Textile machine with multiple work stations and method for monitoring textile machine with multiple work stations

A textile machine and station technology, applied in textiles and papermaking, spinning machines, open-end spinning machines, etc., can solve problems such as production interruptions and achieve high productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

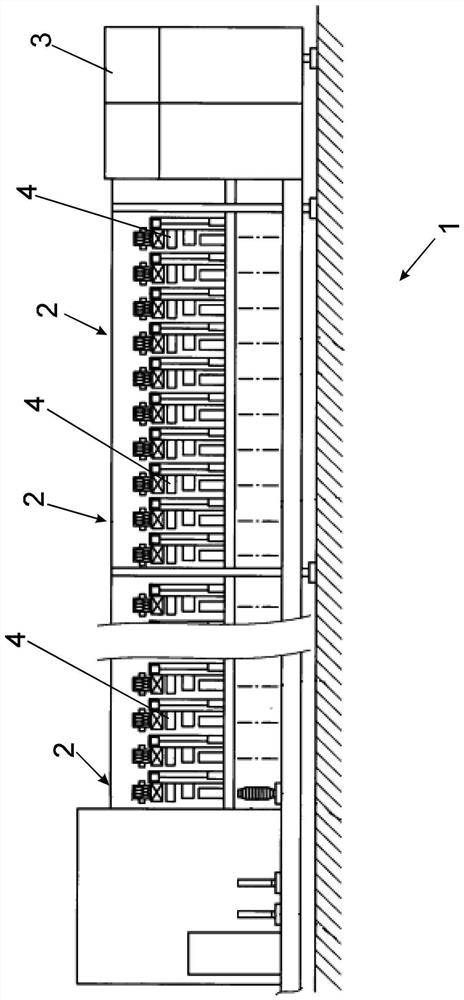

[0034] figure 1 An embodiment of a textile machine is shown schematically as a spinning machine 1 with a plurality of adjacently arranged spinning positions 2 , which form individual workstations of the textile machine. The control and monitoring of the spinning position 2 takes place via the central textile machine control unit 3 . An input unit (not shown here) on the textile machine control unit 3 allows the machine operator, inter alia, to input process parameters and to call up production characteristic parameters. In order to signal the spinning positions 2 that require maintenance, a signal unit 4 connected to the textile machine control unit 3 is provided on each spinning position 2 , and the signaling unit indicates the working status of the spinning positions 2 by means of colored light signals. Spinning positions 2 that are operating within the specified limit values are indicated by a green light signal. The spinning position 2 to be maintained is indicated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com