Double-warp double-weft brocade surface structure and weaving method thereof

A surface structure and tissue structure technology, applied in textiles, papermaking, fabrics, textiles, etc., can solve the problems of insufficient fineness, high density, and strong sense of thickness, and achieve the effect of beautiful reverse, thin thickness, and improved color purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

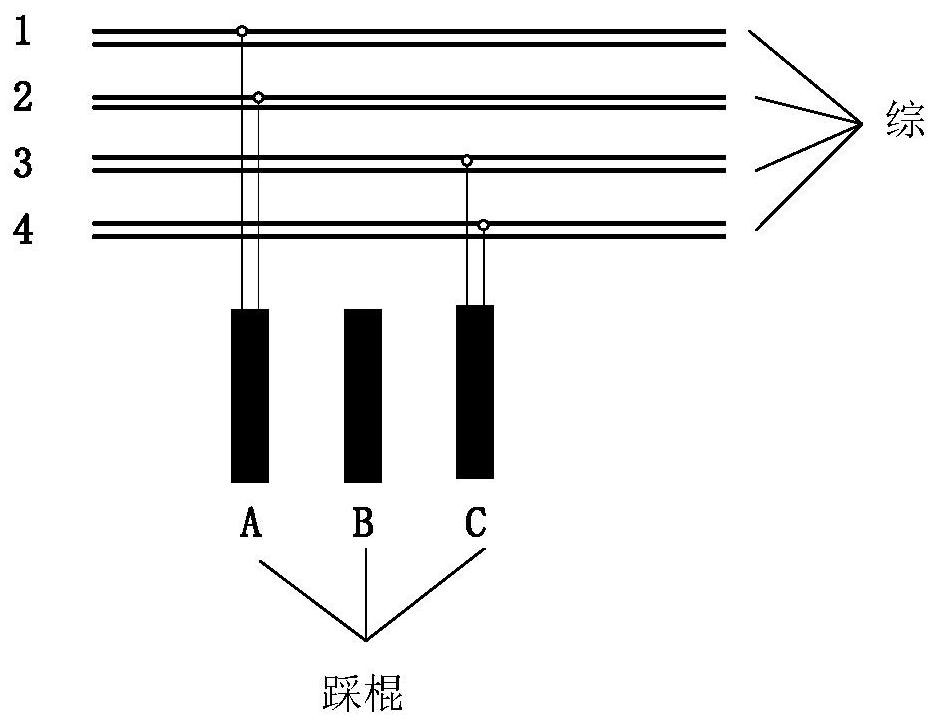

[0052] Such as figure 2 A weaving method of brocade with double warp and double weft is shown, comprising the following steps:

[0053] A. Connect the four sub-sheds of the heald to the two stepping sticks of the foot respectively. The four sub-sheds are No. 1 shed, No. 2 shed, No. 3 shed and No. 4 shed from top to bottom, and No. 3 shed and No. 4 shed. The upper warp of the No. 1 shed is used as the permanent pressing surface warp. Both the No. 1 and No. 2 sheds are connected to the A stepping stick, and the No. 3 and No. 4 sheds are connected to the C stepping stick;

[0054] B. Step on C and step on the stick, put A on the step on the stick, wear the color weft, and tighten;

[0055] C. Step on A and step on the stick, put C on the step on the stick, wear the bottom weft, and tighten;

[0056] D. Repeat the above steps B to C until the round is completed.

