An anti-broken needle device of a calibration instrument

A technology of anti-breakage and calibration instrument, applied in the direction of measuring tube/pipette, etc., can solve the problems of high operator requirements, increased use cost, broken needle accidents, etc., to reduce use cost, provide use safety, and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

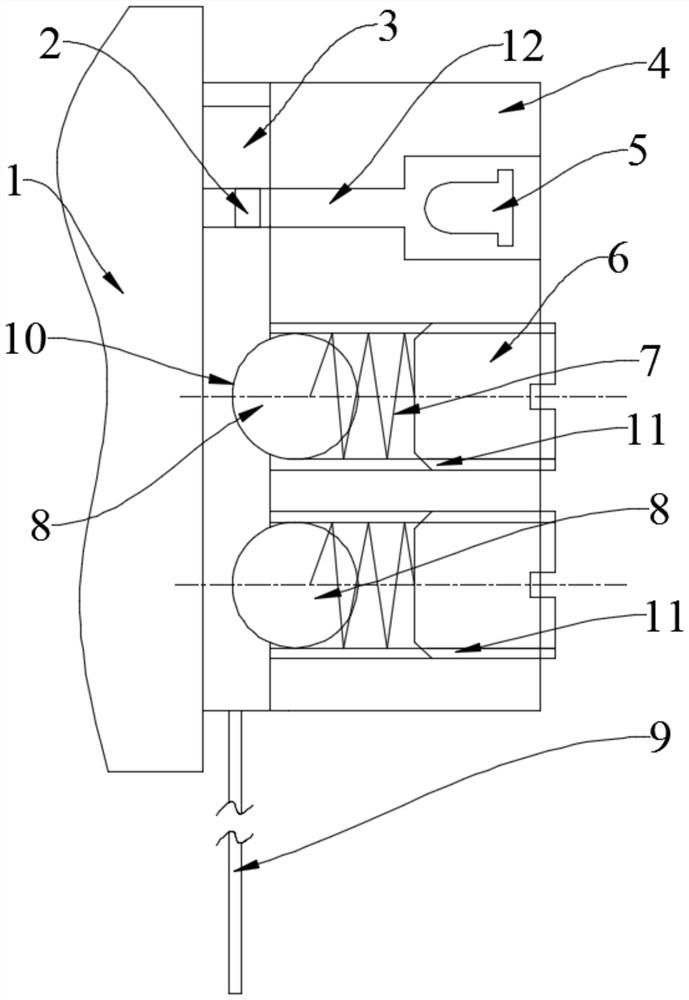

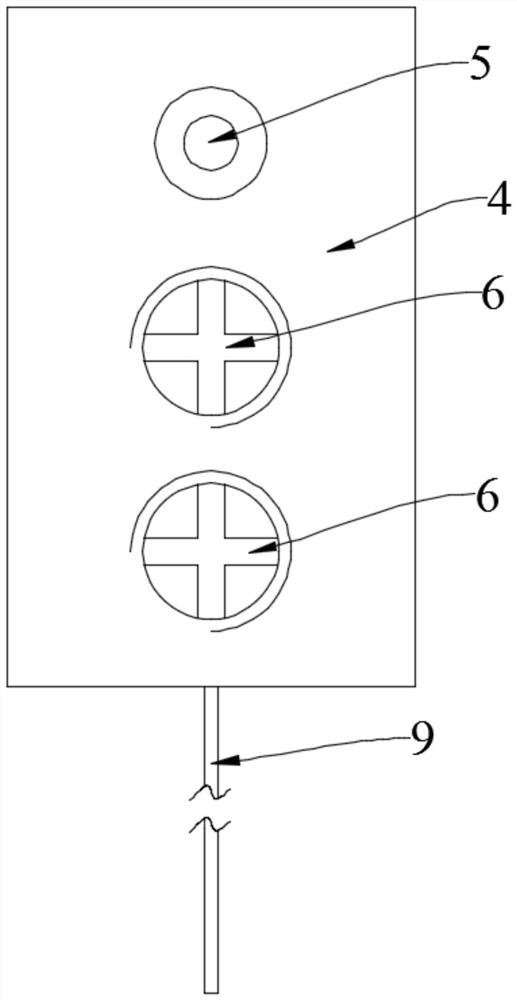

[0024] Example 1, such as figure 1 and figure 2 As shown, the present invention provides an anti-broken needle device for a standard matching instrument, which includes a base 1, a fixed plate 4, a slider 3, a pipetting needle 9, a position detection device and a flexible positioning device. The moving parts of the standard instrument are connected, the fixed plate 4 is installed on the base 1, and a slideway for the slider 3 to slide up and down is provided between the fixed plate 4 and the base 1, and the slider 3 is installed in the slideway. The pipetting needle 9 is fixed on the lower part of the slider 3 and