Railway vehicle body with pivotable panels

A rail vehicle and main body technology, which is applied in the field of rail vehicles, can solve problems such as unsightly clearance, noise leakage, and complex structure of rail vehicles, and achieve the effect of reducing the risk of vandalism and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

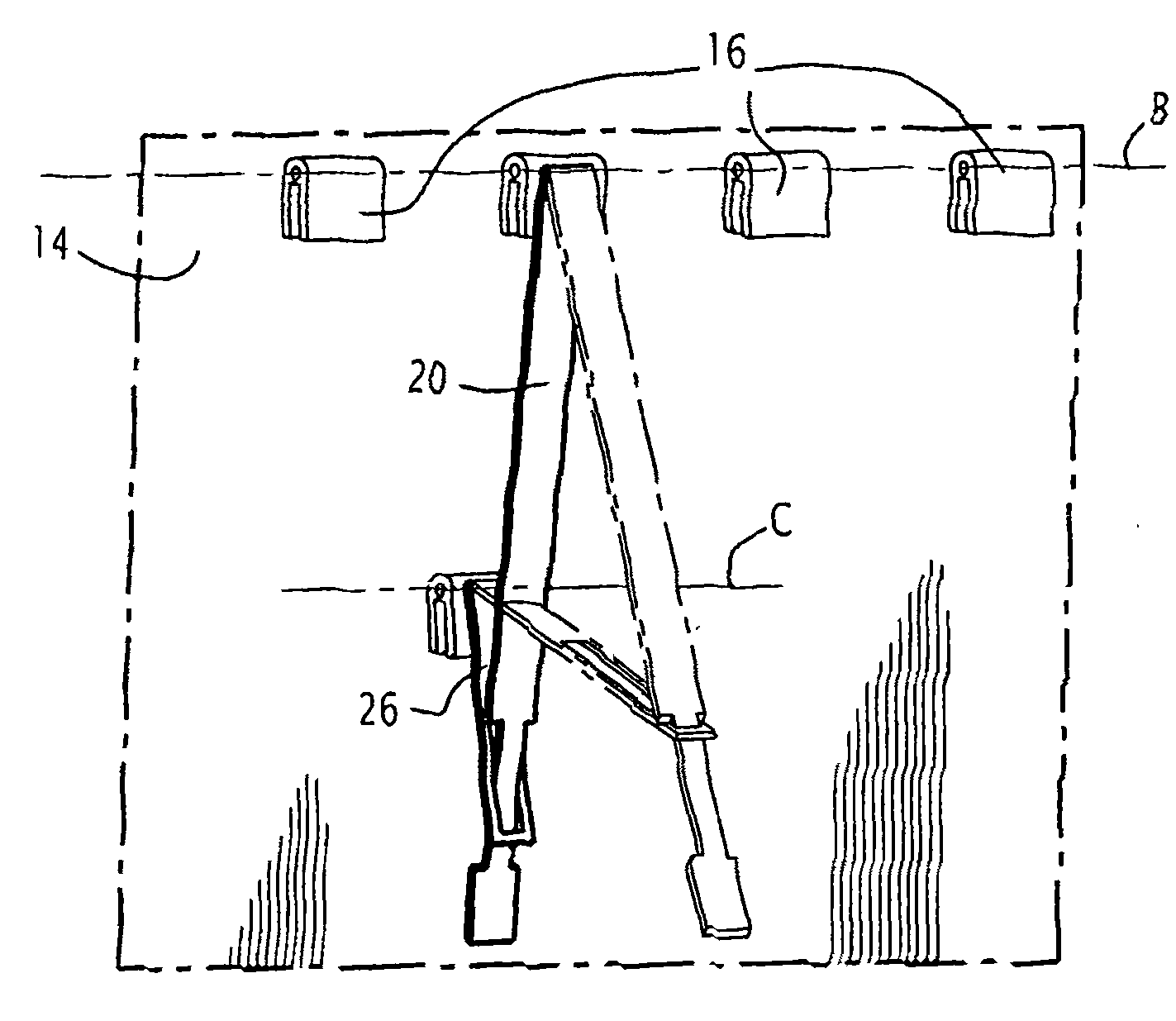

[0024] In this description, the term "longitudinal" is defined as the direction in which the body of the rail vehicle extends corresponding to its width, and the term "transverse" is defined as the direction substantially perpendicular to said longitudinal direction and corresponding to the width of the body.

