Ceramic bushing glazing equipment fixing assembly

A technology for fixing components and equipment, which is applied in the field of glazing of ceramic sleeves, and can solve problems such as the influence of glazing quality and the shaking of ceramic sleeves of capacitors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

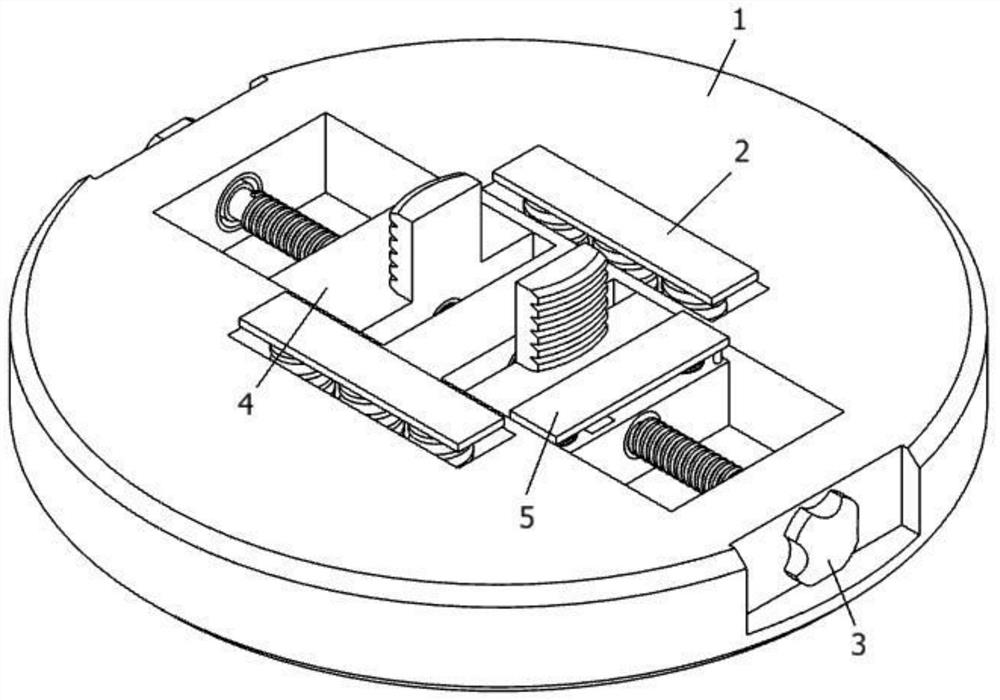

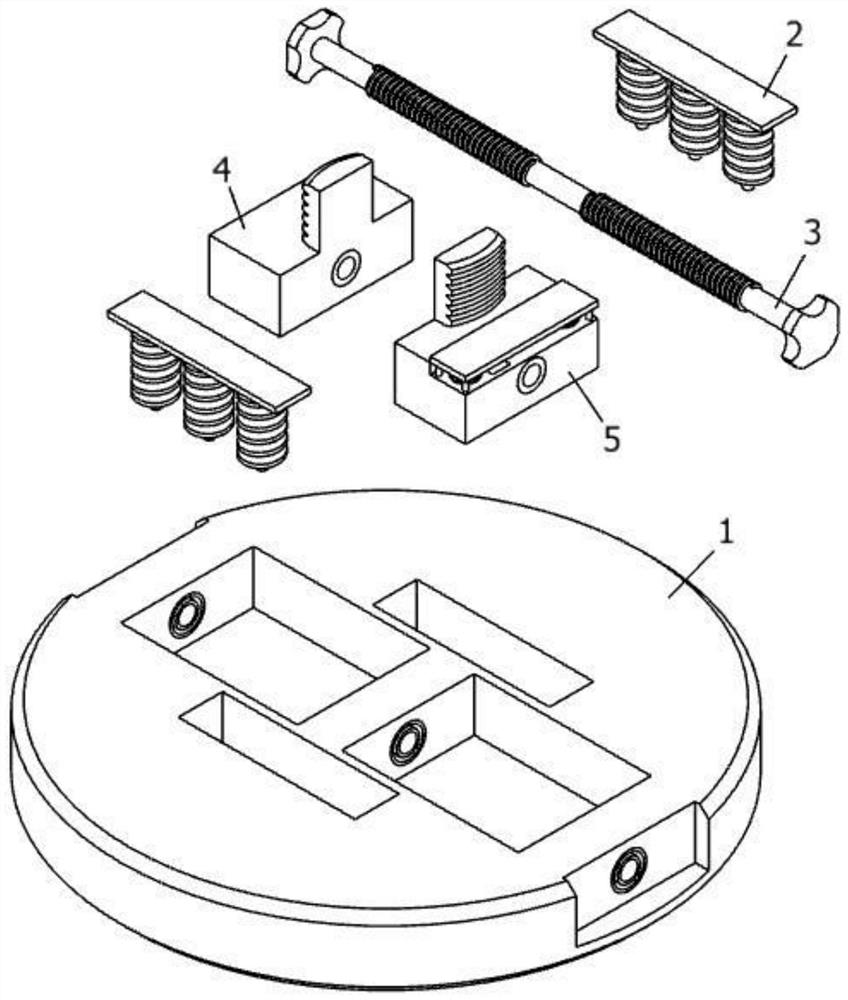

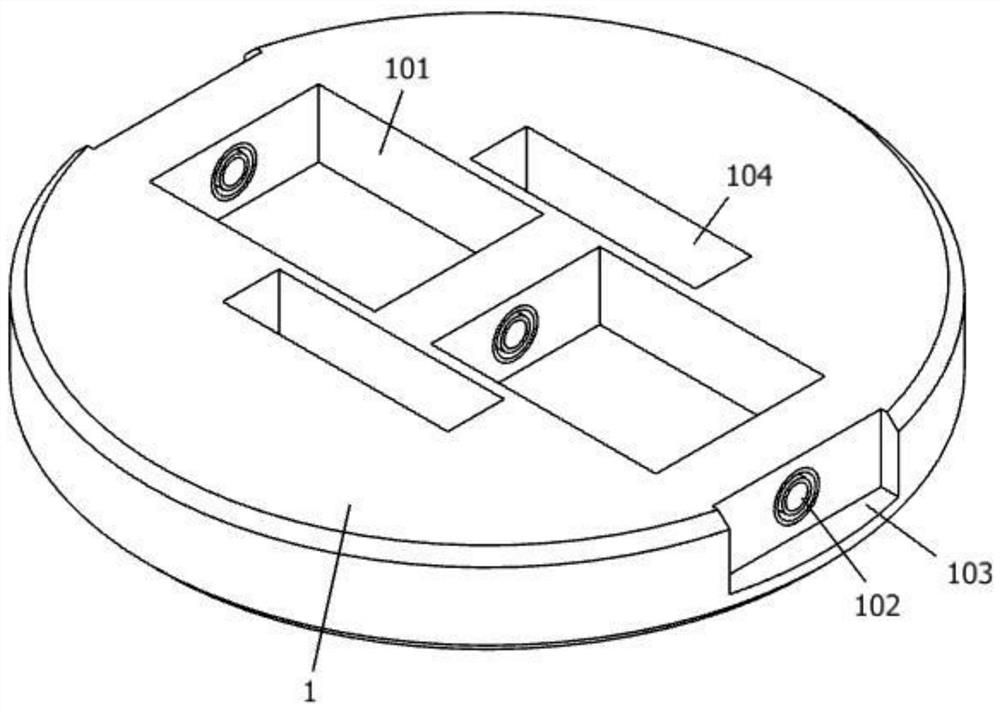

[0034] as attached figure 1 to attach Figure 11 Shown:

[0035] The present invention provides a fixed assembly for ceramic sheath glazing equipment, including: a working turntable 1, a top punching mechanism 2 is fixedly installed on the left and right sides of the top surface of the working turntable 1, and a bidirectional transmission mechanism 3 is installed on the working turntable 1 for rotation; The turntable 1 includes a rectangular sliding groove 101, a bearing 102, a missing groove 103, a rectangular storage groove 104, and a circular limit chute 105. The top surface of the working turntable 1 is left-right symmetrical and has two rectangular storage grooves 104. , the inner bottom surface of each rectangular storage groove 104 is evenly distributed forward and backward, and three circular limit chutes 105 are respectively provided, and the top surface of the working turntable 1 is symmetrical in front and rear. A group of bearings 102 are embedded in the adjacent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com