Anti-theft louver window sash

A shutter and window sash technology, applied in the field of shutters that are opened by rotation, can solve the problems of wasting profiles and discomfort, and achieve the effects of saving materials, preventing the entry of rainwater, and reducing the blocking of light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

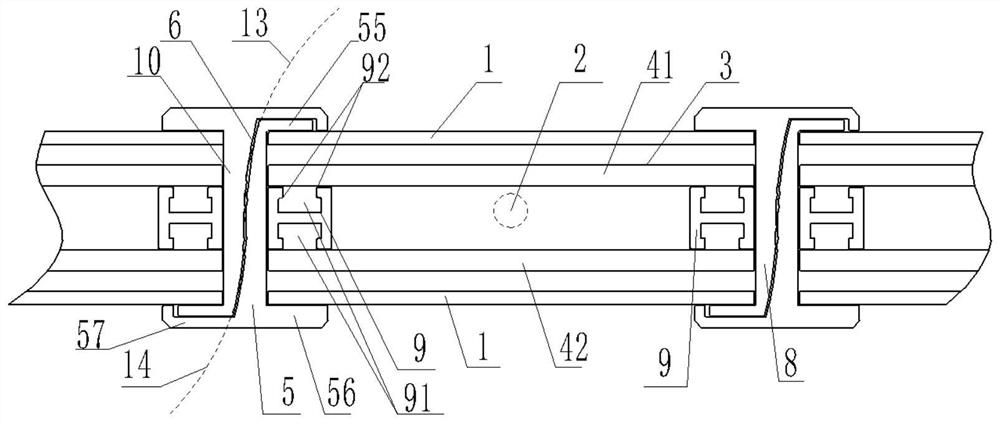

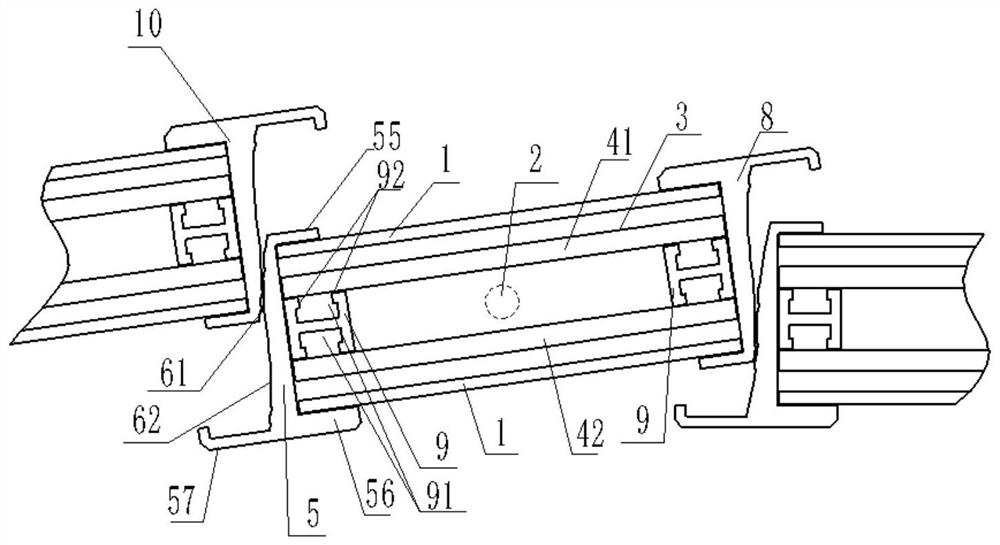

[0034] figure 1 It is a cross-sectional top view of the closed state of multiple shutters in this embodiment, figure 2 It is a cross-sectional top view of the opening process of multiple shutters in this embodiment. A kind of anti-theft shutter sash of the present embodiment, as figure 1 , figure 2 As shown, it includes a transverse profile 1 , a rotating shaft 2 , glasses 41 , 42 , a first vertical sealing strip 5 and a second vertical sealing strip 8 . The rotating shaft 2 is arranged on the transverse profile 1, and the transverse profile 1 is rotatably connected with the window frame through the rotating shaft 2; the transverse profile 1 is provided with a slot 3, and the glass 41 and the glass 42 are clamped In the card slot 3 , a transparent bracket 9 is arranged between the two layers of glass 41 , 42 , and the transparent bracket 9 is arranged on the left and right sides of the glass 41 , 42 . The transparent bracket 9 is a plate with an H-shaped cross-section, a...

Embodiment 2

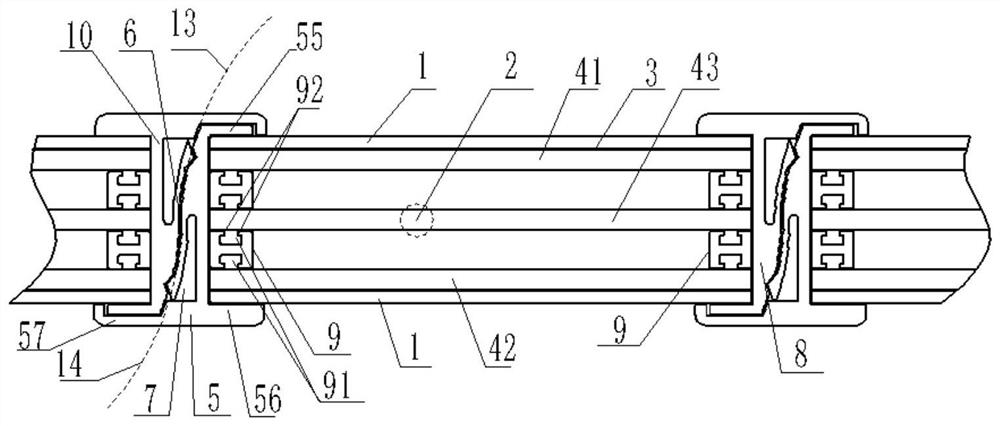

[0039] One difference between this embodiment and Embodiment 1 is that the glass in this embodiment has three layers, which are respectively glass 41, 42 and 43, and the transparent bracket 9 with a section of H-shaped plate is used to support and fix the three layers of glass. . Triple-glazed windows are better insulated. Another difference between this embodiment and Embodiment 1 is that the shutter sash of this embodiment is provided with an elastic plate on the vertical sealing strip. image 3 It is a cross-sectional top view of the closed state of multiple shutters in this embodiment, Figure 4 It is a cross-sectional top view of the opening process of multiple shutters in this embodiment. Such as image 3 , 4 As shown, a cavity 7 is provided on the thicker side of the sealing surface 6 of the first vertical sealing strip 5, and the outer part of the cavity 7 forms a first elastic plate 63 with a free end. The first elastic plate The free end of 63 is provided with a...

Embodiment 3

[0043] One difference between this embodiment and Embodiment 1 is that the shutter sash in this embodiment is provided with a first elastic plate and a second elastic plate on the vertical sealing strip. Figure 5 It is a cross-sectional top view of the closed state of multiple shutters in this embodiment, Image 6 It is a cross-sectional top view of the opening process of multiple shutters in this embodiment. Such as Figure 5 , 6 As shown, a cavity 7 is provided on the thicker side of the sealing surface 6 of the first vertical sealing strip 5, and the outer part of the cavity 7 forms a first elastic plate 63 with a free end. The first elastic plate The free end of 63 is provided with a V-shaped clamping platform 64 outward; the thinner side of the sealing surface 6 of the first vertical sealing strip 5 is provided with a V-shaped clamping groove 66 . A second elastic plate 68 parallel to the second side edge 56 is provided on the sealing surface 6, and one end of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com