Preparation method of artificial member for outer wall decoration

An exterior wall decoration, man-made technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

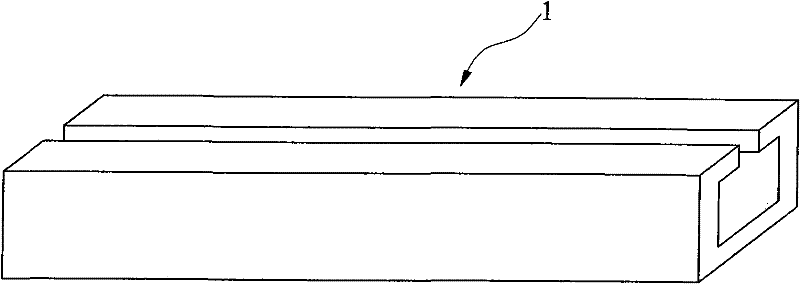

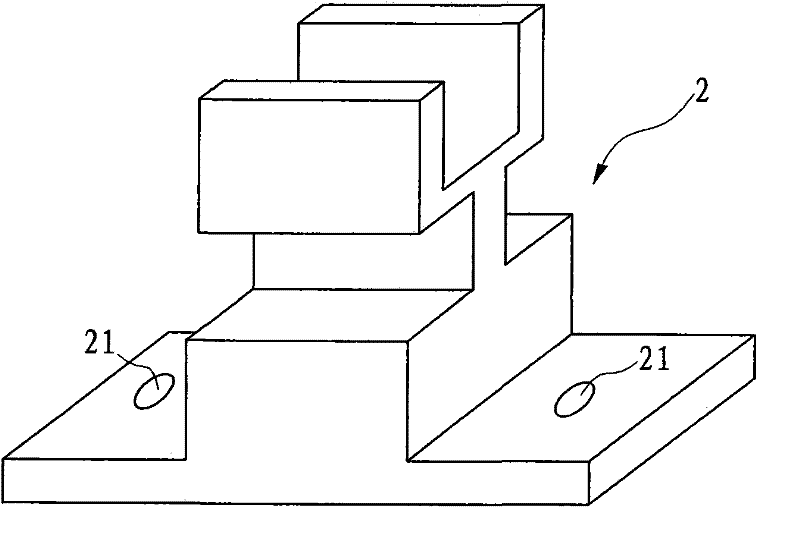

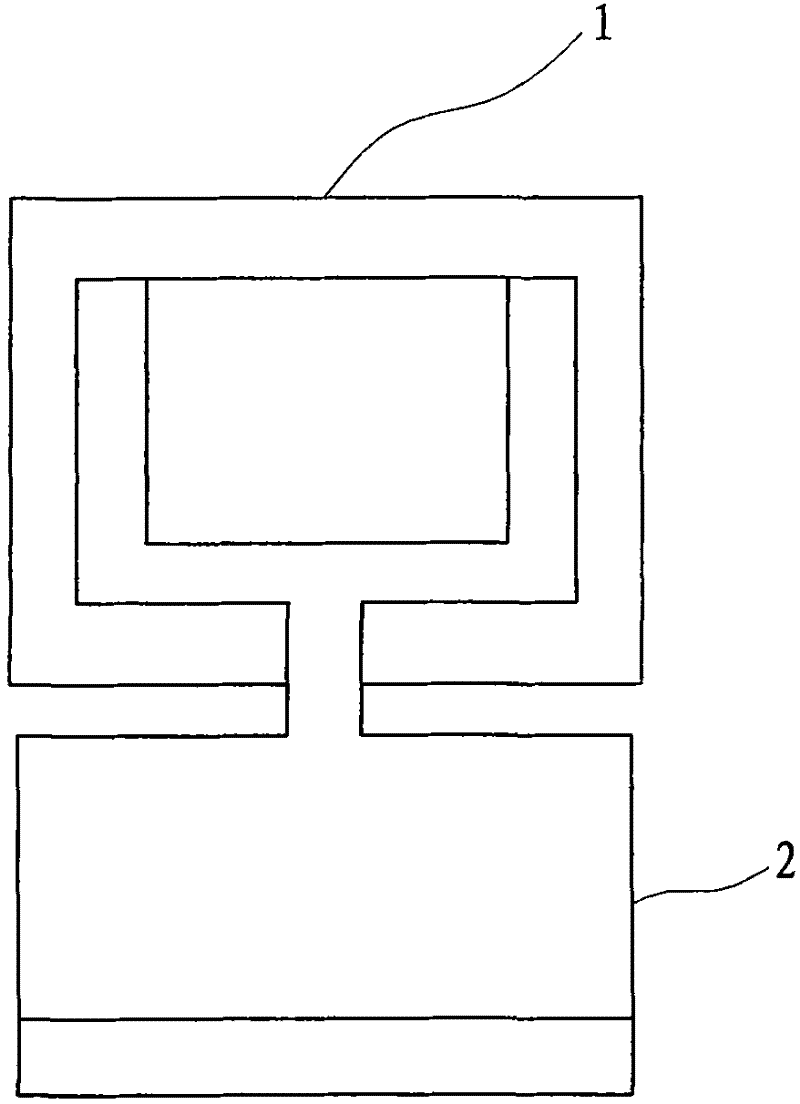

Image

Examples

preparation example Construction

[0030] The preparation method of the artificial component for exterior wall decoration comprises the following steps:

[0031] ① Mix the fillers in the raw materials according to the formulas designed for different varieties in the mixing tank, and then transport them to the hopper of the vacuum continuous casting machine through vertical and horizontal screws; put the resin, color paste, ultraviolet rays in the raw materials The absorber, light stabilizer and accelerator are stirred evenly in the stainless steel mixing tank, and then sent into the resin bucket of the vacuum continuous casting machine through the resin delivery pump; the curing agent is injected into the curing agent bucket of the vacuum continuous casting machine;

[0032] ②Start the vacuum continuous pouring machine, input the artificial stone pipe formula produced, start the raw material input and mixing program, and the mixed and stirred material is output from the discharge port and injected into the mold....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com