A Continuous Observation Ruler for Building Cracks

A technology for buildings and cracks, applied in the direction of mechanical gap measurement, etc., can solve the problems of lack of continuity, low accuracy of crack measurement, and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

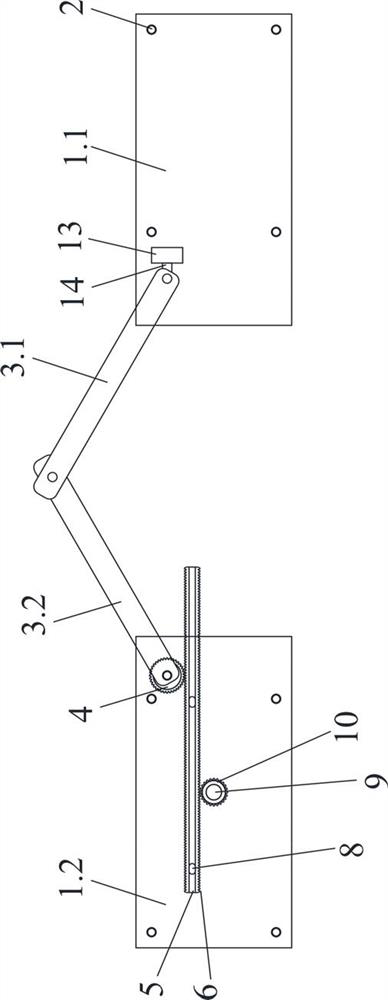

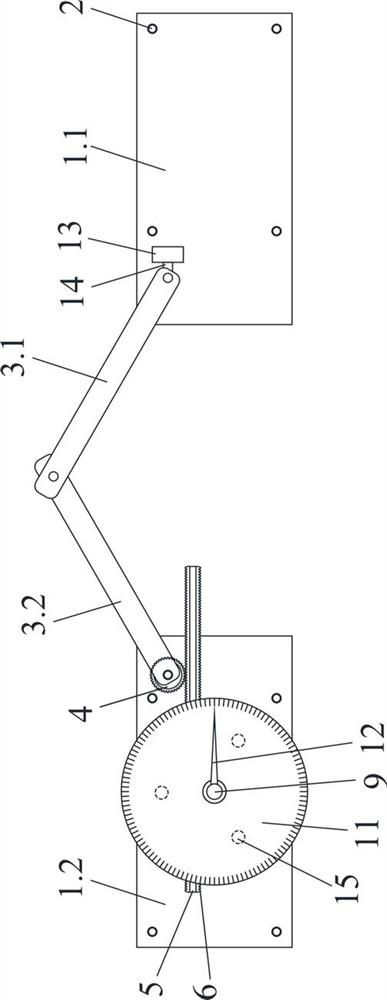

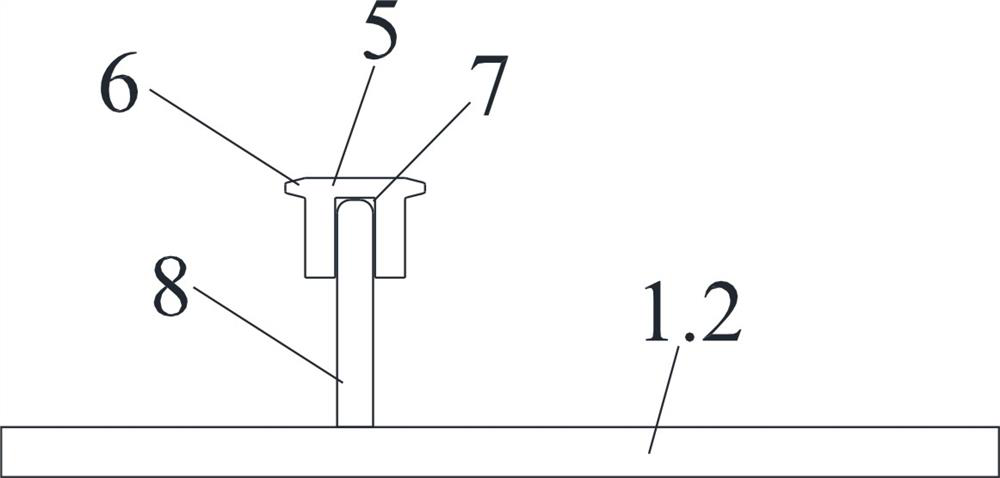

[0025] like Figure 1-4 As shown, a continuous observation ruler for building cracks includes a first fixing plate 1.1 and a second fixing plate 1.2; the first fixing plate 1.1 and the second fixing plate 1.2 are respectively reserved with four evenly distributed fixing holes 2 ; The second fixing plate 1.2 and the first fixing plate 1.1 are arranged at right and left intervals, the left end of the first fixing plate 1.1 is hinged with the first rigid conducting rod 3.1 (stainless steel material), and the right end of the second fixing plate 1.2 is installed with a can 360 °The rotating rigid transmission rod direction changing gear 4, the top of the rigid transmission rod direction changing gear 4 is hinged with a second rigid transmission rod 3.2 (stainless steel material), the left end of the first rigid transmission rod 3.1 and the right end of the second rigid transmission rod 3.2 Live hinged together; on the second fixed plate 1.2 outside the direction changing gear 4 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com