Garbage unloading system

A technology for garbage and unloading hoppers, which is applied in the direction of garbage cans, garbage collection, loose filter material filters, etc. It can solve the problems of increasing the workload of incinerators, poor drainage of garbage pits, and easy blockage of the bottom of garbage pits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

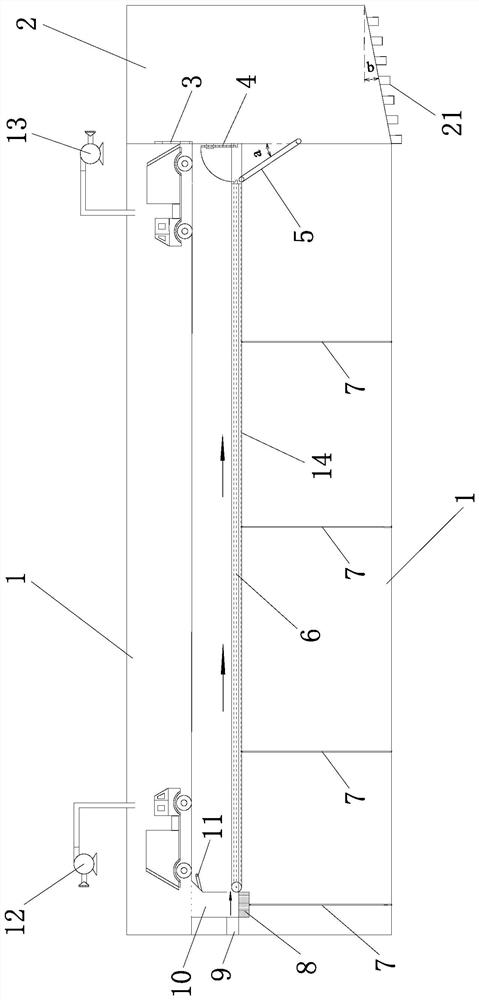

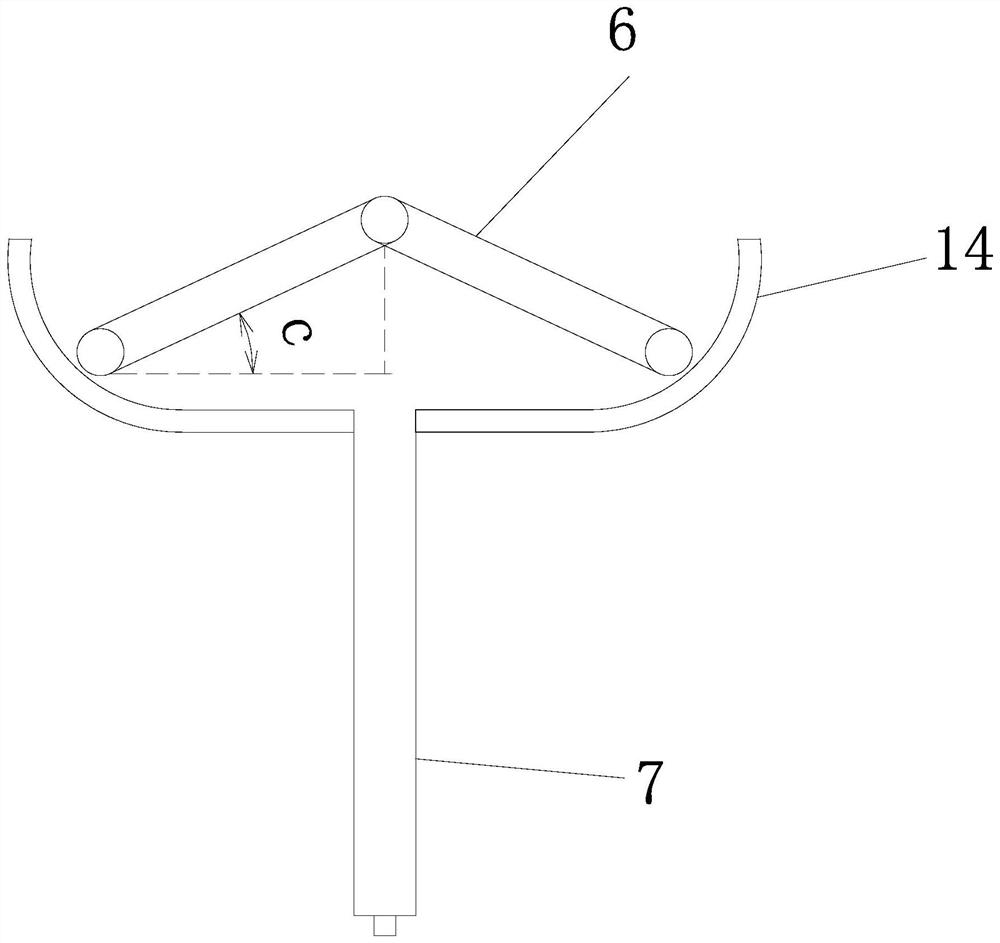

[0025] Such as figure 1 with figure 2 As shown, the garbage unloading system of the present invention includes an unloading platform 1, and the inside of the unloading platform 1 includes upper and lower layers. The garbage truck travels on the upper layer of the unloading platform 1 and dumps garbage. The top of the unloading platform 1 is provided with a ventilation assembly. The opposite sides of the unloading platform 1 are respectively provided with a discharge hopper 10 and a closed garbage pit 2. The garbage pit 2 and the unloading hopper 10 are connected by a transmission assembly. The transmission assembly is arranged on the lower floor of the unloading platform 1. There are filter assemblies 8 . The garbage truck pours the garbage into the discharge hopper 10, and the solid-liquid separation of the garbage is carried out through the filter assembly 8. The leachate flows into the leachate collection system (not shown in the figure), and the solid waste is transporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com