Self-moving type writing brush waste hair removing device

A self-moving, brush technology, which is applied to the device for removing the pen tip, repairing ink pen, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

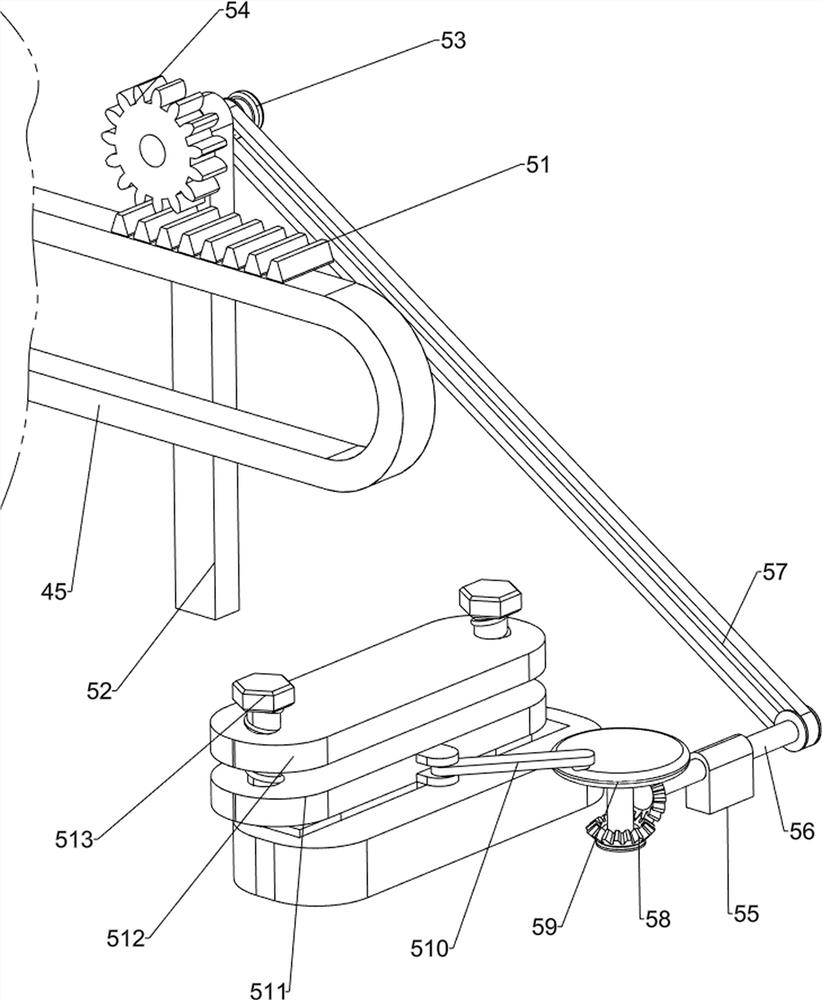

[0049] A self-moving type cleaning brush waste hair device, such as figure 1 with figure 2 As shown, it includes a base 1, a water frame 2, a support 3, a moving mechanism 4 and a reciprocating mechanism 5, a water frame 2 is placed on the base 1, and the left and right sides of the base 1 are symmetrically provided with supports 3 and four supports 3 A moving mechanism 4 is arranged on the top, and a reciprocating mechanism 5 is arranged on the right side of the base 1, and the reciprocating mechanism 5 is connected with the moving mechanism 4.

[0050] In the brush production process, it is necessary to clean the tip of the brush to remove waste hair, but manual cleaning is time-consuming and laborious. This equipment can help people save time and energy. First, people fix a row of brush holders in the reciprocating mechanism 5, and make the brush The nib is put into the water frame 2, and then the moving mechanism 4 is operated manually, and the moving mechanism 4 is oper...

