is connected with the cleaning mechanism 5.

[0033] Before the equipment works, the equipment chassis 1 is installed on a stable working place, and the section cutting mechanism 3 is connected to the peripheral pepper conveying device, so that the peppers enter the equipment to complete the follow-up work; the cleaning mechanism 5 is connected with a water pipe to clean the pepper skins; Then turn on the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com