A built-in anti-drop beam device

An anti-drop beam, embedded technology, used in bridges, bridge construction, bridge parts and other directions, can solve problems such as beam damage, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

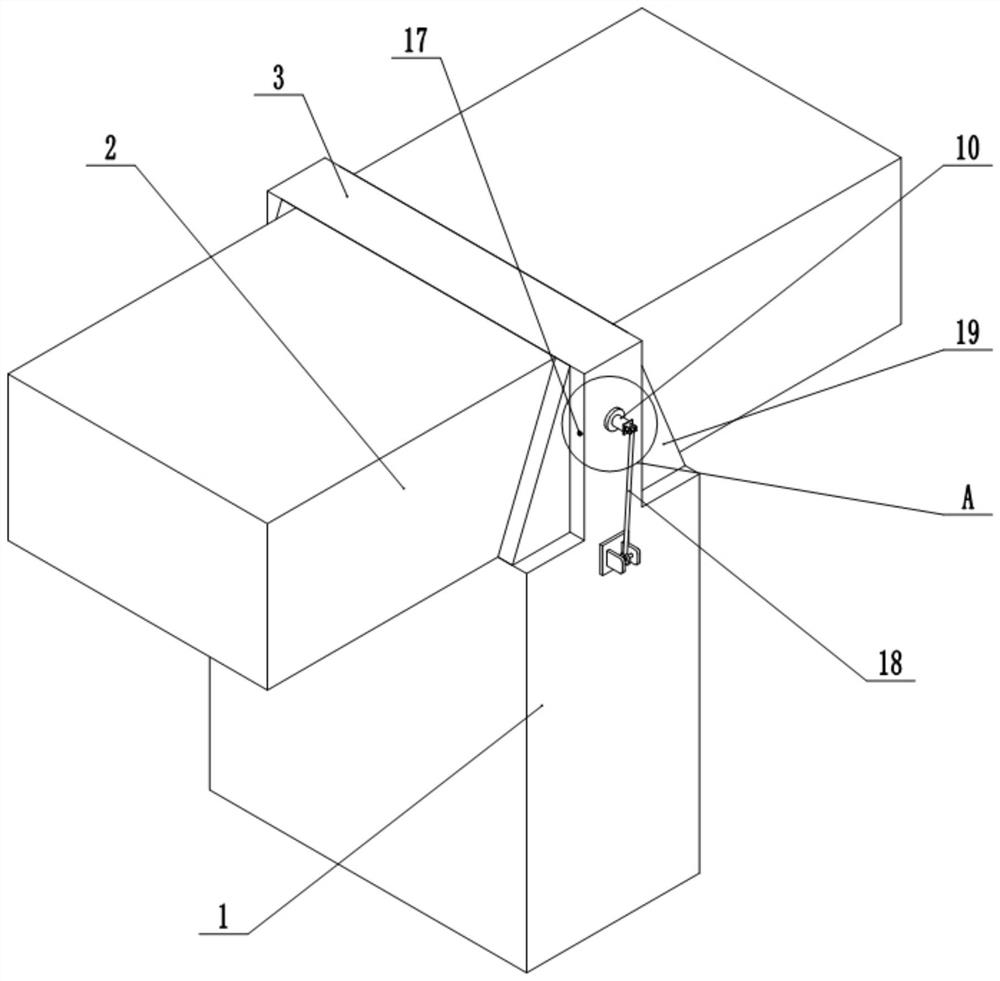

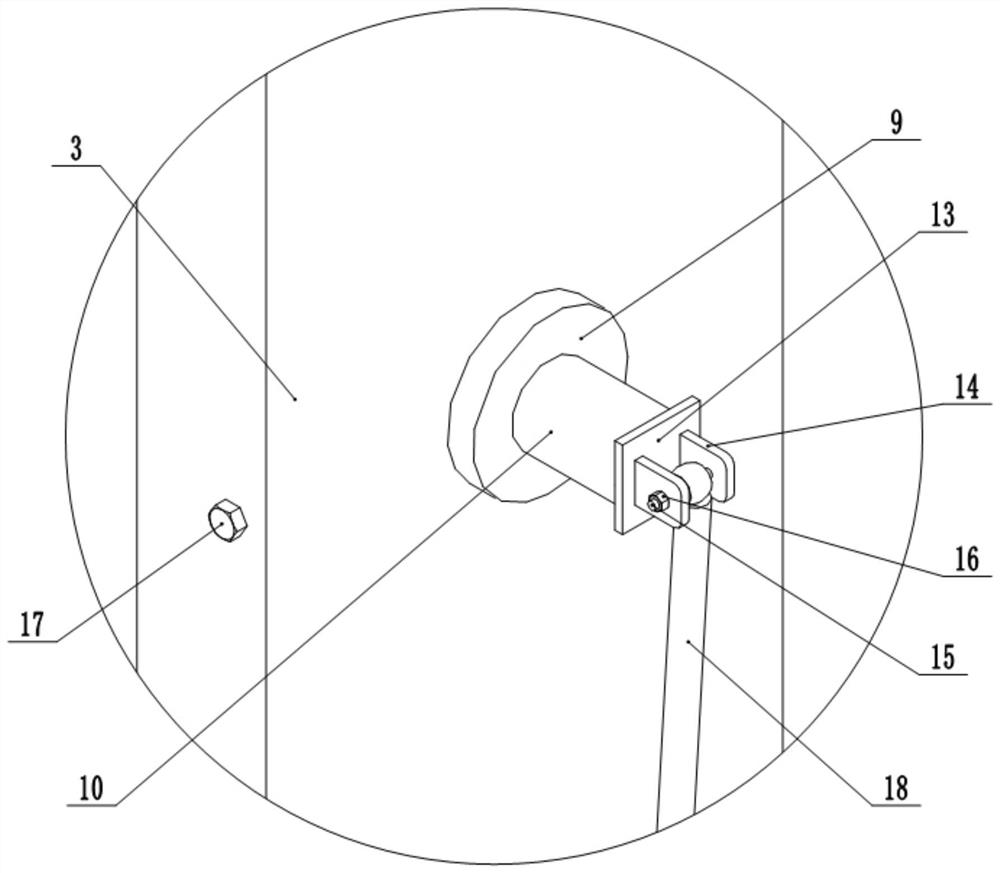

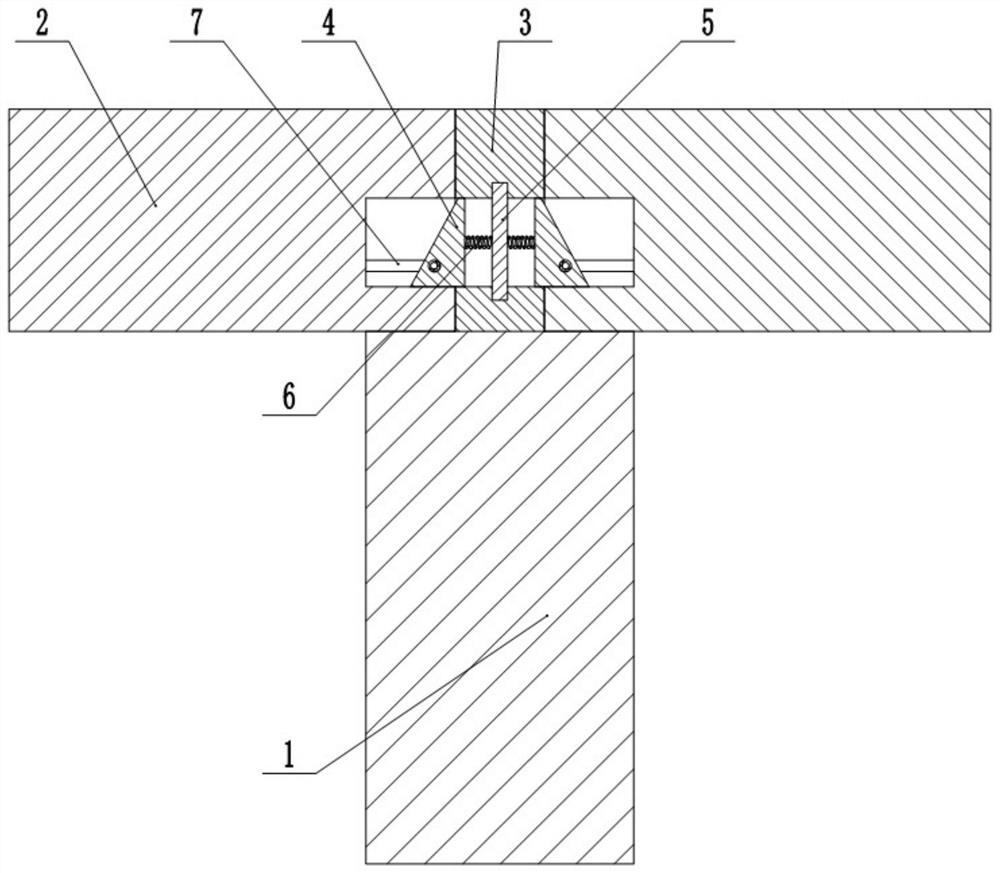

[0022] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown: an embedded anti-beam device including a pier 1, a partition plate 3 is fixed on the upper surface of the bridge 1, and the separator 3 is perpendicular to the bridge 1, and the separator 3 is provided with a horizontal set channel, in the channel The horizontally sliding connection of the finite column 4, and the end faces of the limit column 4 extend out of the channel, and the end faces of the limit column 4 are inclined inwardly, and vertical arrangement is vertically disposed on the limit column 4. The outer wall of the positioning column 5 is in contact with the outer wall of the positioning column 5, and the two ends of the positioning column 5 are connected to the inner wall of the passage, and the two ends of the chute are fixed to the positioning column 5. The spring 6 is placed on the bridge 1, and the beam body 2 is placed on the partition 3 symmetry, and the upper surface of the beam...

specific Embodiment approach

[0023] After the left side beam body 2 is lifted, the left end beam body 2 is placed in the process, and the beam body 2 is pressed down the inclined surface of the left end of the limit post 4, so that the limit column 4 slides to the right, the left end beam body 2 reaches the designation After the position, the limit column 4 slides in the initial position in the spring 6 and the positioning column 5, and the left end of the limit column 4 extends into the cavity of the left side beam 2; during this process, the limit column 4 left ends The limit rod 8 on the side slides into the groove in the inner wall of the cavity, until the limit rod 8 is in contact with the limit slot 7, at which time the limit rod 8 is elapsed and extension under the action of the spring 6. In the groove 7; after the right side beam body 2 is lifted, placed in the designated position, the right end beam body 2 is placed in the process, the beam body 2 extruded the inclined surface of the right end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com