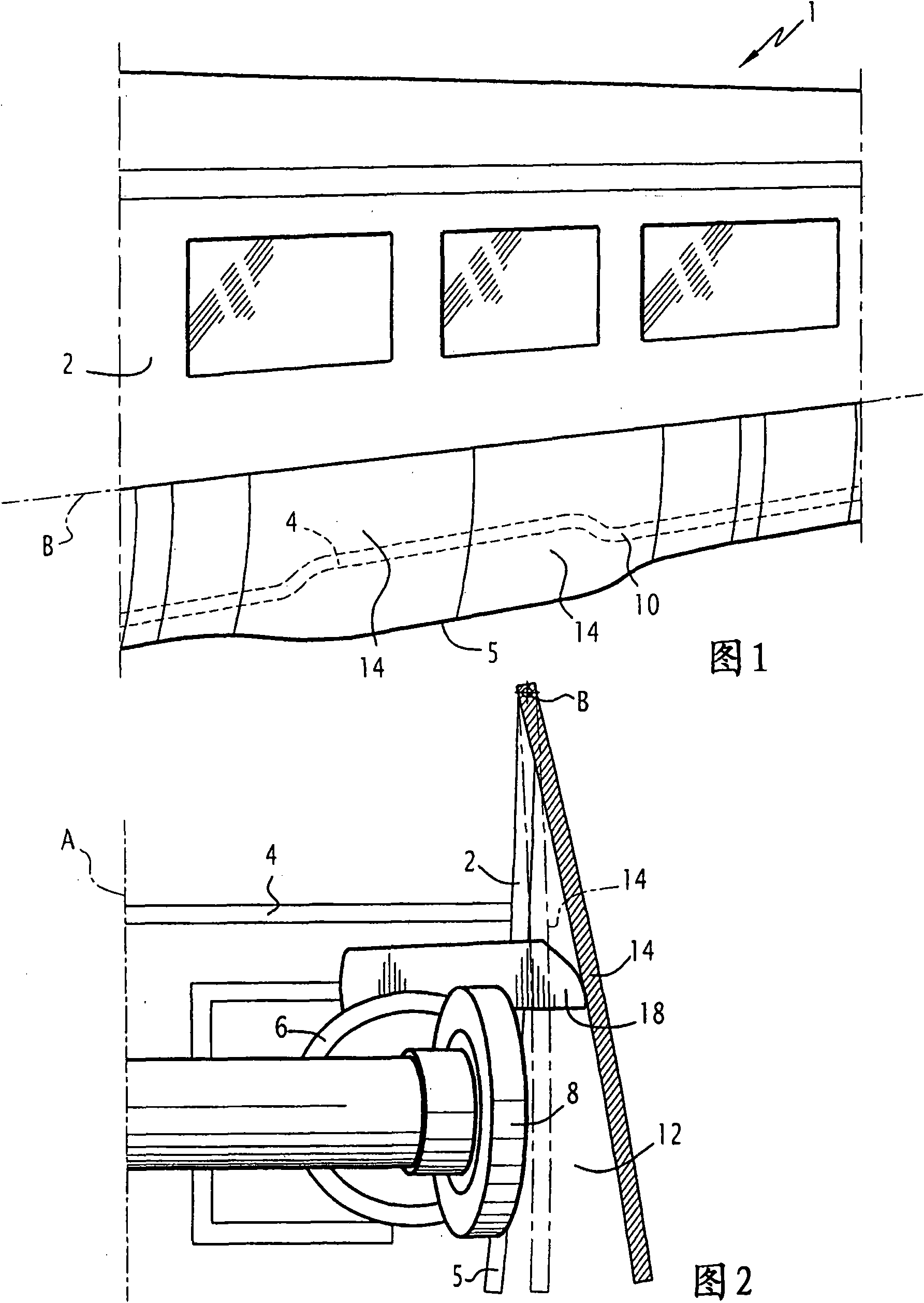

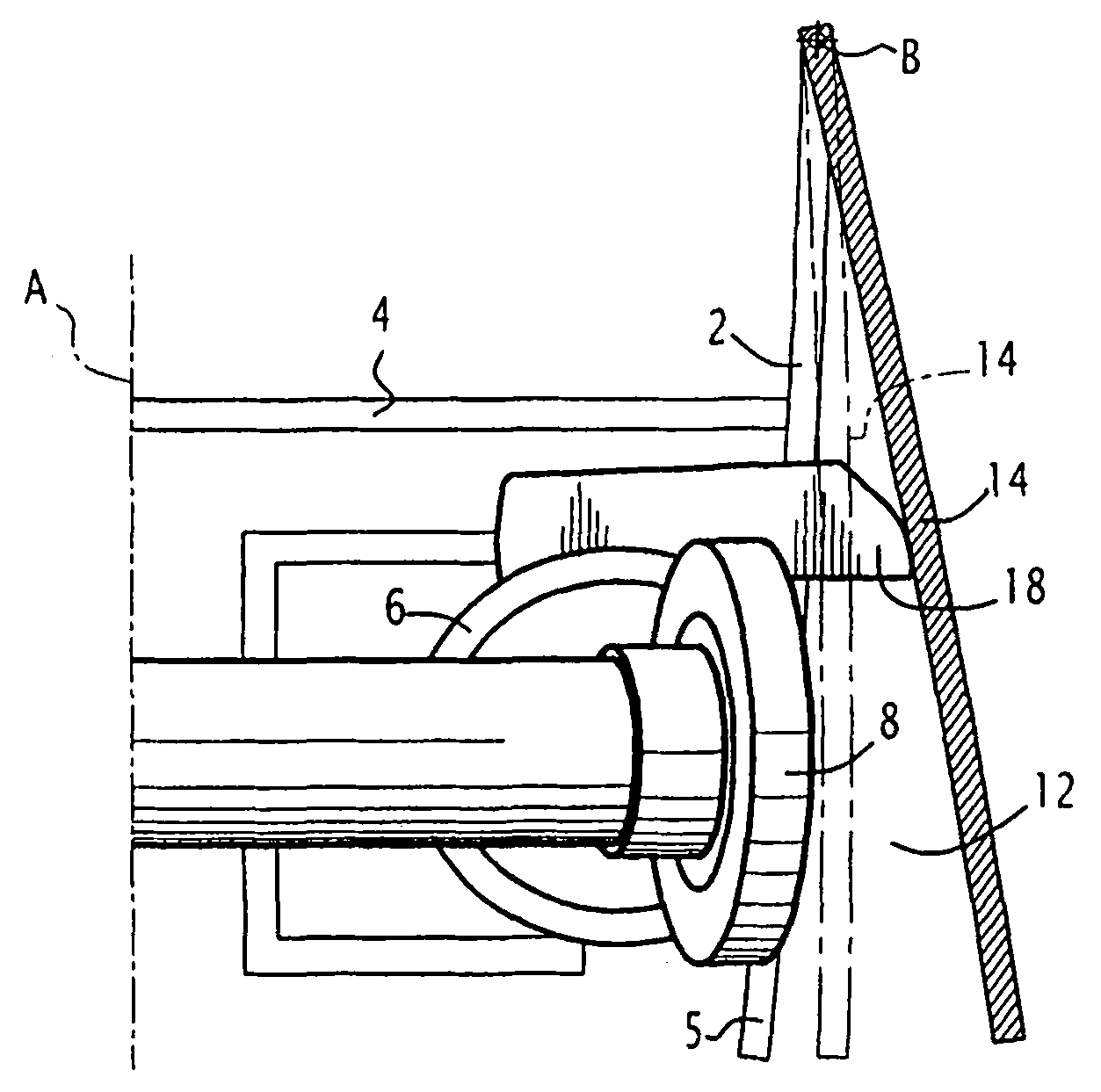

[0025] refer to figure 1 , shows a rail vehicle body 1 of the trolley type, for example, having two longitudinal walls 2 (only one of which is shown in the figure) extending over the entire length of the body extend parallel to each other, and are arranged at one side and the other side of the bottom plate 4 (such as figure 1 The two longitudinal walls 2 are fixedly joined to the bottom plate 4 .

[0026] Some parts of the equipment of the rail vehicle are mounted below the floor 4 and said longitudinal wall 2 is arranged to extend opposite these parts of the equipment in order to conceal them. Thus, each wall 2 comprises a portion 5 extending below the floor, at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com