Coiled optical fiber supporting frame

A technology of support frame and optical fiber, applied in the field of support frame, can solve the problems of inability to adjust, inconvenient installation of support frame, and insufficient comprehensiveness, and achieve the effect of convenient installation and stable connection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

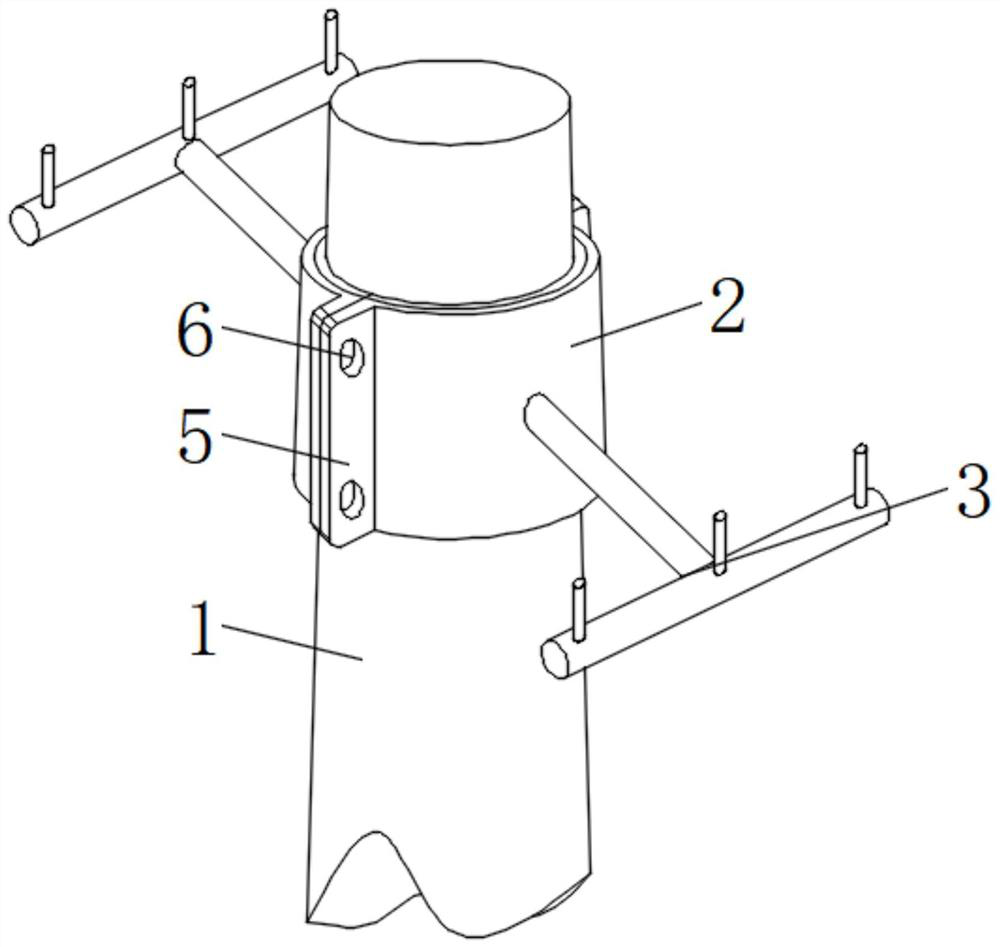

[0024]Such asfigure 1 As shown, a tray-mounted optical fiber support frame includes a support column 1, a support sleeve 2 is provided on the outer surface of the support column 1, and an adjustment structure 3 is provided on the outer surface of the support sleeve 2. The adjustment structure 3 includes a transverse connecting column 31 and a matching The connecting column 32, the threaded hole 33, the connecting thread 34 and the threaded connecting column 35 are provided with a rubber layer 4 on the inner side of the support sleeve 2, a connecting plate 5 is provided on one side of the support sleeve 2, and a connecting plate is provided on the outer surface of the connecting plate 5. Hole 6.

