Edible sunflower grain lifter, edible sunflower picking frame and edible sunflower picking table

A technology of a grain supporter and a picking table, which is applied in the field of sunflower picking, can solve the problems of not being able to adapt to the characteristics of sunflower planting, achieve the effects of stabilizing the integrity of the sunflower plate, preventing seed splashing, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

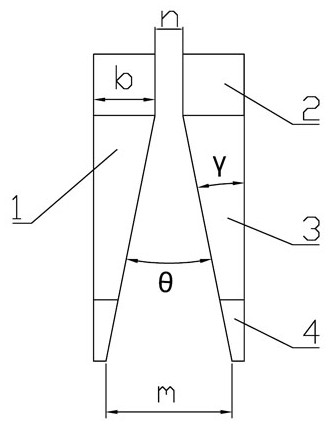

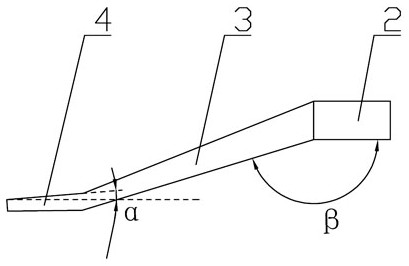

[0028] Embodiment one: as attached figure 1 , 2 As shown, the sunflower-eating grain raising device includes a left grain raising device 1 and a right grain raising device that are distributed at intervals from left to right, and the left grain raising device 1 includes a first fixing part and a first connecting part that are fixedly installed together from back to front. And the first entrance part, the first connecting part is inclined in the shape of low front and high rear, and the front is narrow and the rear is wide. The width of the first fixed part is the width b of the grain lifter, and the width b of the grain lifter is between 80mm and 120mm. The angle between the upper side of the entrance part and the horizontal plane is the first included angle α, the first included angle α is between 4° and 6°, the included angle between the lower side of the first fixing portion and the lower side of the first connecting portion is the second included angle Angle β, the second...

Embodiment 2

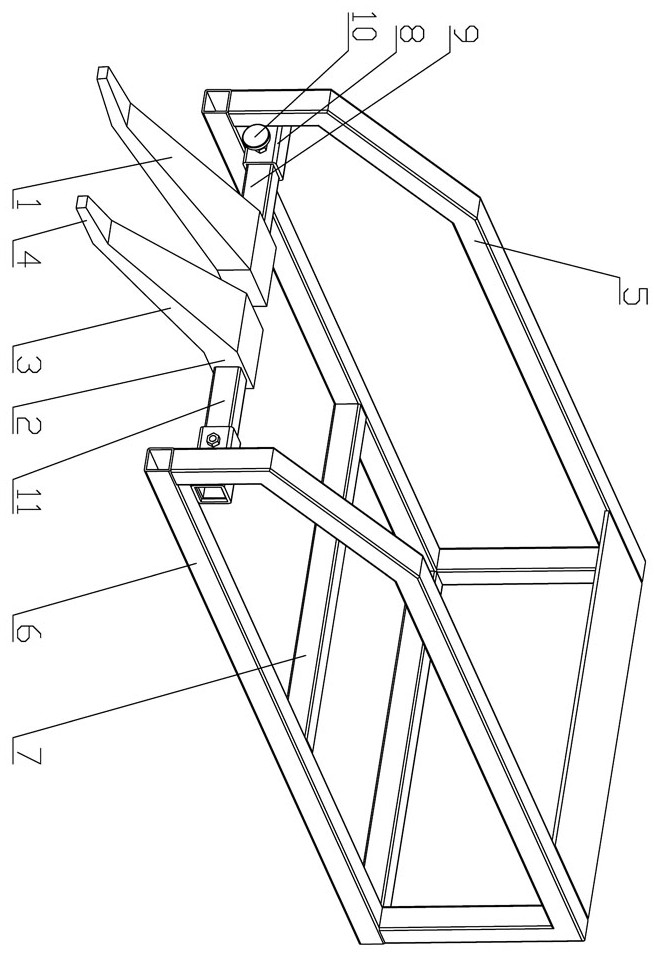

[0031] Embodiment two: as attached figure 1 , 2 , shown in 3, the sunflower picking rack that uses the above-mentioned sunflower-eating and grain-supporting device includes left side frame 5, right side frame 6, crossbeam 7, left mounting column, right mounting column 11 and sunflower-eating grain-supporting device, left side frame 5 and the right side frame 6 are distributed at intervals from left to right, and a crossbeam 7 is fixedly installed between the left side frame 5 bottom and the right side frame 6 bottom, and the left side frame 5 front end rear side is fixedly installed with a left mounting column whose right end is located on its right side. The right end of the mounting column is fixedly installed together with the left side of the first fixed part, and the rear side of the front end of the right side frame 6 is fixedly installed with a right mounting column 11 whose left end is located on its left, and the left end of the right mounting column 11 is fixed to th...

Embodiment 3

[0034] Embodiment three: as attached figure 1 , 2 , 3, 4, and 5 show that the sunflower picking platform that uses the above-mentioned sunflower support frame includes power shaft 12, driving device, left fixed roller, right fixed roller, feed box 19, fixed column 18, left underframe, Left side plate, left conveyer belt 14, right underframe, right side plate, right conveyer belt 16 and check pin 17, power shaft 12 outside left and right intervals are provided with at least one edible sunflower picking frame, are positioned at the left side frame 5 middle parts of leftmost position Fixedly install the fixed column 18, the rear side of the fixed column 18 is provided with a first shaft seat, the left end of the power shaft 12 is installed in the first shaft seat, and the right end of the power shaft 12 is located on the right side of the right side frame 6 at the rightmost position of the seat. 12 The right end is connected with the driving device through transmission; the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com