Embodiment 2

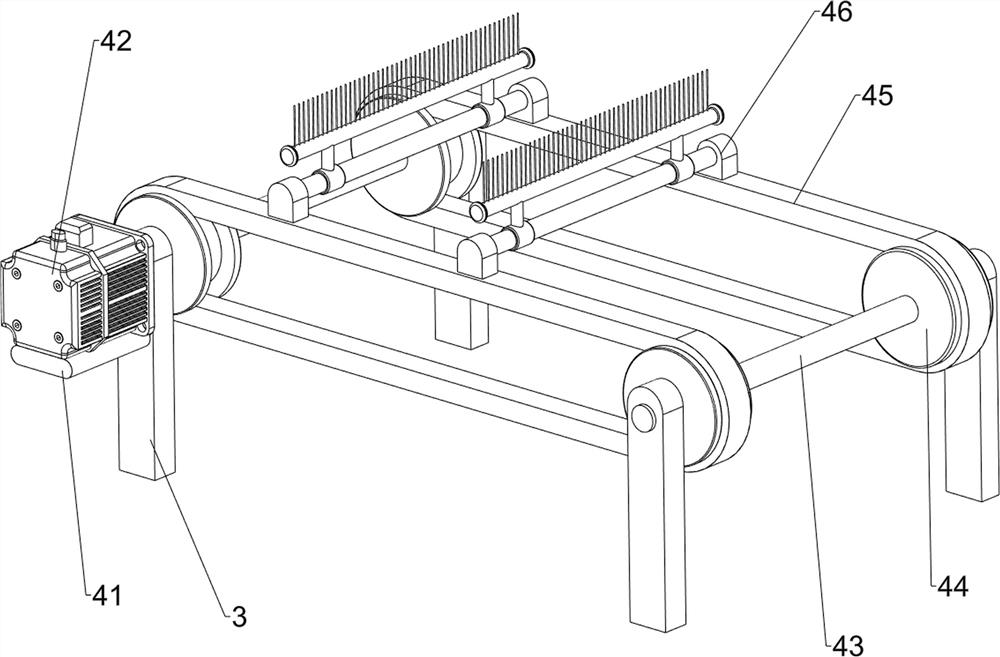

[0052] On the basis of Example 1, such as figure 2 with image 3 As shown, the moving mechanism 4 includes a mounting plate 41, a motor 42, a first rotating shaft 43, a pulley 44, a flat belt 45 and a straight comb 46, and the first support 3 at the left front portion is provided with a mounting plate 41, the mounting plate Motor 42 is installed on 41, and the support 3 tops of the both sides of front and back are all rotatably connected with first rotating shaft 43, and the first rotating shaft 43 on the left side is connected with motor 42 output shafts, and two first rotating shafts 43 front and rear parts are all provided with Belt pulley 44, is wound with flat belt 45 on the belt pulley 44 of left and right sides, is connected with two straight combs 46 on two flat belts 45.

[0053] People put a row of writing brush nibs into the water frame 2, manually make its penholder fixed, and then start the motor 42, the output shaft of the motor 42 rear side rotates to drive th...

Embodiment 3

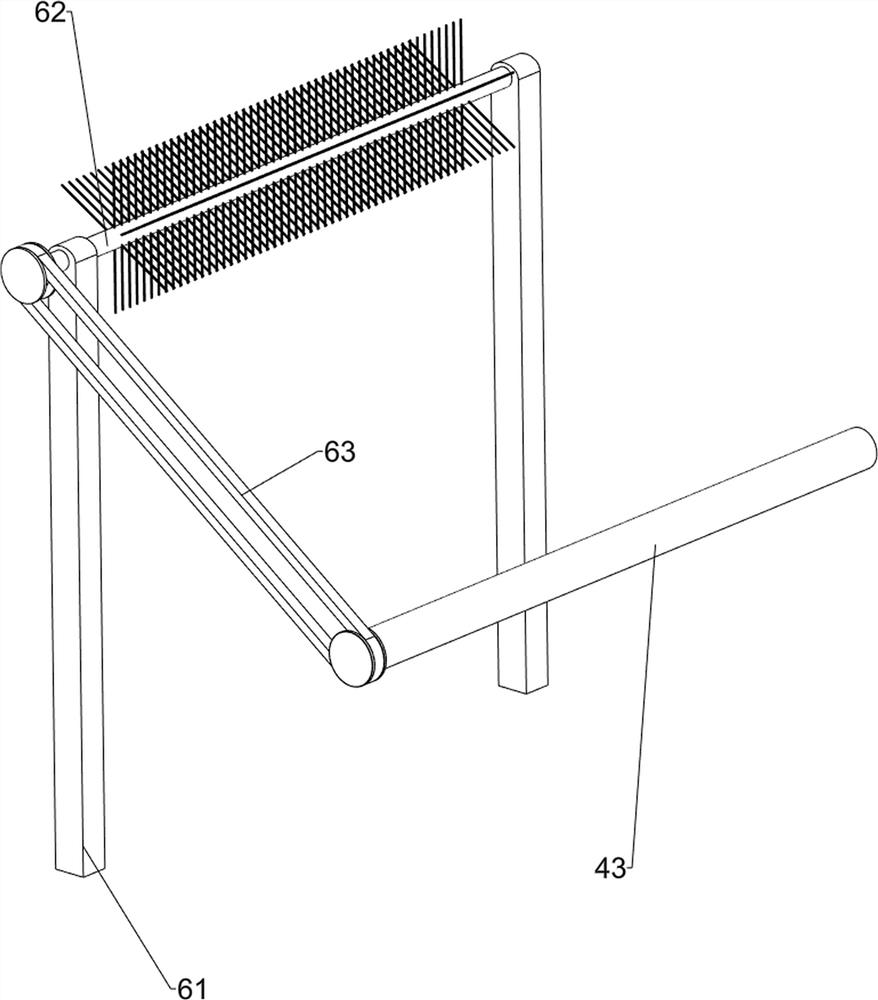

[0057] On the basis of Example 2, such as figure 1 with Figure 4 As shown, it also includes a waste removal mechanism 6, which is installed on the base 1. The waste removal mechanism 6 includes a support frame 61, a circular comb 62 and a second transmission assembly 63. The upper middle part of the base 1 is symmetrically provided with a support frame 61. The tops of the two support frames 61 are rotatably provided with circular combs 62 , and the fronts of the circular combs 62 are connected to the fronts of the first rotating shaft 43 on the right side with a second transmission assembly 63 .

[0058] People turn screw 513 and a row of writing brush penholders are all fixed between threaded plate 512 and slide plate 511, and nib is put into the lower water frame 2, start motor 42 again, the output shaft of motor 42 rear sides rotates and makes the first on the right side A rotating shaft 43 rotates, and the first rotating shaft 43 on the right side rotates to drive the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com