Particle dynamic response test device and method based on electromagnetic control

A technology of dynamic response and electromagnetic control, which is applied in the field of research on the dynamic characteristics of granular materials, can solve problems such as not considering particles, adjusting particle contact or gaps, consistency, etc., to achieve clear data and eliminate contact or gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above-described electromagnetic-based particle dynamics response test apparatus and method according to the present invention will be described in detail below with reference to the accompanying drawings.

[0044]

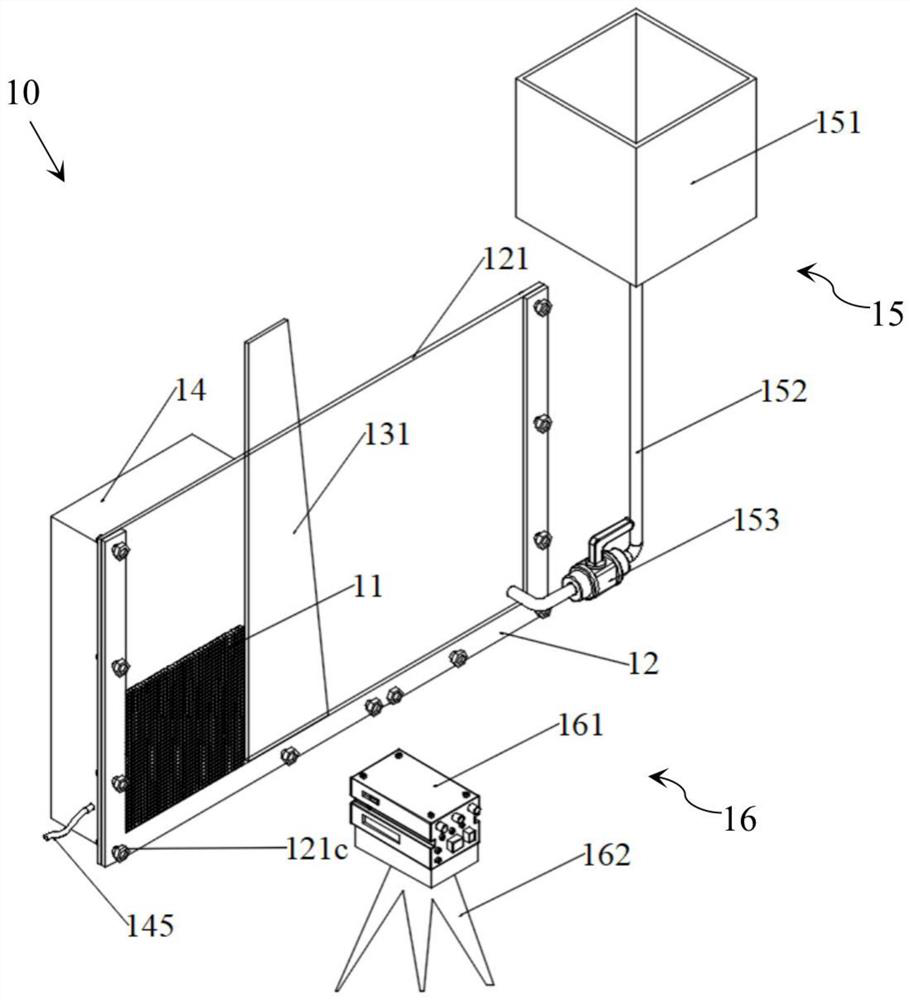

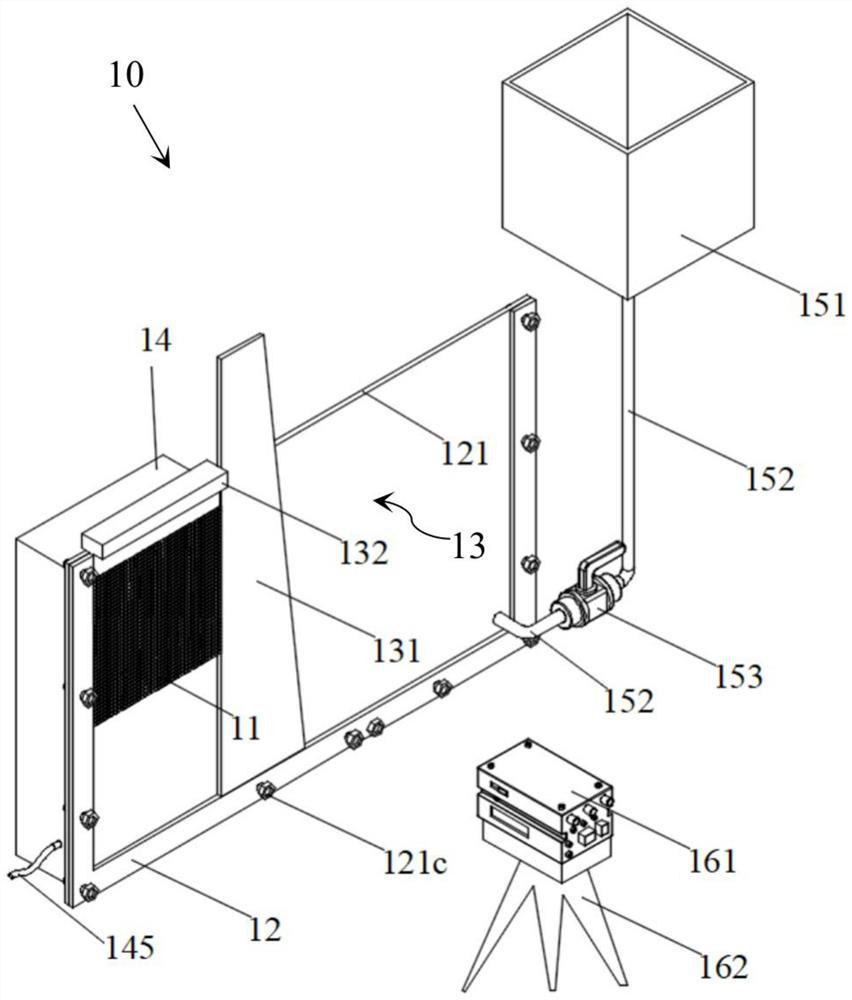

