Anti-seepage nut and opposite-pull screw assembly

A technology that pulls the screw and prevents water seepage. It is applied in the on-site preparation of building components, the connectors of formwork/formwork/work frame, and construction. It can solve problems such as loss, construction waste, and influence on decoration effects. Low cost, no construction waste, easy to manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

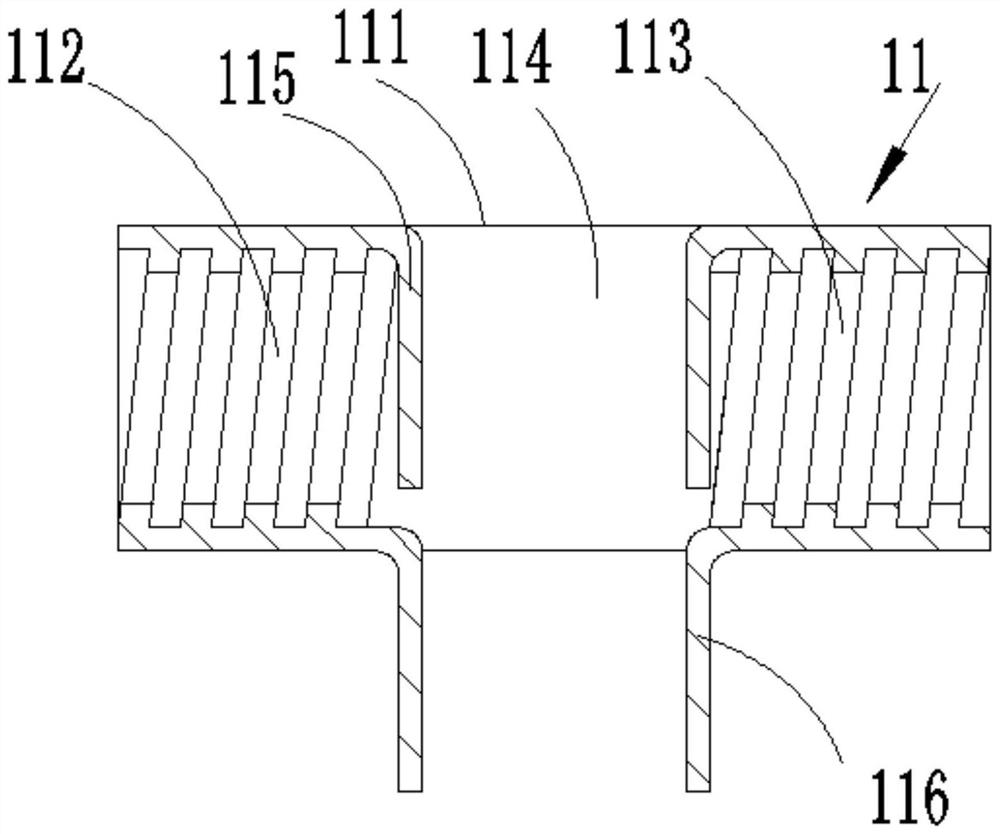

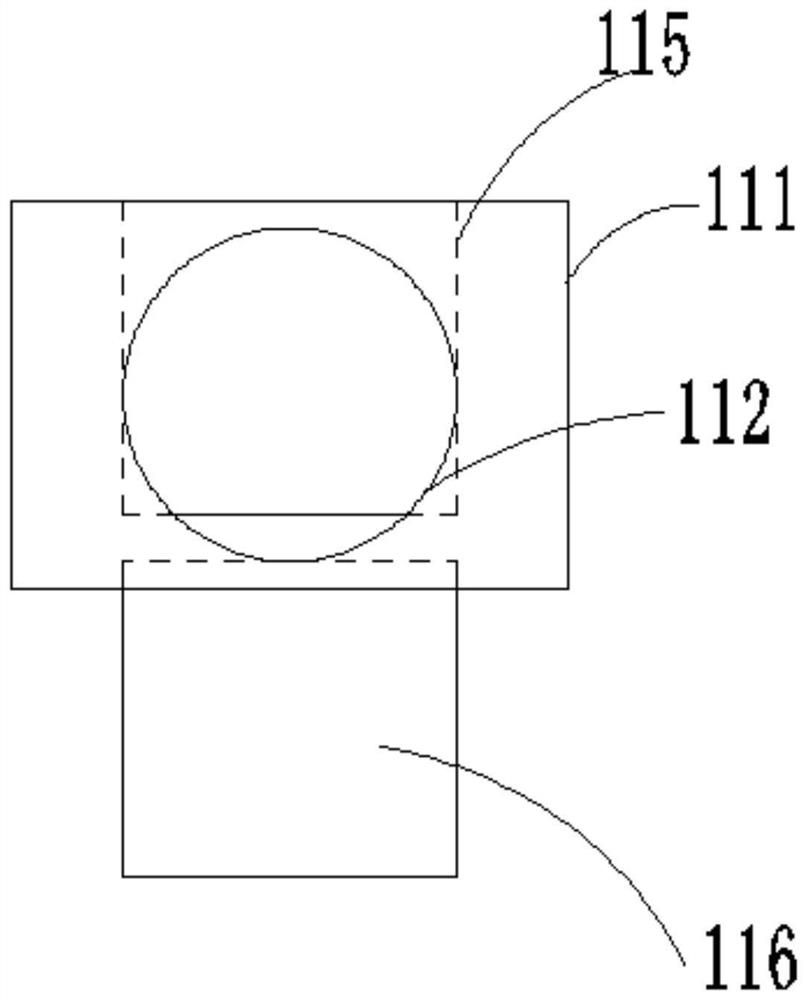

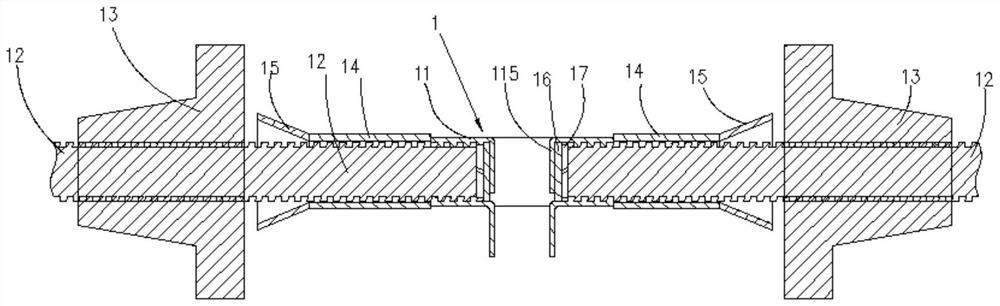

[0050] like figure 1 , 2 As shown, the anti-seepage nut 11 provided in this embodiment includes a body 111, a first connecting portion 112 with internal threads provided at one end of the body 111, and a first connecting portion 112 with internal threads provided at the other end of the body 111. The second connection part 113; the body 111 has at least one anti-seepage hole 114 arranged radially between the first connection part 112 and the second connection part 113; the first connection part 112 and the anti-seepage Internal barrier structures 115 are provided between the holes 114 and between the second connecting portion 113 and the anti-seepage hole 114 . When there are two or more anti-seepage holes 114, they are arranged side by side in sequence along the axial direction.

[0051] The above-mentioned radial direction refers to the cross-sectional direction of the anti-seepage nut, and the axial direction refers to the length direction of the anti-seepage nut.

[0052]...

Embodiment 2

[0060] like Figure 7 , 8 As shown, the first embodiment is repeated, the difference is that in this embodiment, the inner blocking structure 115 includes a first baffle 1151 and a second baffle 1152 oppositely arranged, and the first baffle 1151 and the second baffle The second baffle 1152 is a split structure, so that the inner barrier structure 115 partially isolates the anti-seepage hole 114 from the first connection portion 112 , and the anti-seepage hole 114 from the second connection portion 113 .

[0061] In this embodiment, the anti-seepage nut is located at the end side of the pull screw assembly, and the sleeve is only installed at one end of the anti-seepage nut, finally forming a Figure 9 Concrete wall panel construction shown.

Embodiment 3

[0063] like Figure 10 , 11 As shown, the first embodiment is repeated, the difference is that in this embodiment, the inner barrier structure 115 completely isolates the seepage-proof hole 114 from the first connecting portion 112, and separates the seepage-proof hole 114 from the first connection portion 112. The two connection parts 113 are completely isolated.

[0064] In this embodiment, the installation structure of the pull screw assembly and the concrete formwork installed with the anti-seepage nut is the same as that of Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com