A construction site trolley

A trolley, construction site technology, applied in trolleys, trolley accessories, single-axis trolleys, etc., can solve the problems of horizontal cavity carrying materials, getting out of trouble, and reducing work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

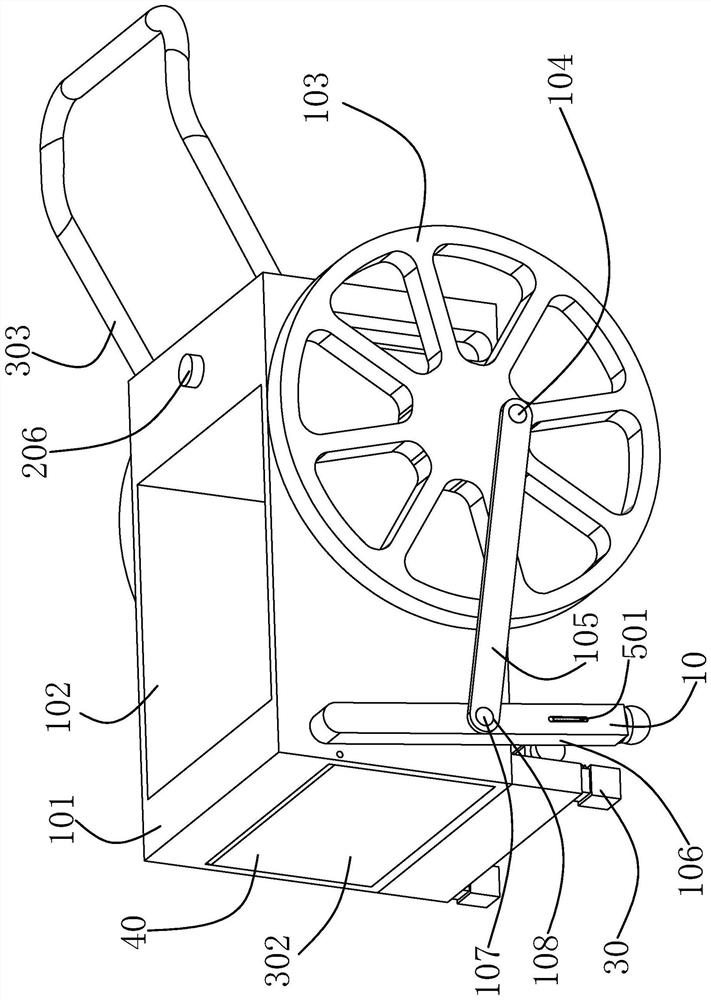

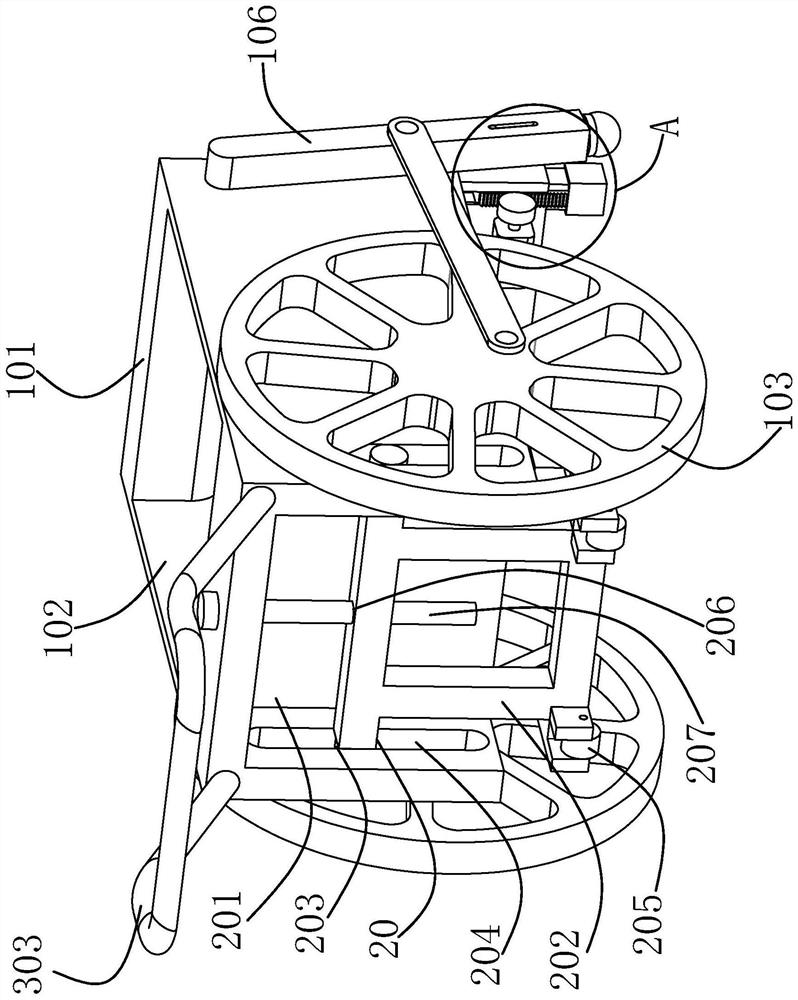

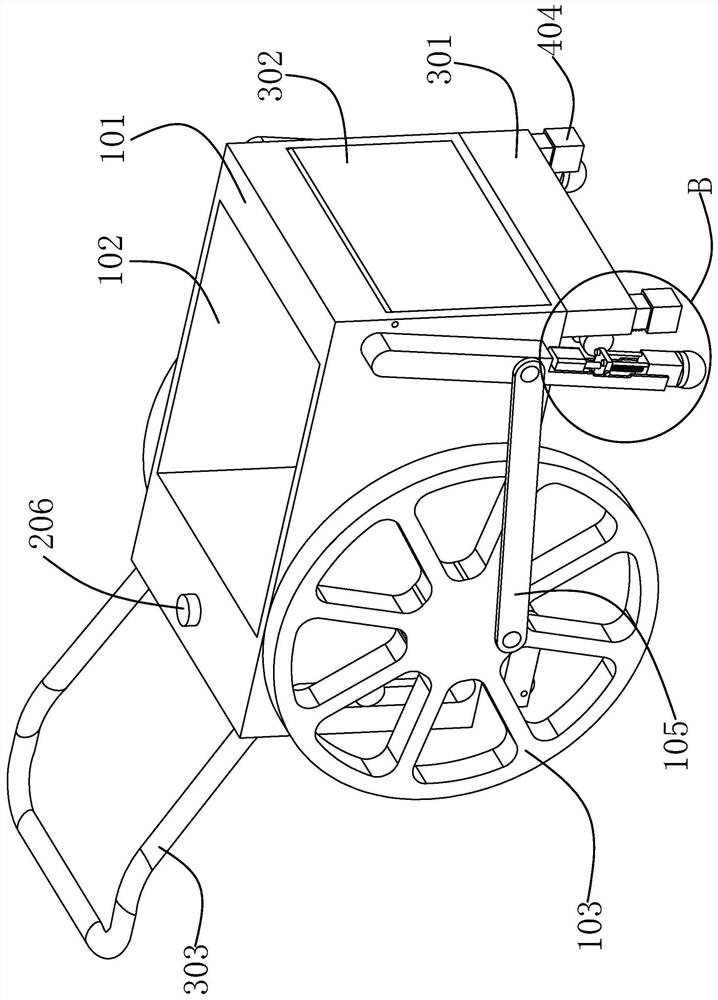

[0029] like Figure 1-Figure 5 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent. A construction site trolley of the present invention includes a car body 101, a material cavity 102 is arranged in the car body 101, and main wheels 103 are symmetrically arranged on both sides of the car body 101. The main wheels 103 and The car body 101 is rotated and matched, and one side of the car body 101 is provided with a driving assistance device 10 for assisting in propelling the vehicle forward. On the rotary opening device 40 for dumping materials, a parking device 30 is provided on the lower side of the rotary opening structure to support the vehicle to maintain balance when parking.

[0030] Beneficially, wherein, the driving assistance device 10 includes an eccent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com