Wedged pin

A wedge and pin technology, applied in the direction of pins, connecting components, mechanical equipment, etc., can solve the problem of time-consuming, and achieve the effect of increasing the adjustability and simplifying the installation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

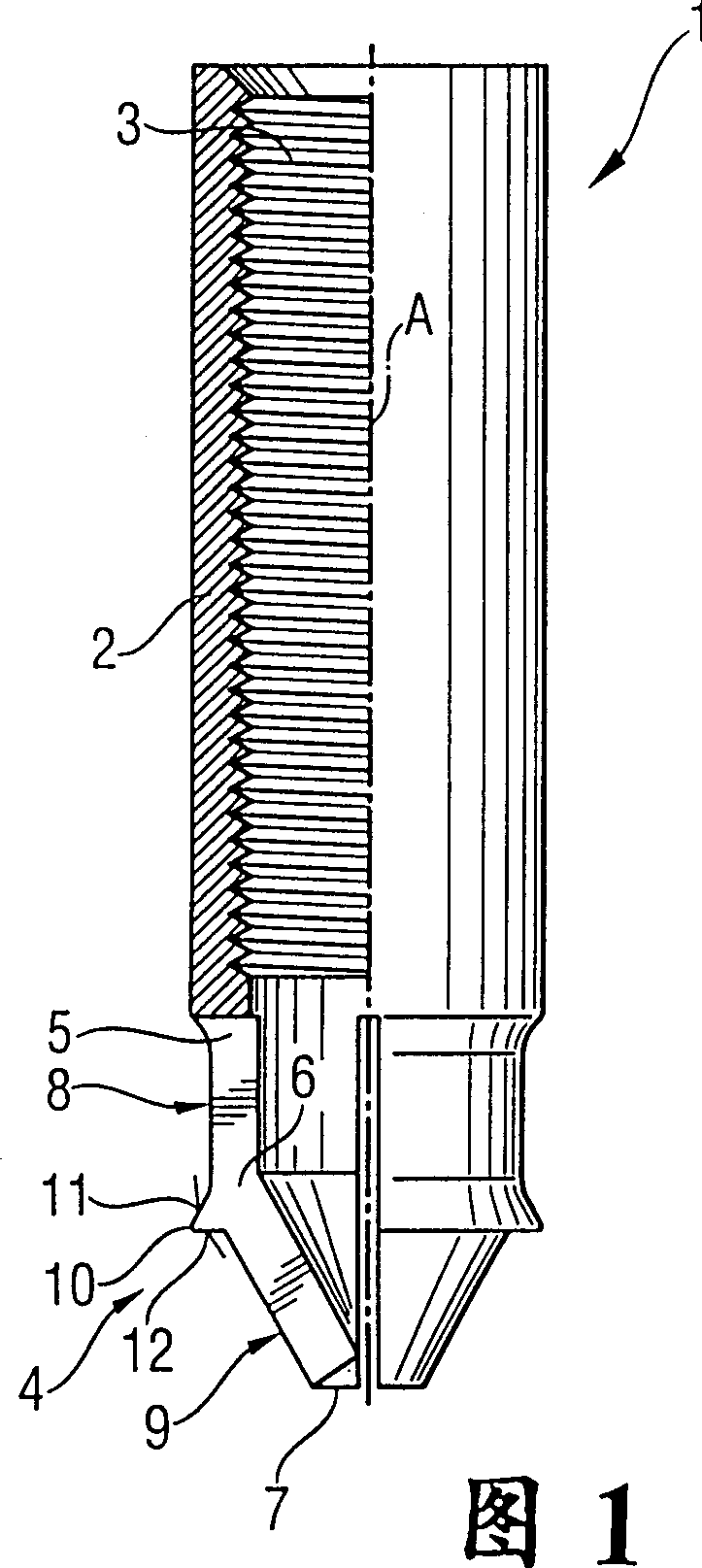

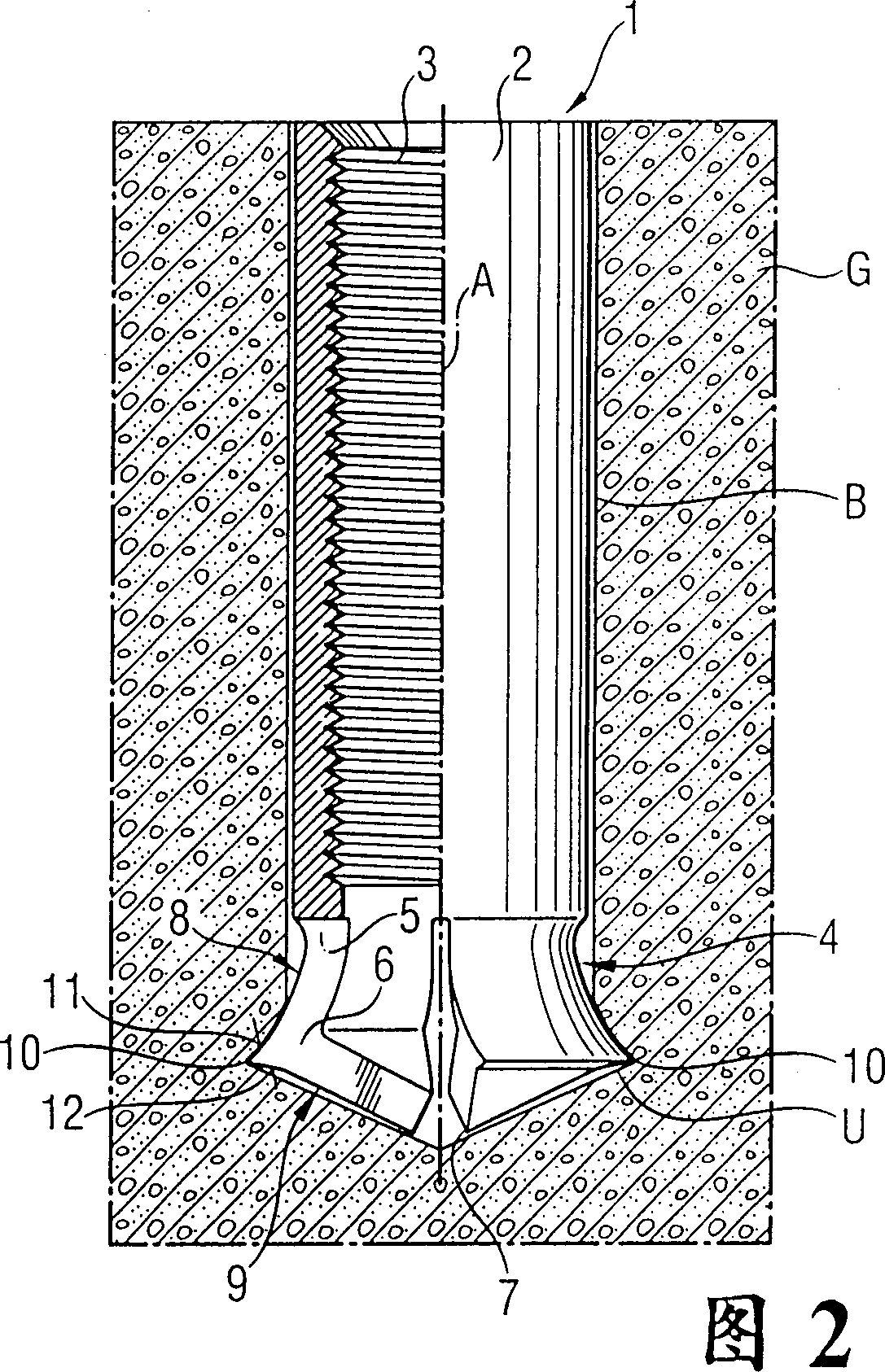

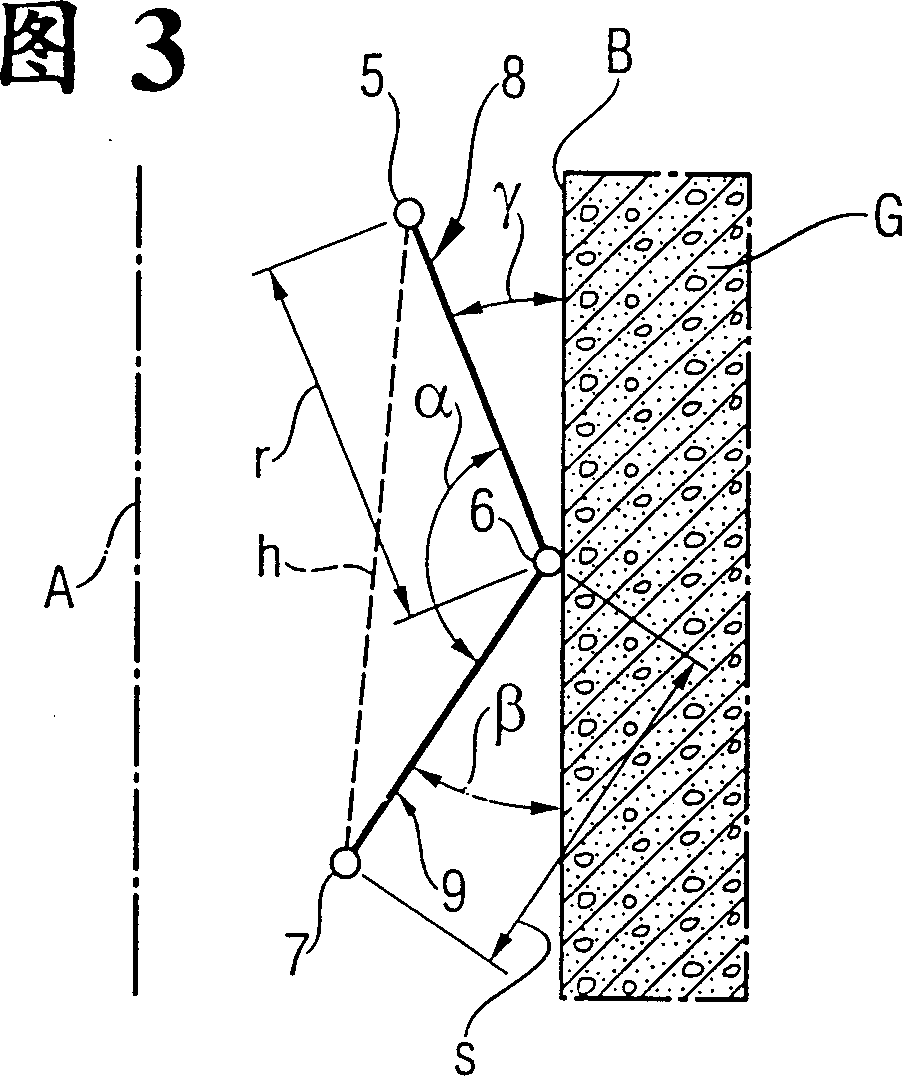

[0023] A first exemplary embodiment of a wedging pin according to the invention is generally designated by the symbol 1 in FIGS. 1 and 2 . It consists of a metal sleeve 2 provided with an internal thread 3, which has expansion arms on its front section 4, which are separated from each other by axial grooves. The expansion arm is connected to the sleeve 2 via an articulating transition zone, preferably a plastic joint 5, and has a flexible joint 6, by which the expansion arm is divided into a rear expansion arm 8 and a front expansion arm 9 . The front expansion arm 9 is distributed obliquely relative to the rear expansion arm 8 . The front end 7 of the front expansion arm 9 simultaneously constitutes the front end of the sheath 2 and is closer to the axis A of the sheath 2 than the plastic joint 5 .

[0024]As shown in FIG. 3 , the two spreading arms 8 , 9 form an angle of approximately 100° to 160°. The angle between the outer surface of the front expansion arm 9 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com