A preparation device and method for abrasive tools with three-dimensional controllable arrangement of abrasive grains

A technology for preparing devices and abrasive particles, applied in grinding devices, grinding/polishing equipment, manufacturing tools, etc., can solve the problem that there is no operable method for the three-dimensional controllable arrangement of abrasive particles with resin bond, and the abrasive particles cannot be fully realized. Controllable arrangement and other issues to achieve the effect of solving the movement of abrasive particles, good arrangement effect and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

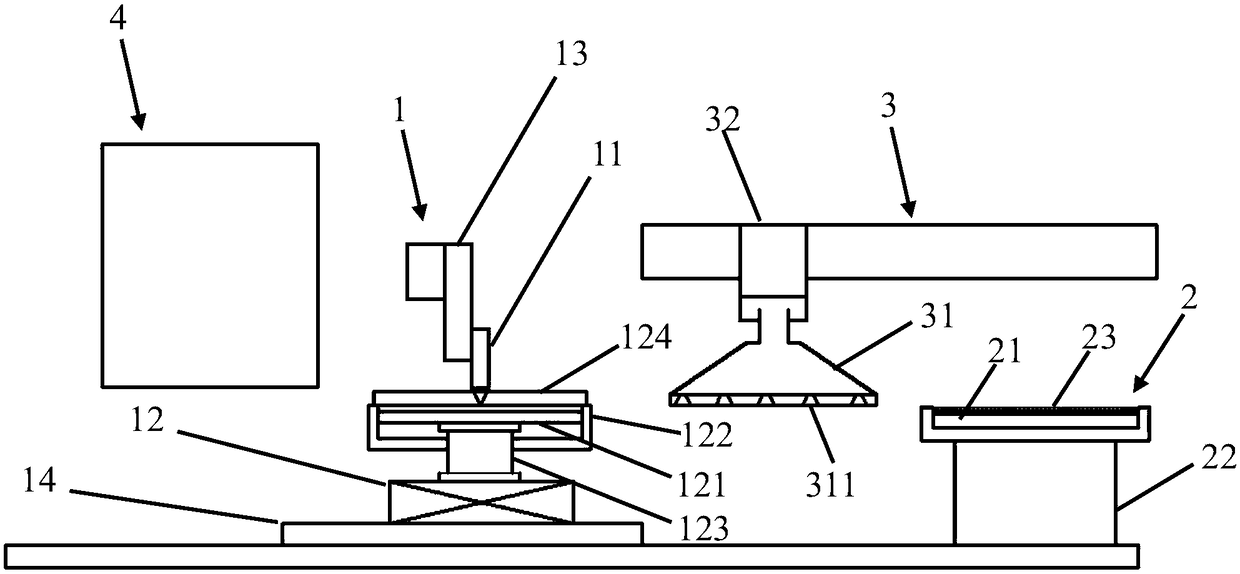

[0032] refer to figure 1 , a preparation device for abrasives with three-dimensional controllable arrangement of abrasive grains of the present invention, a coating mechanism 1, an abrasive placement mechanism 2, an abrasive arrangement mechanism 3 and a curing mechanism 4.

[0033] The coating mechanism 1 includes a coating component 11 and a coating platform 12 , and the coating component 11 is used for coating a predetermined thickness of resin on the coating platform 12 . Specifically, the coating platform 12 includes a coating pan 121, a coating pan cover 122, and a lift frame 123. The coating pan cover 122 is closely matched with the periphery of the coating pan 121 and is wound around the outside of the coating pan 121, and the lift frame 123 is connected. The coating pan 121 drives the coating pan 121 to move up and down relative to the coating pan cover 122 . At the beginning, the coating pan 121 is flush with the upper edge of the coating pan cover 122, and the lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com