Permanent magnet eddy-current loss calculation method for fractional-slot four-layer winding permanent magnet motor

A permanent magnet motor, eddy current loss technology, applied in complex mathematical operations, design optimization/simulation, special data processing applications, etc., can solve the problems of complex four-layer winding structure and difficult to establish analytical models, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

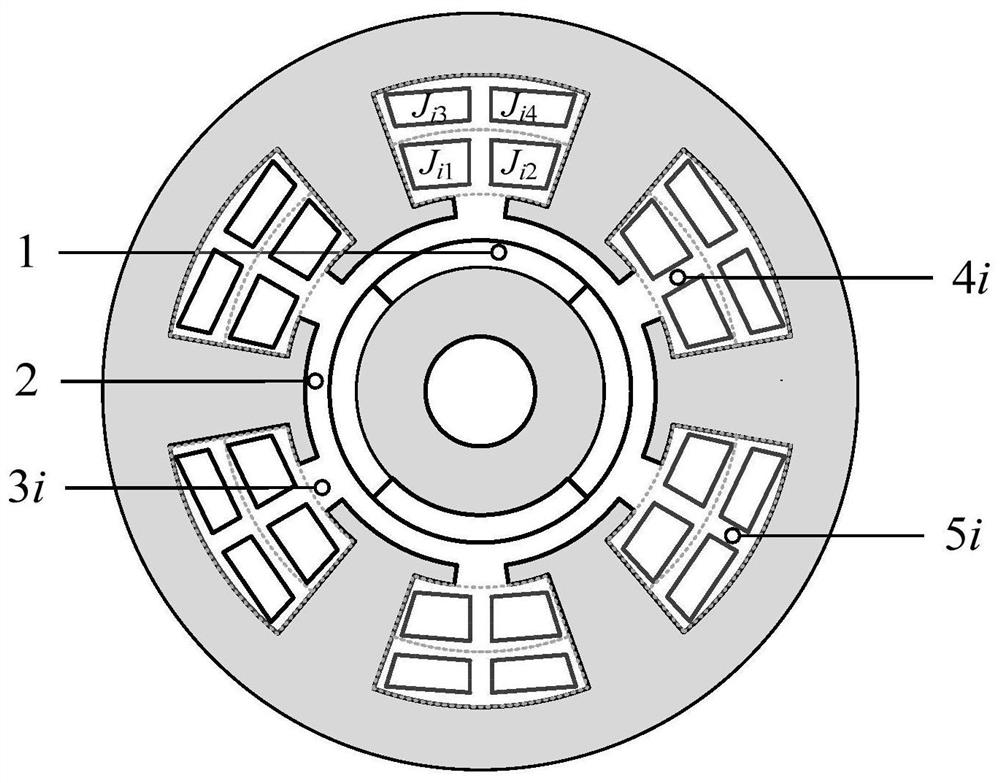

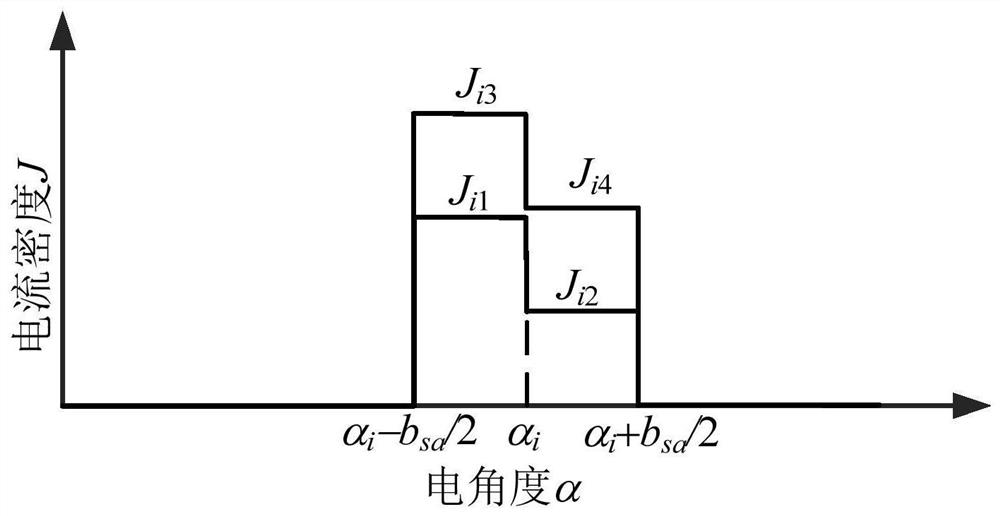

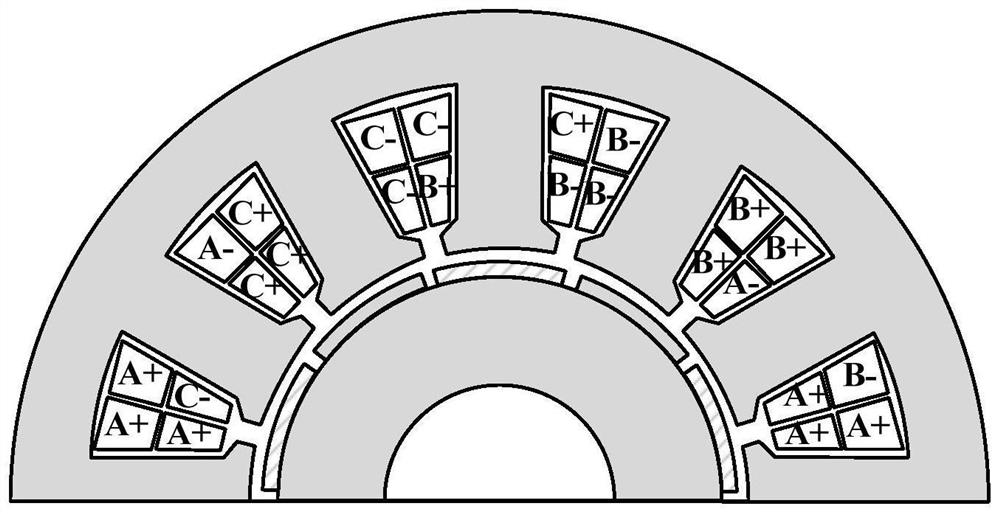

[0205] like image 3 As shown, it is a surface-mounted permanent magnet motor with 10 poles, 12 slots, fractional slots, and four-layer windings. image 3 Among them, A, B and C are the phase sequence of the three-phase armature winding, and the symbols "+" and "-" indicate the reference direction of the armature current. The basic parameters of the motor are shown in Table 1. Taking this motor as an example, the method of the present invention is used to solve and calculate the armature reaction field distribution and permanent magnet eddy current loss of the fractional slot four-layer winding surface-mounted permanent magnet motor.

[0206] Table 1 Basic parameters of permanent magnet motor

[0207]

[0208]

[0209] The motor area is divided into five sub-areas: permanent magnet area 1, air gap area 2, stator notch area 3i, upper winding area 4i on the slot body and lower winding area 5i on the slot body, i=1,2,3,... .,Q, Q is the number of motor slots.

[0210] De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com