Embodiment 2

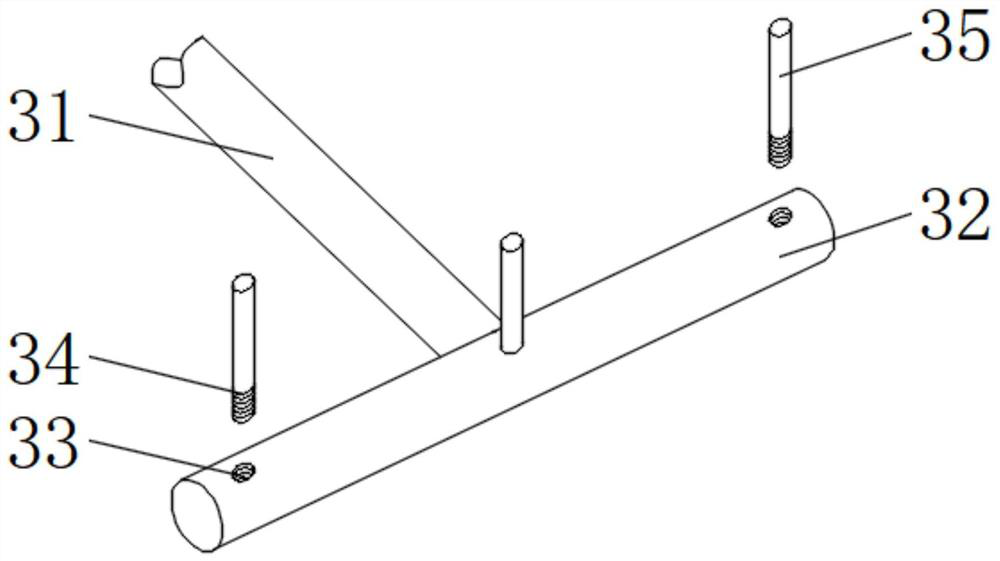

[0026]On the basis of Example 1, such asfigure 2 As shown, the horizontal connecting column 31 is provided on the outer surface of the support sleeve 2, the matching connecting column 32 is provided on the outer surface of the top end of the horizontal connecting column 31, the threaded hole 33 is provided on the outer surface of the upper end of the matching connecting column 32, and the threaded connecting column 35 is provided with Inside the threaded hole 33, the lower end of the threaded connecting column 35 is provided with a connecting thread 34, which is beneficial to the layout effect between the support frame components.

[0027]The number of adjustment structures 3 is two groups, the horizontal connecting column 31 and the support sleeve 2 are fixedly connected, the matching connecting column 32 and the horizontal connecting column 31 are fixedly connected, and the number of threaded holes 33 on the single adjusting structure 3 is three. The threaded hole 33 is matched with ...

Embodiment 3

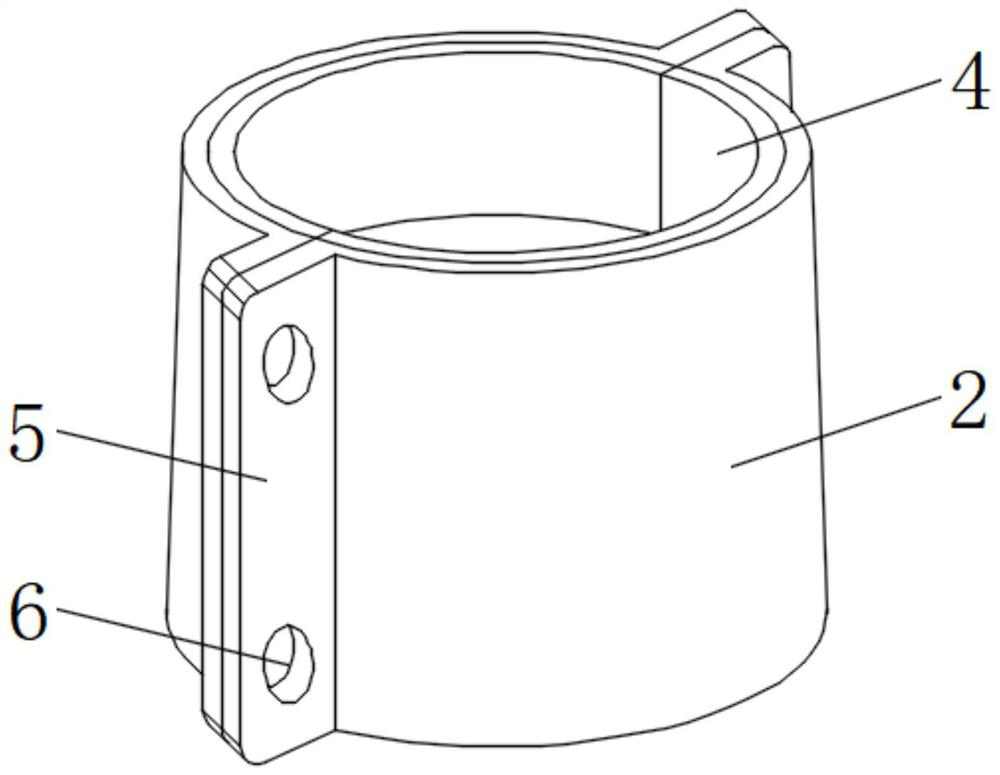

[0029]On the basis of Example 1 and Example 2, such asimage 3 ,4As shown, the number of support sleeves 2 is two groups, the support sleeves 2 are in the shape of a semicircular hollow column, the two groups of support sleeves 2 are in the shape of a hollow truncated cone when the inner side is attached, and the support sleeve 2 and the rubber layer 4 are movably connected. The rubber layer 4 is matched with the supporting sleeve 2, and the rubber layer 4 is matched with the supporting column 1, which is beneficial to the connection between the rubber layer 4 and the supporting sleeve 2.

[0030]The number of connecting plates 5 is four groups, the connecting plates 5 are arranged in a vertical strip shape, the connecting plates 5 and the supporting sleeve 2 are fixedly connected, and the connecting plates 5 are arranged symmetrically, which is beneficial to the connection between the connecting plate 5 and the supporting sleeve 2. Stable effect of the connection between.

[0031]The numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com