A leak detection system and control method for a water-cooled radiator

A water-cooled radiator and leak detection technology, applied in the field of detection systems, can solve the problems of expensive helium detection equipment, long detection time, unstable detection results, etc., and achieve high detection efficiency and accuracy, simple detection methods, and detection costs. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

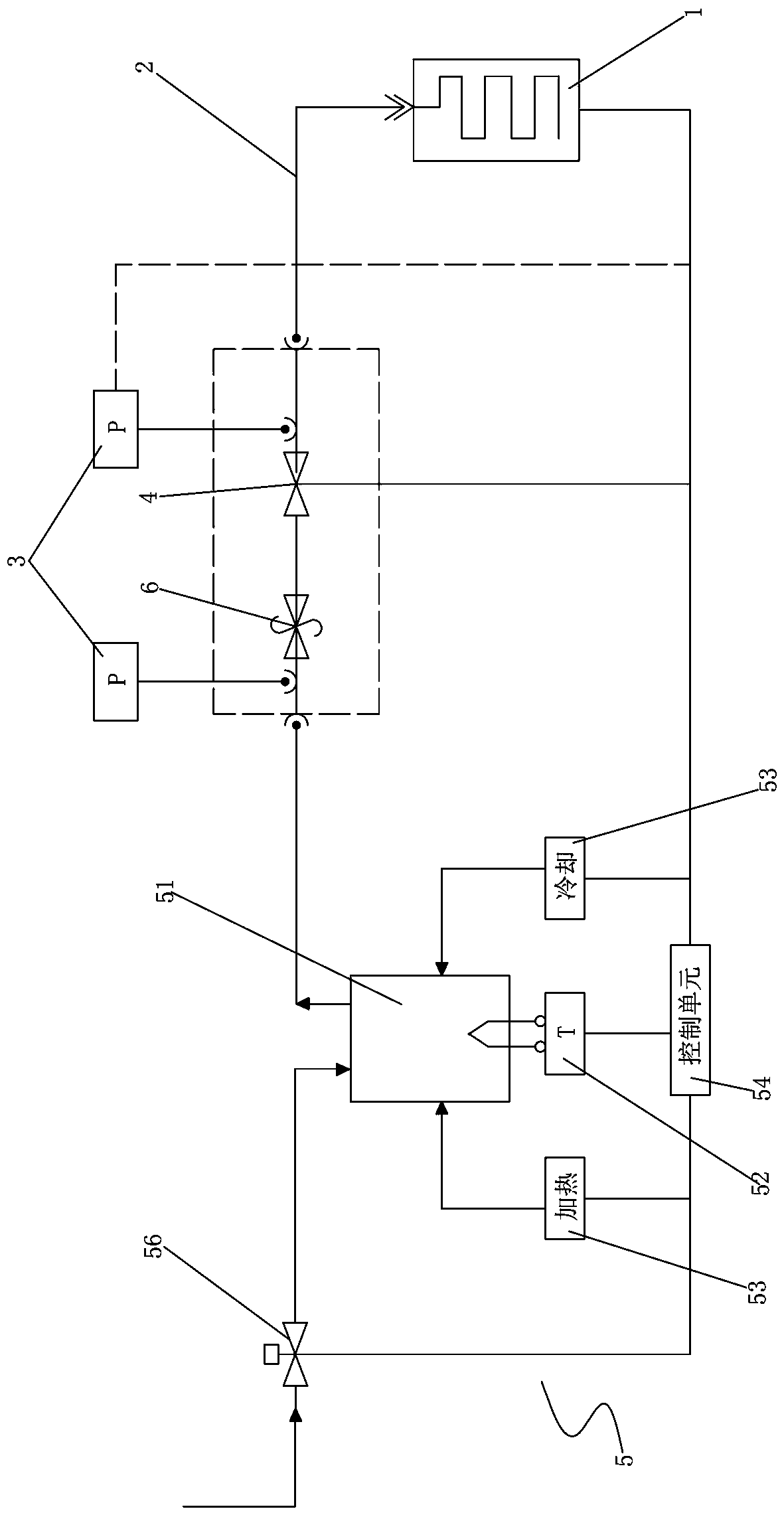

[0032] Specific implementation methods, such as figure 1 As shown, a leak detection system for a water-cooled radiator 1 according to the present invention mainly includes the following components: a water-cooled radiator 1, a circulation pipeline 2, a pressure detection sensor 3, an isolation valve 4, and a safety relief valve 6 , gas buffer storage tank 51, temperature detection unit 52, gas compensation unit 53, control unit 54 and pressure regulating valve 56;

[0033] During assembly, the water-cooled radiator 1, the isolation valve 4, the safety relief valve 6, the gas buffer storage tank 51, the gas compensation unit 53 and the pressure regulating valve 56 are sequentially connected in series through circulation management; A pressure detection sensor 3 is set on the circulation line 2 between the isolation valve 4 and the isolation valve 4; a pressure detection sensor 3 is also set between the isolation valve 4 and the gas buffer storage tank 51; then, a pressure detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com