A flange with loose warning function

A flange and function technology, applied in the field of flanges with a loose warning function, can solve the problems of low maintenance efficiency, looseness, and heavy inspection and maintenance workload, so as to avoid accidents, improve warning effects, and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

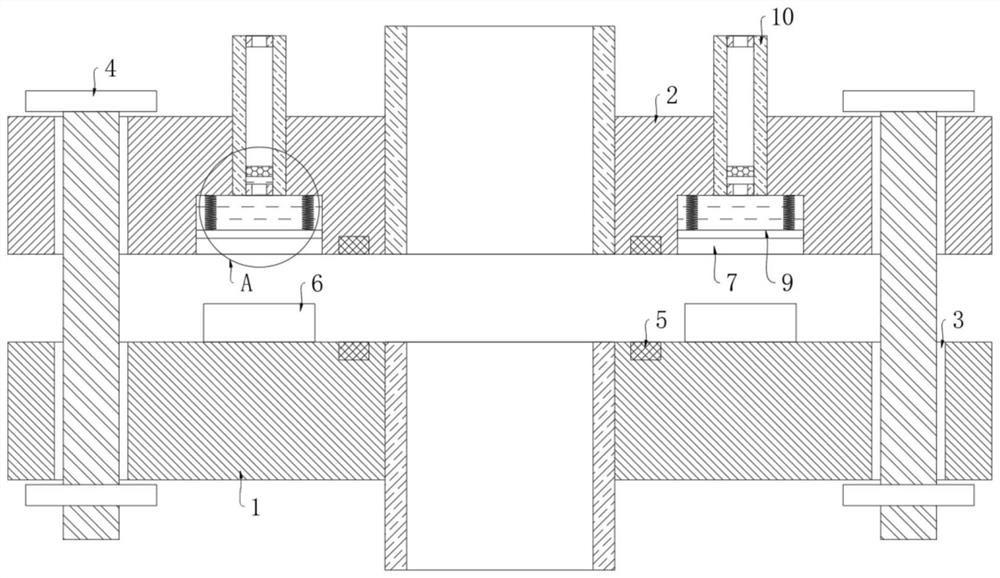

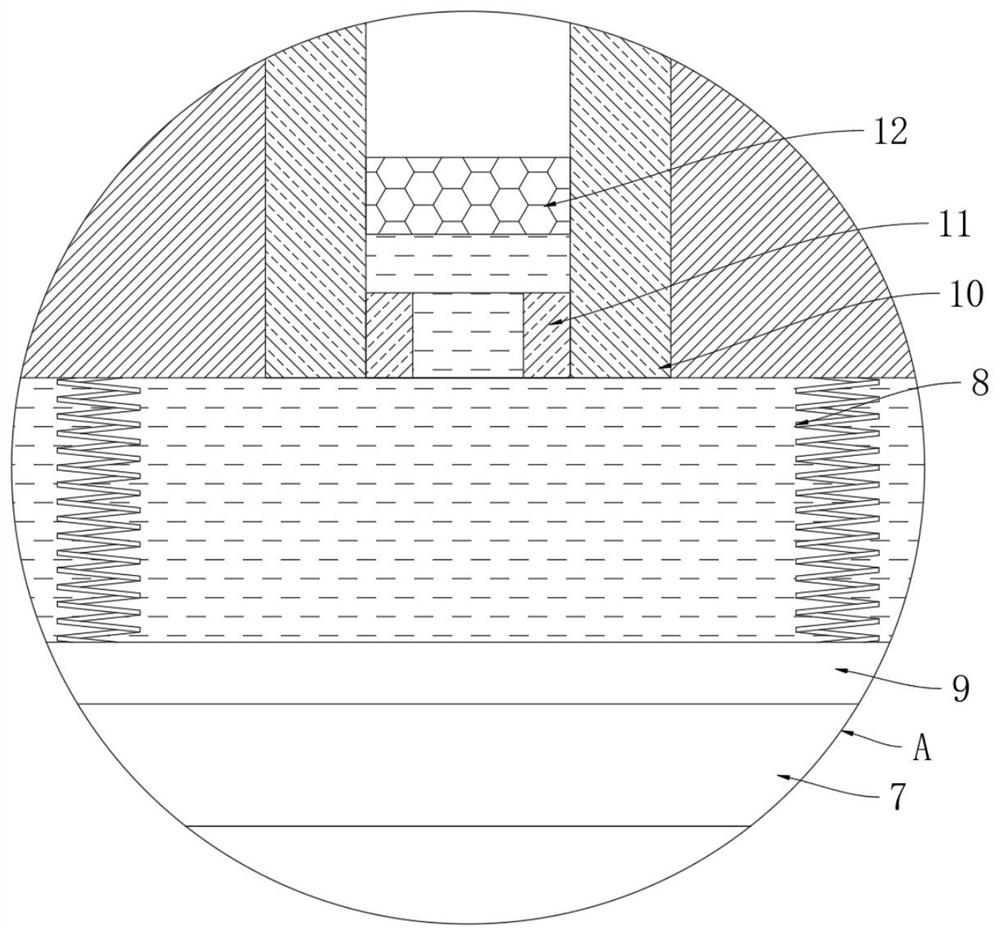

[0022] refer to Figure 1-3 , a flange with a loose warning function, including a first flange 1 and a second flange 2, the first flange 1 and the second flange 2 are correspondingly provided with a plurality of threaded holes 3, corresponding Locking bolts 4 are threaded in the two threaded holes 3, and the side of the first flange 1 close to the second flange 2 is evenly and fixedly connected with a plurality of blocks 6 corresponding to the locking bolts 4. A side of the second flange 2 close to the first flange 1 is evenly provided with a plurality of installation grooves 7 that cooperate with the block 6, and each installation groove 7 is elastically connected with a piston plate 9 by a return spring 8, and Each piston plate 9 is sealed and slidably connected with the groove wall of the corresponding installation groove 7 through a sealing ring. The sealed space formed by the piston plate 9 and the installation groove 7 is the driving area, and the driving area is filled ...