[0045] like Figure 1 to 7 As shown, the particle dynamics response test device 10 based on electromagnetic control includes a plurality of (sufficient test) particle unit 11, the particle flow tank 12, the baffle member 13, the electromagnetic suction cup 14, the hydrodynamic portion 15, and the image acquisition unit 16.

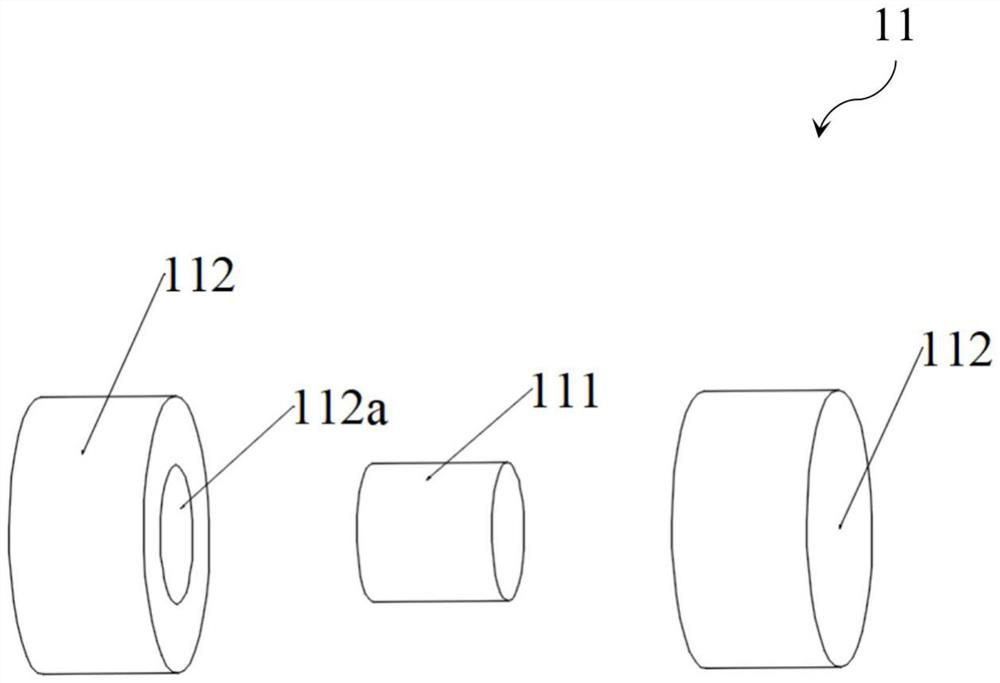

[0046] like image 3 As shown, the particle unit 11 includes an insert 111 and an inclusion 112. The insert 111 can produce magnetic properties under the action of electromagnetic. The inclusions 112 seal is wrapped outside the insertion body 111. In this embodiment, the particle unit 11 is a circular block, the insert 111 is a steel block, and the inclusion body 112 is a waterproof material. Further, in order to satisfy the fall collapse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com