protrudes from the lower end of the slideway. The flexible positioning device is used to apply a lateral contact force to the slider 3 so that the position of the slider 3 is fixed in the slideway. The position detection device is used to detect whether the position of the slider 3 in the slideway deviates and sends a control signal to the control system of the cal...

Embodiment 2

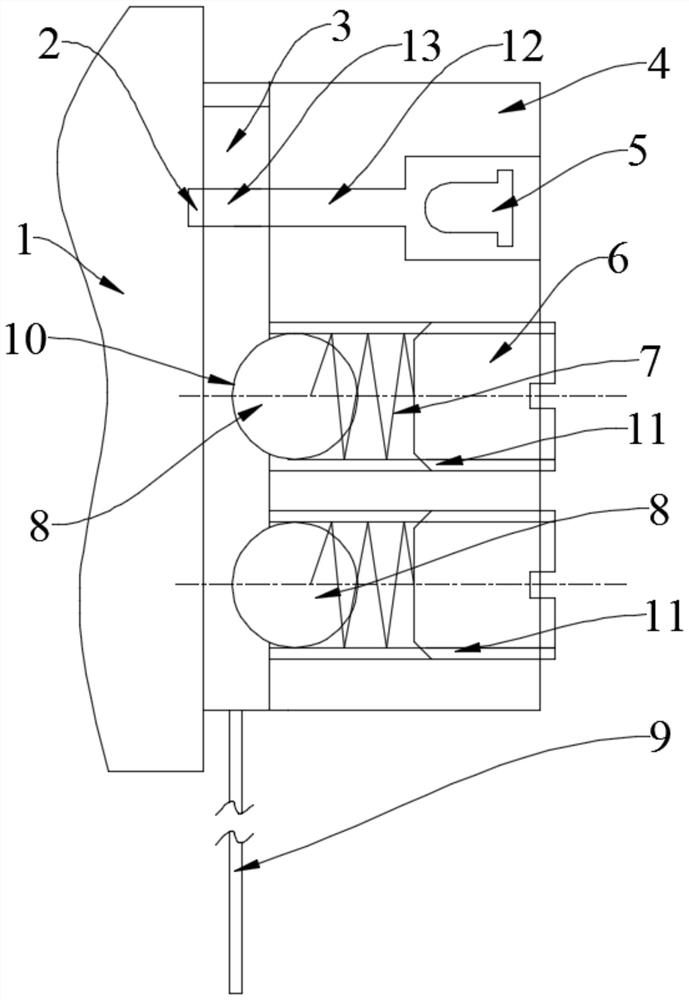

[0031] Example 2, such as image 3 As shown, the other structures are the same as in Embodiment 1, and the assembly method of the position detection device is different from that in Embodiment 1. Specifically, the fixed plate 4 is provided with a first through hole 12 leading to the slideway transversely, and the laser Transmitter 5 is installed in the first through hole 12, and described slide block 3 is provided with the second through hole 13 coaxial with first through hole 12, and described photoelectric receiver 2 is installed on base 1 and second. The position corresponding to the through hole 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com