An assembled steel structure exterior wall

A steel structure and assembly technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of inconvenient splicing of external walls and single functions, and achieve the effects of avoiding human discomfort, increasing indoor temperature, and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

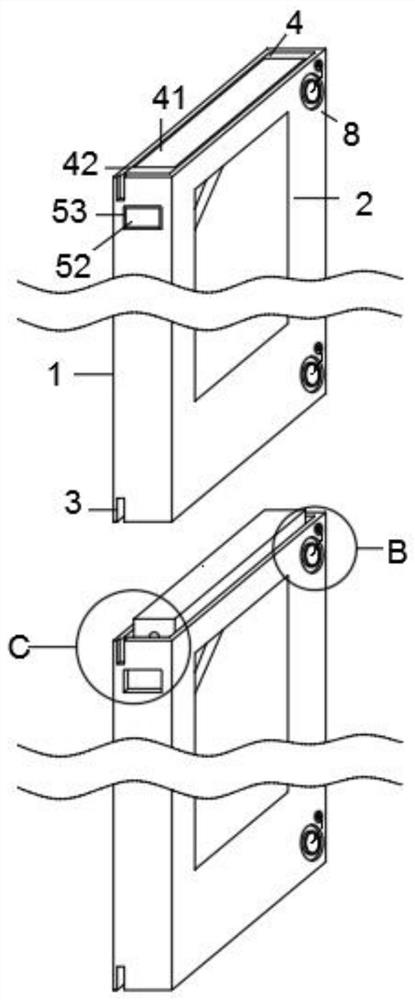

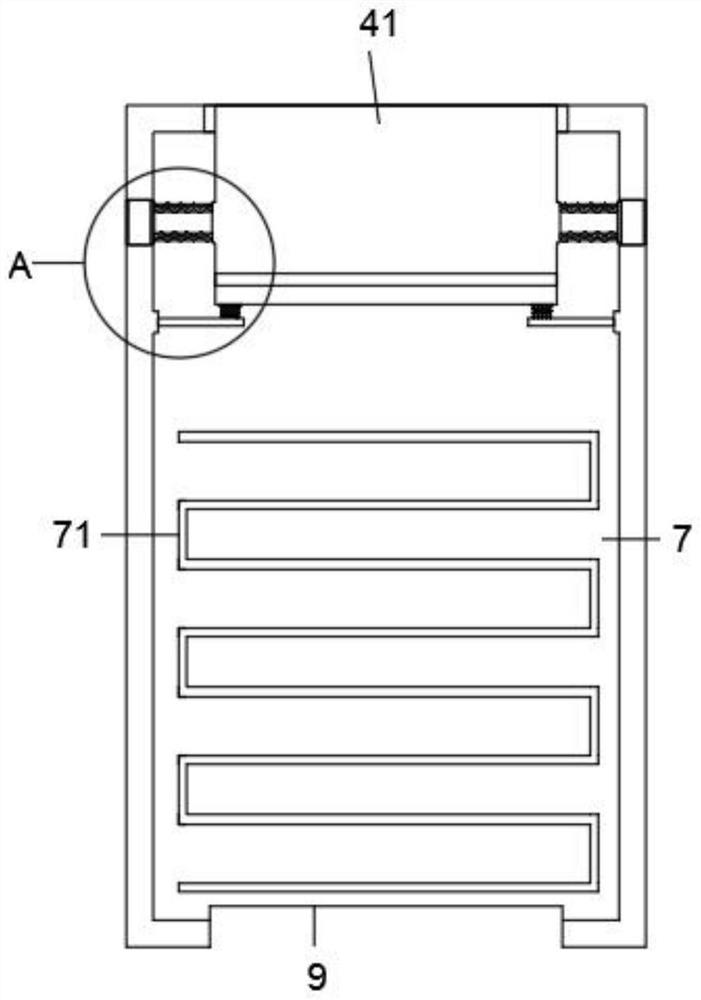

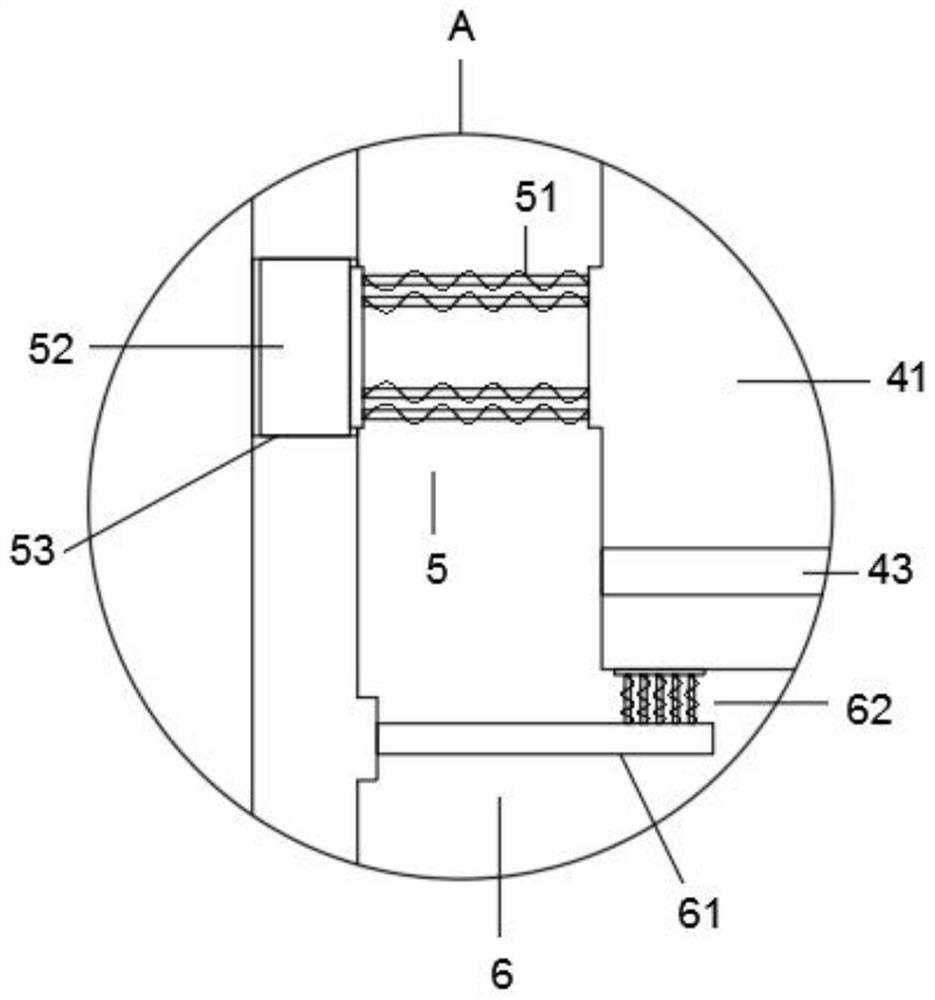

[0030] Such as Figure 1-5 As shown, the specific implementation mode adopts the following technical solutions: as figure 1 As shown, it includes exterior wall panels 1, sound insulation panels 2, and reinforcement grooves 3. By adding some welding fluid in the reinforcement grooves 3, the spliced exterior wall panels 1 are welded together through the reinforcement grooves 3 to increase splicing. stability, the sound insulation panels are fixedly embedded on both sides of the exterior wall panel 1, the reinforcement groove 3 is opened on the outer side wall of the bottom and top of the exterior wall panel 1, and the top of the exterior wall panel 1 is provided with a splicing mechanism 4, and the splicing mechanism 4 is inserted On the exterior wall panel 1, the two ends of the splicing mechanism 4 arranged inside the exterior wall panel 1 are connected with a side fixing mechanism 5. Part of the bottom inside the wall panel 1 is fixedly connected with a bottom power mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com