Grain structure three-dimensional numerical prediction method in molten metal one-way solidification process

A unidirectional solidification and three-dimensional numerical technology, which is applied in the field of metal material processing, can solve the problems of large amount of calculation in three-dimensional numerical prediction, and does not consider the influence of grain growth at the solid-liquid interface, so as to shorten the research and development cycle, increase the calculation speed, and accelerate The effect of regulating progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

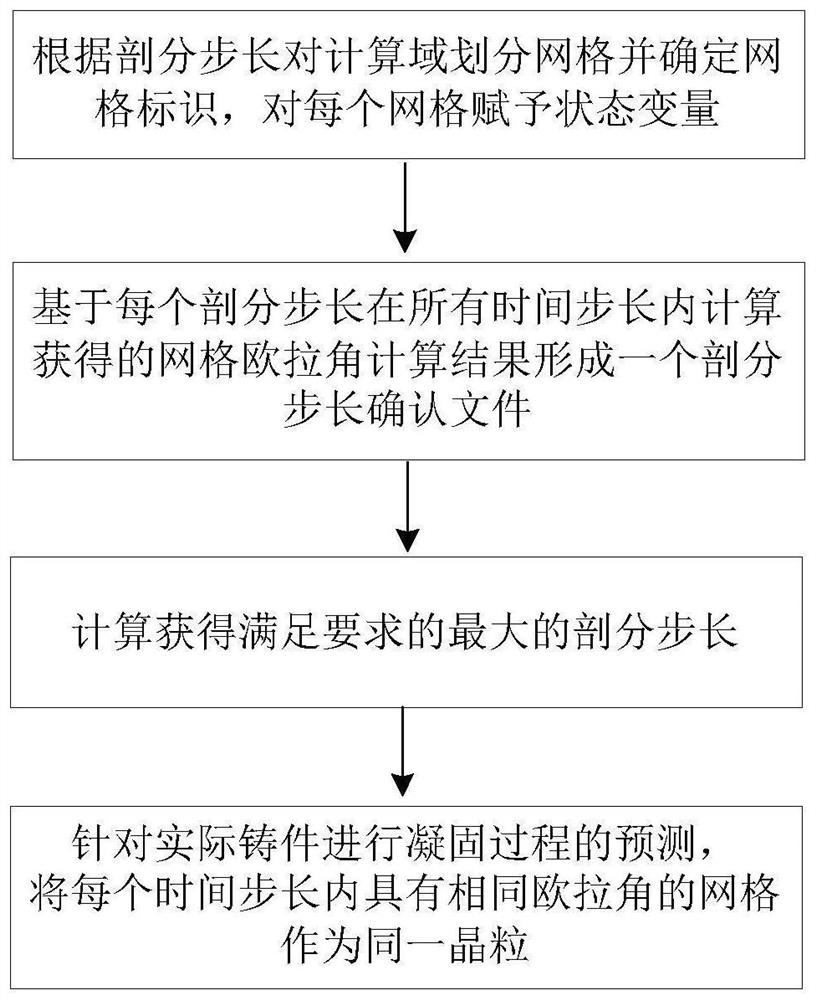

[0035] Specific implementation mode 1. Combination figure 1 As shown, the present invention provides a method for three-dimensional numerical prediction of grain structure in the process of unidirectional solidification of molten metal, comprising:

[0036] Step 1: Set the calculation domain of the assumed unidirectional solidification process of the casting, and select the subdivision step size Δx of the calculation domain in the direction of each coordinate axis in the conventional three-dimensional coordinate system CA , according to the subdivision step size Δx CA Divide grids for the calculation domain and determine the grid ID; assign state variables to each grid based on the grid ID; because it is a one-way solidification process, it is only calculated for castings.

[0037] Step 2: Select the subdivision step size Δx CA Sensitivity test of post-calculation results to grid size:

[0038] Select the subdivision step size Δx of different sizes in order from small to la...

specific Embodiment

[0155] The model alloy is a Ni-based superalloy (Ni-5wt%Nb). The alloy thermophysical parameters and simulation parameters are shown in Table 1. The technical parameters of the unidirectional solidification process are shown in Table 2.