Embodiment 2

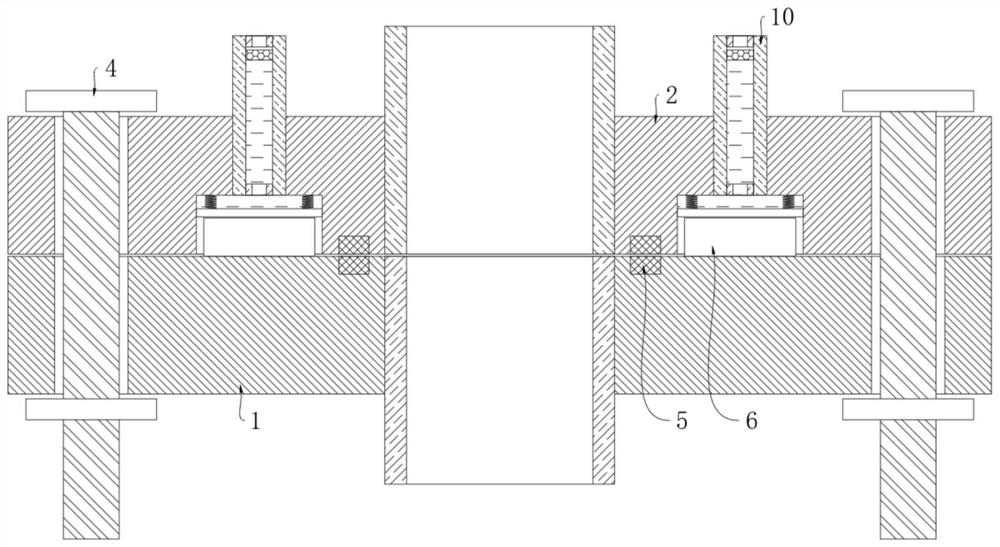

[0026] refer to Figure 4-5 The difference between this embodiment and Embodiment 1 lies in that: the inner wall of each display tube 10 is symmetrically embedded with conductive blocks 15, the indicating block 12 is made of conductive material, and the upper end surface of the second flange 2 is uniformly provided with multiple An alarm 14 corresponding to the display tube 10, a battery 13 is installed on the second flange 2, and the corresponding two conductive blocks 15 and the alarm 14 are electrically connected to the battery 13 through wires.

[0027] This embodiment can illustrate its functional principle through the following operation mode: when any locking bolt 4 is loosened so that the indicating block 12 in the corresponding display tube 10 moves downward, the indicating block 12 is offset against the two conductive blocks 15, and the circuit Conduction, the corresponding alarm 14 works, and the alarm 14 actively sends out a warning signal, so that the patrol perso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com