Rigid body mark point optimization method and device and optical motion capture system

An optimization method and a technology of marking points, applied in the field of motion capture, can solve problems such as inaccurate rigid body matching, instability, and unstable rigid body posture, so as to improve motion capture accuracy, reduce the probability of problems, and inaccurate or inaccurate rigid body matching The effect of steady improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

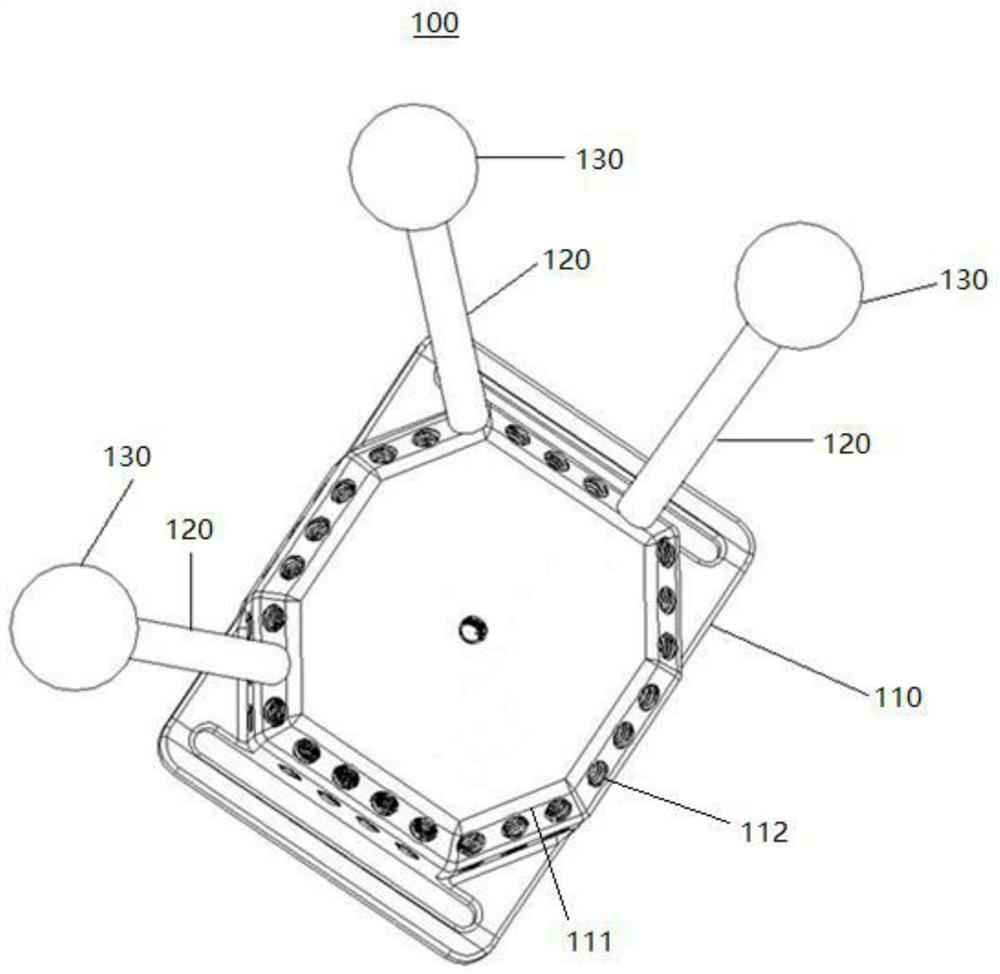

[0042] Please refer to figure 1 , the present application discloses a structural diagram of a rigid body. The rigid body structure 100 includes: a rigid body base 110, a threaded surface 111, a threaded slot 112, a support rod 120, a marking point 130, etc., and a plurality of threaded surfaces 111 are provided on the rigid body base 110. and a plurality of threaded slots 112 , the plurality of threaded slots 112 are distributed on the plurality of threaded surfaces 111 , the support rod 120 is inserted into the threaded slots 112 , and the marking point 130 is located at the top of the support rod 120 .

[0043] The rigid base 110 may be in any shape, that is, the rigid base 110 may be a cube, a cuboid, a cylinder or other shapes, which are not specifically limited here. The size of the threaded surface 111 can be set according to the actual situation. Generally, 1-16 threaded surfaces 111 are set on the rigid body base 110 to distribute a certain number of threaded slots 112...

