Flow type defect detection method based on diamagnetic levitation principle

A defect detection and magnetic levitation technology, which is applied in the field of flow defect detection based on the principle of anti-magnetic levitation, can solve problems such as high detection cost, complicated operation, and slow detection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

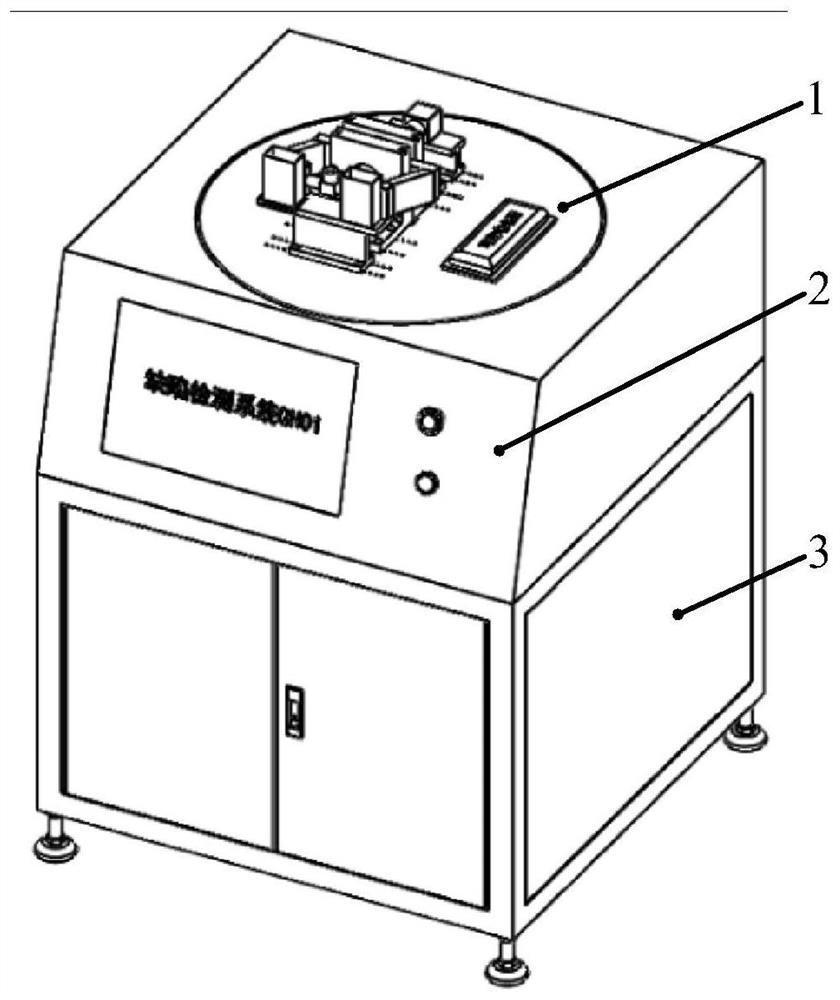

[0025] Such as figure 1 As shown, this embodiment relates to a flow-type defect detection device based on the principle of anti-magnetic levitation, including: a rotating detection platform 1, an electric control box 2 and a frame 3, wherein: the rotating detection platform 1 and the electric control box 2 are both set Above the rack 3; by setting the parameters of the electric control box 2 to adjust the rotation speed of the rotating detection platform 1 to obtain multiple stable suspension poses of the test sample, thereby obtaining the internal defect distribution of the test sample 21.

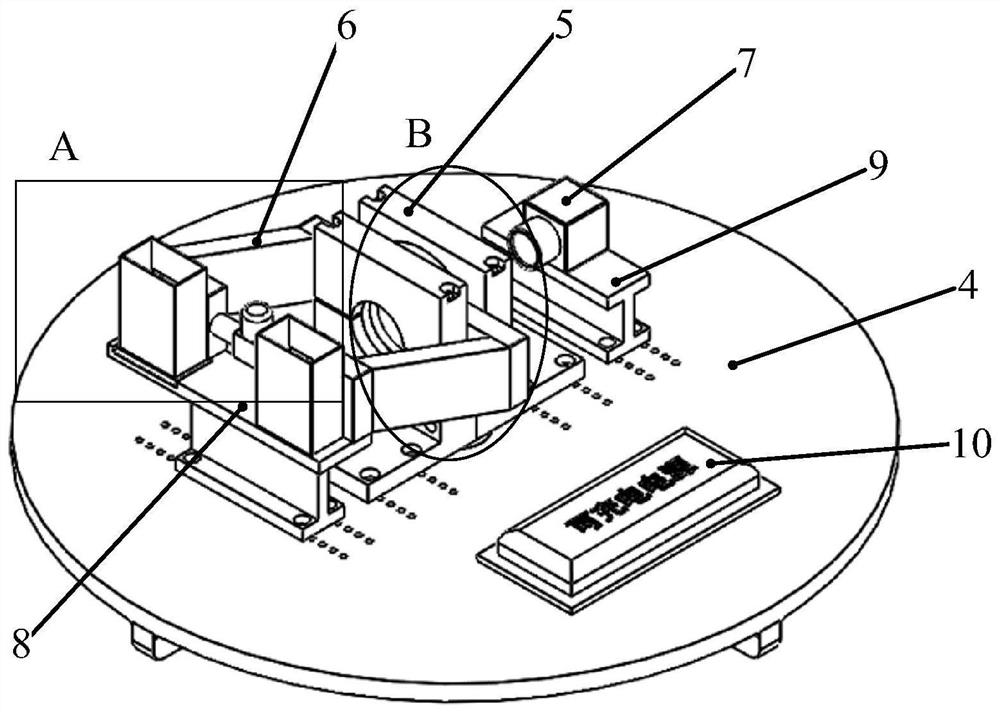

[0026] Such as figure 2 As shown, the rotating detection platform 1 includes: a test platform 4 and a magnetic space structure assembly 5 arranged thereon, a detection flow channel 6, a wireless transmission camera 7, a detection flow channel support frame 8, a camera mounting frame 9 and A rechargeable power supply 10, wherein: the detection channel 6 passes through the magnetic space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com