Automatic drainage device and method for continuous extraction of downward crossing drill hole

A layer-penetrating drilling and automatic drainage technology, which is applied in mining equipment, drainage, safety devices, etc., can solve the problems of gas concentration, reverse osmosis, large water accumulation, and low drainage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

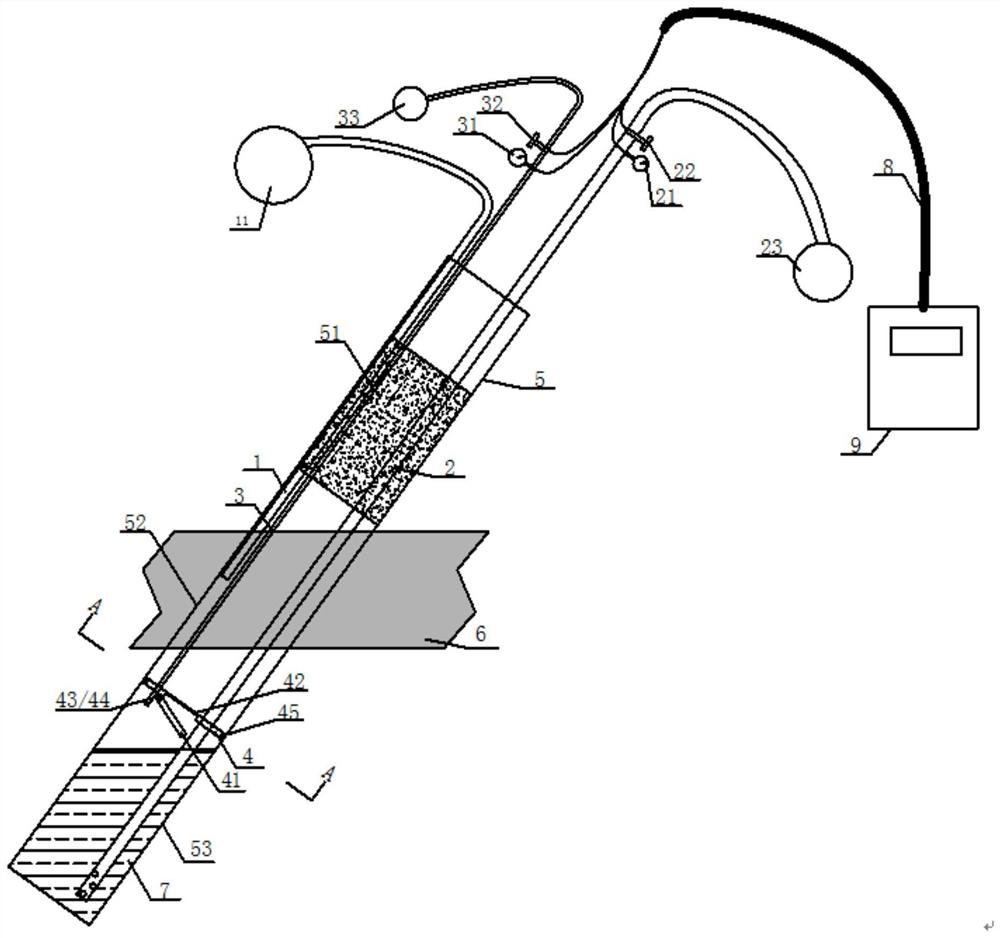

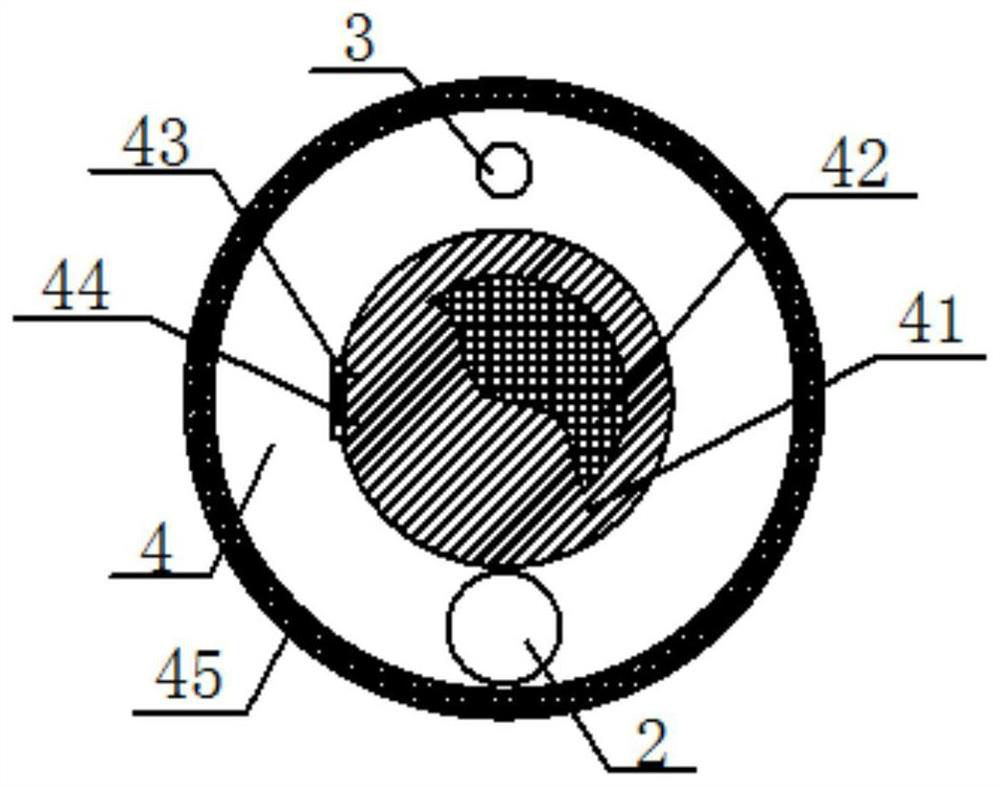

[0028] Such as Figure 1-Figure 2 As shown, the automatic drainage device for the continuous drainage of downward drilling through the layer proposed in this embodiment is used to discharge the accumulated water 7 in the drainage drilling 5, the drainage drilling 5 passes through the coal seam 6 and extends downward, and the drainage The hole opening of the borehole 5 is provided with a sealing section 51, including the extraction pipe 1, the drainage pipe 2, the compressed air pipe 3, the one-way filter plate 4, the gas extraction system 11, the drainage system 23 and the compressed air system 33 , wherein the one-way water filter plate 4 is arranged between the coal seam 6 and the bottom of the hole, the water storage section 53 is formed between the one-way water filter plate 4 and the hole bottom, and the pumping section is formed between the one-way water filter plate 4 and the hole sealing section 51. In the mining section 52, the inner end of the hole of the extraction ...