Embodiment 2

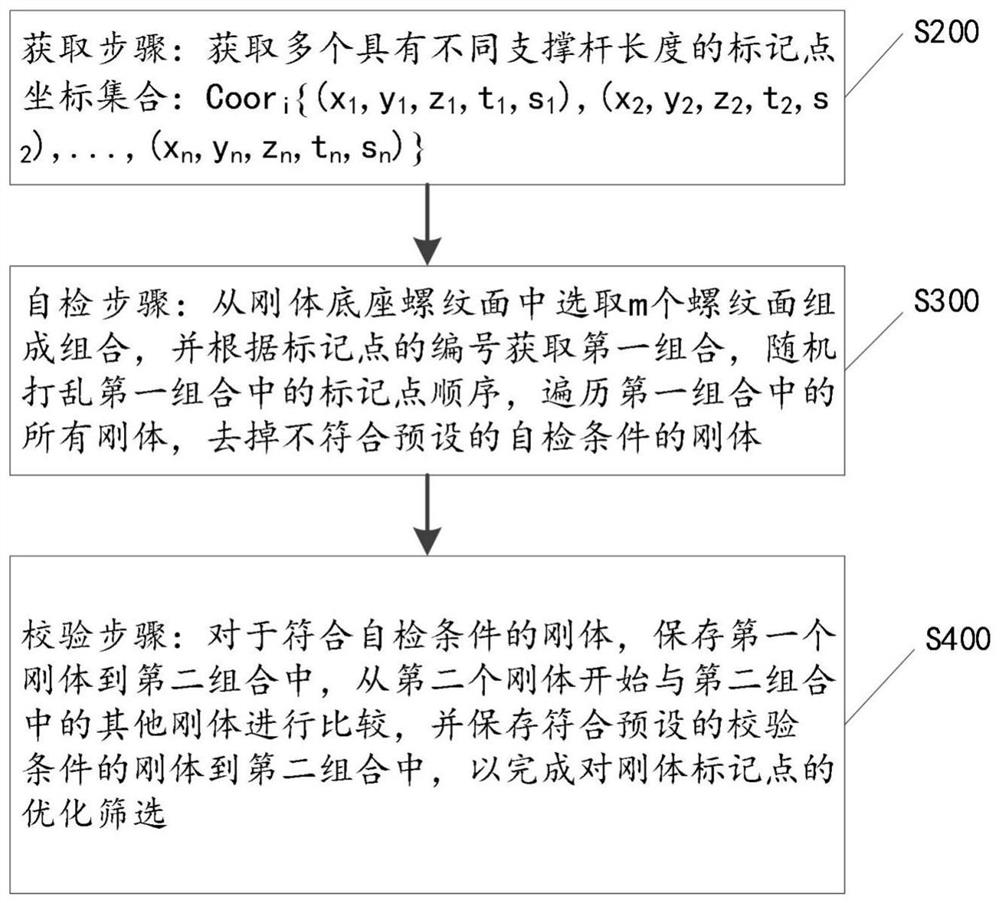

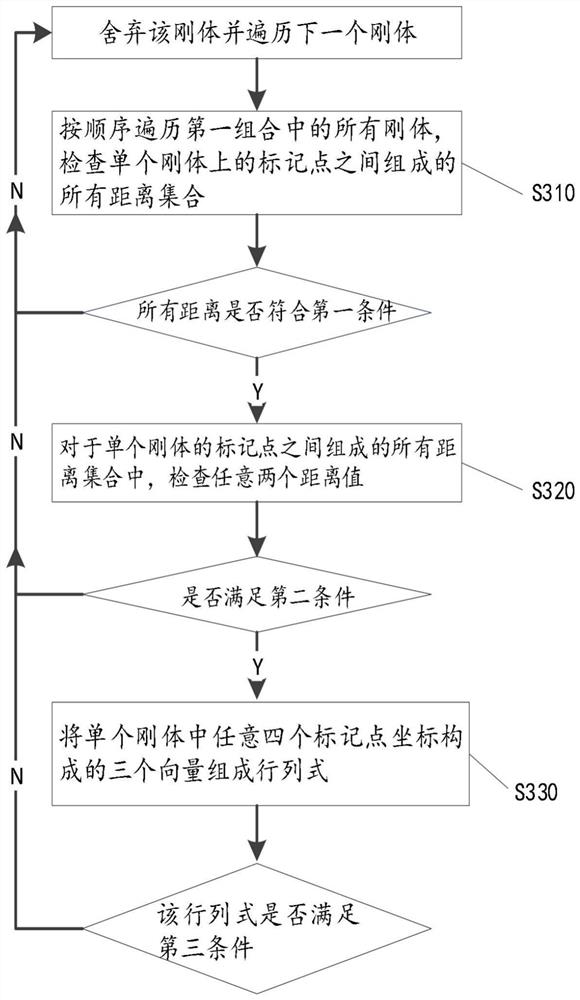

[0048] Please refer to figure 2 , after understanding figure 1 On the basis of the rigid body structure shown, this embodiment discloses a method of how to optimize the rigid body marking points. The method claimed includes steps S200-S500, which will be described separately below.

[0049] Step S200, obtaining step: obtaining a plurality of coordinate sets of marker points with different lengths of support rods: Coor i {(x 1 ,y 1 ,z 1 , t 1 ,s 1 ), (x 2 ,y 2 ,z 2 , t 2 ,s 2 ),..., (x n ,y n ,z n , t n ,s n )}, wherein, x, y, z represent three-dimensional coordinate values, i=1, 2, ..., a, represent the number of marking points, n=1, 2, ..., b, represent the number of threaded slots of the rigid body base , t ∈ {1, 2, ..., a} represents the number of the corresponding support rods with different lengths, and s ∈ {1, 2, ..., c} represents the number of the threaded surface of the rigid body base.

[0050] In an embodiment, this step S200 may include: obtaining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com