Vibration damper having adjustable damping valve

A technology of vibration damper and damping adjustment, which is applied in the direction of shock absorber, shock absorber, spring/shock absorber, etc., to achieve the effect of optimizing structural space utilization, high stability, and simple closed technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

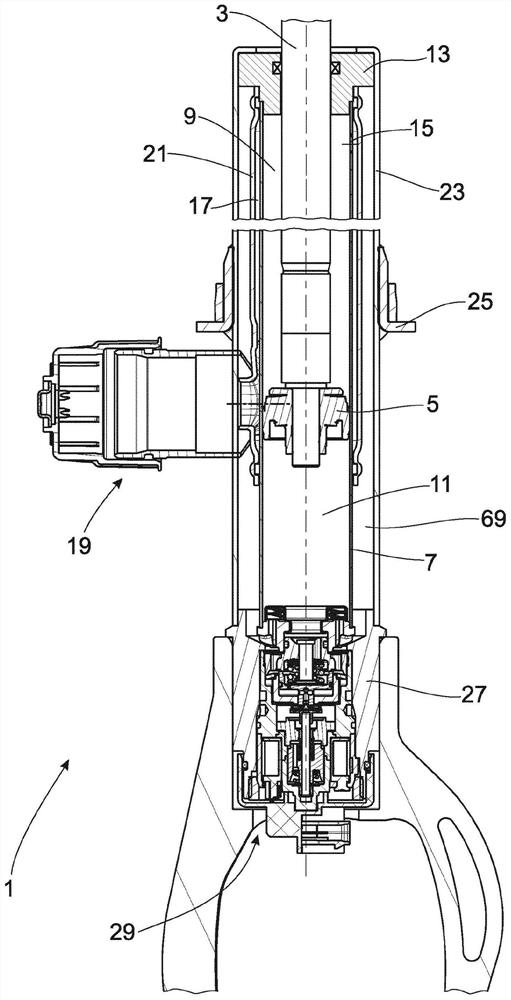

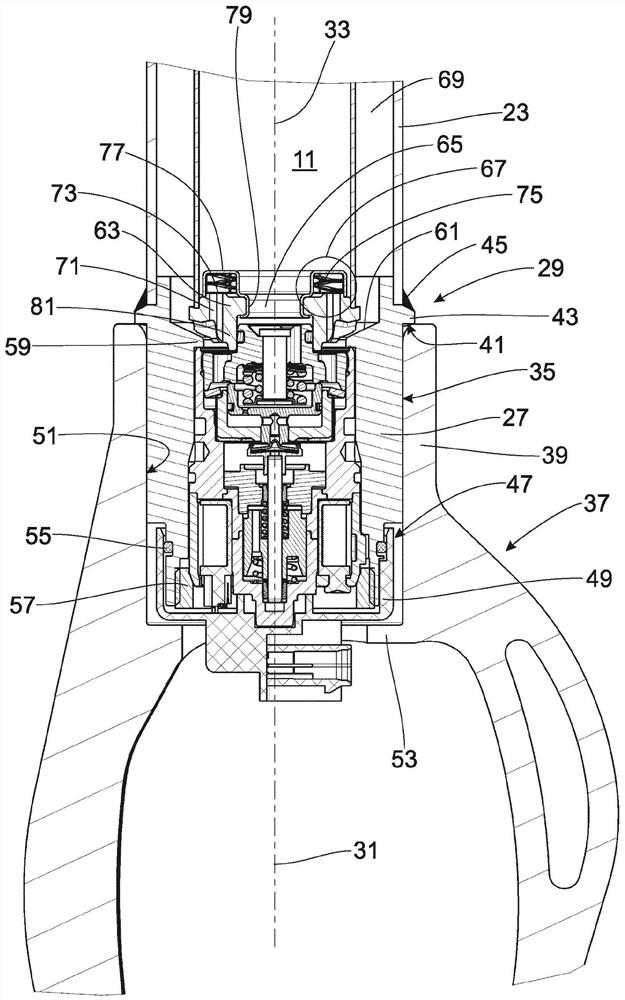

[0021] figure 1 A complete section through a vibration damper 1 with a piston rod 3 with a piston 5 , axially displaceable in an inner cylinder 7 , is shown. Optionally, the piston 5 can be equipped with a damping valve and divide the cylinder 7 into a working space 9 on the piston rod side and a working space 11 remote from the piston rod. The piston rod-side working space 9 is closed at the end by a piston rod guide 13 . Both the working space 9 on the piston rod side and the working space 11 remote from the piston rod are filled with customary hydraulic damping medium.

[0022] The inner cylinder 7 can have an overflow bore 15 which connects the piston rod-side working space 9 with an adjustable damping valve 19 by means of a fluid connection 17 . The fluid connection 17 is formed by an intermediate tube 21 which is pressed tightly against the outer side of the inner cylinder 7 . The inner cylinder 7 as well as the intermediate tube 21 are surrounded by an outer containe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com