Embodiment 2

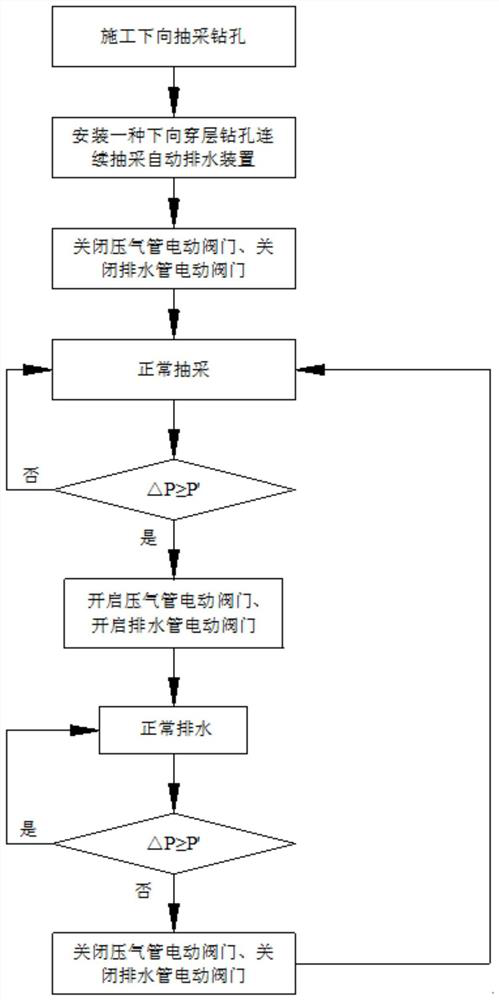

[0038] Such as Figure 1-Figure 3 As shown, the automatic drainage method for continuous drainage of downward drilling through layer drilling proposed in this embodiment uses the automatic drainage device for continuous drainage of downward drilling through layer drilling in Example 1, including the following:

[0039] Utilize the drilling rig to construct the down-through layer drilling of claim 1, the extraction borehole 5 passes through the coal seam 6, and the water storage section 53 is located in the rock layer under the coal seam 6; the drain pipe 2 and the pressure air pipe 3 are sealed and inserted into the one-way filter Water plate 4, and sealant 45 is wrapped on the periphery of one-way water filter plate 4, put into extraction borehole 5 to predetermined depth synchronously with extraction pipe 1, seal hole with sealing device to extraction borehole 5; Install the compressed air pipe pressure sensor 31, the compressed air pipe electric valve 32, the drain pipe pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com