Embodiment 2

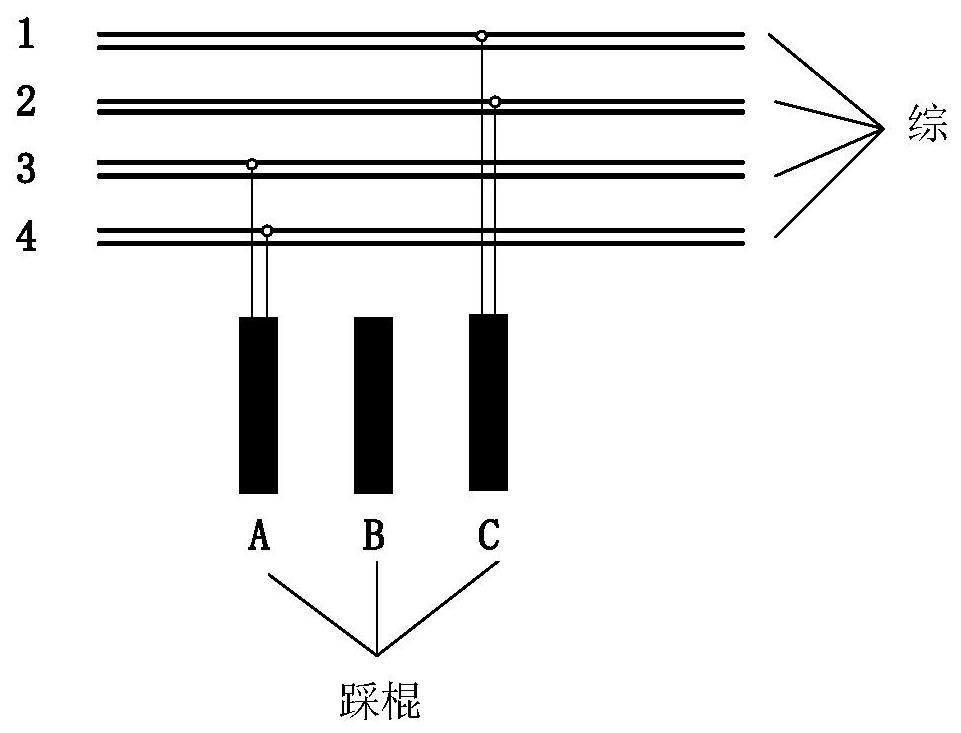

[0058] Such as image 3 A weaving method of brocade with double warp and double weft is shown, comprising the following steps:

[0059] A. Connect the four sub-sheds of the heald to the two stepping sticks of the foot respectively. The four sub-sheds are No. 1 shed, No. 2 shed, No. 3 shed and No. 4 shed from top to bottom, and No. 3 shed and No. 4 shed. The upper warp of the No. 1 shed is used as the permanent pressing surface warp. Both the No. 1 and No. 2 sheds are connected to the C stepping stick, and the No. 3 and No. 4 sheds are connected to the A stepping stick;

[0060] B. Step on A and step on the stick, put C on the step on the stick, wear the color weft, and tighten;

[0061] C. Step on C and step on the stick, put A on the step on the stick, wear the bottom weft, and tighten;

[0062] D. Repeat the above steps B to C until the round is completed.

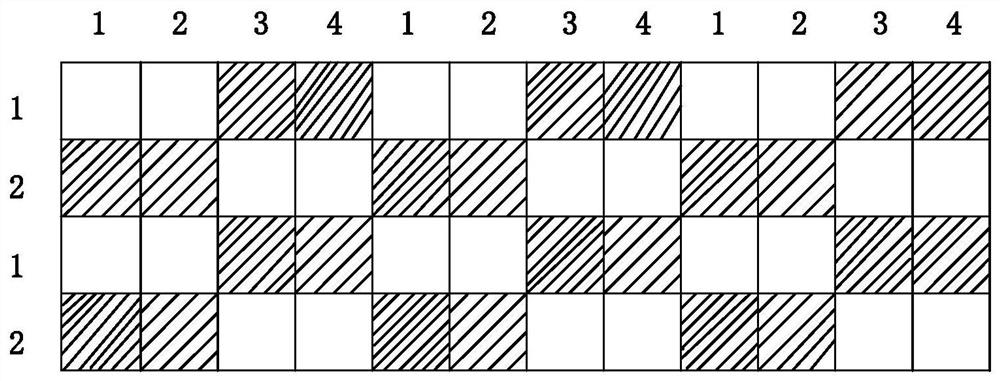

[0063] Such as figure 1 A double-warp and double-weft brocade surface structure is shown, manufactured by the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com