[0156] Table 1 Thermal physical parameters of Ni-5wt%Nb alloy and parameters required for simulation

[0157]

[0158] Table 2 process parameters

[0159]

[0160]

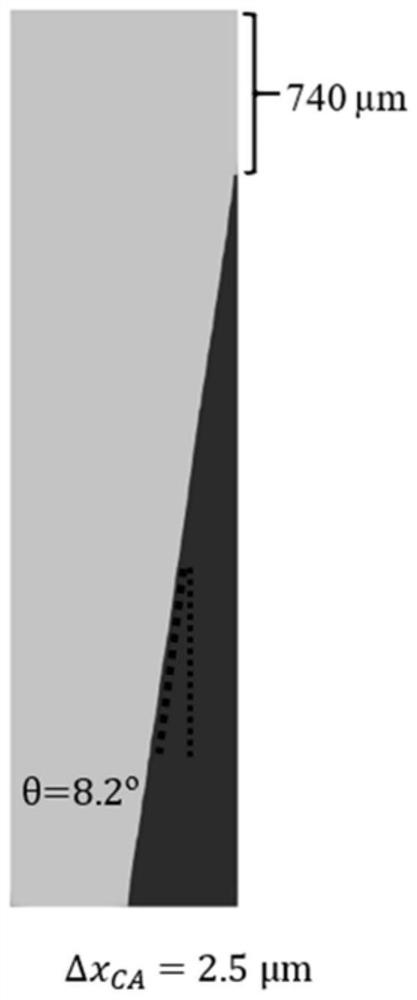

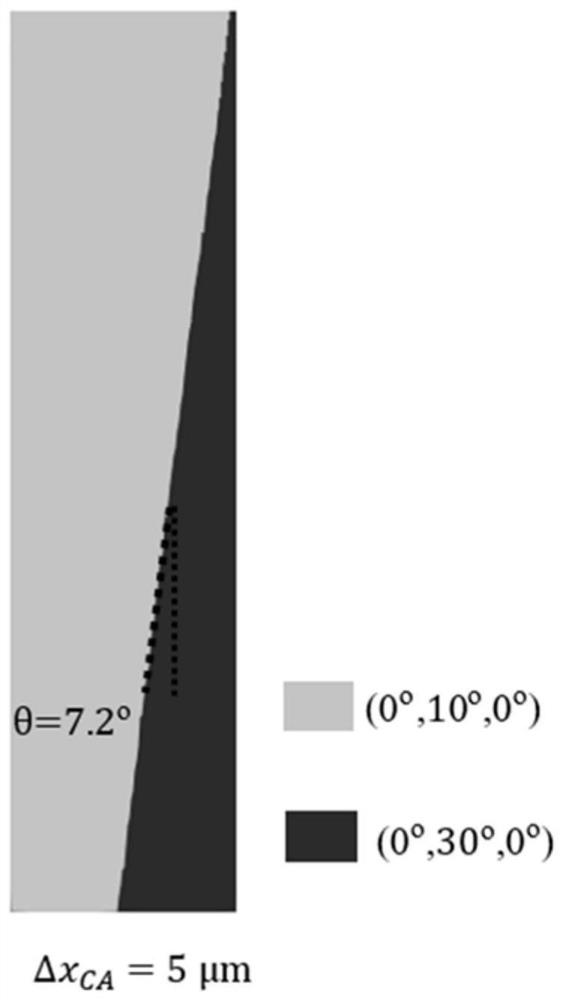

[0161] figure 2 and image 3 The corresponding process parameter one is G=50°C / m, The corresponding parameters are shown in Table 1. The competitive growth of columnar crystals was studied when the grid size was 2.5 μm and 5 μm, respectively. The Euler angles of columnar crystals are (0°, 10°, 0°) and (0°, 30°, 0°), respectively. It can be seen that although the grid size has a certain influence on the final height of the grain growth, it has little effect on the angle of the grain boundary (the angle of the grain boundary is 8.2° and 7.2°, respectively). The a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap